Electronic component fault diagnosis model based on data analysis and prediction

A fault diagnosis model and technology of electronic components, applied in database models, relational databases, structured data retrieval, etc., can solve problems such as relying on manual processing, inability to mine business value, and time-consuming task cycles, reducing manual repetition. Inspect work, tap the potential of production quality control, ensure the effect of reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

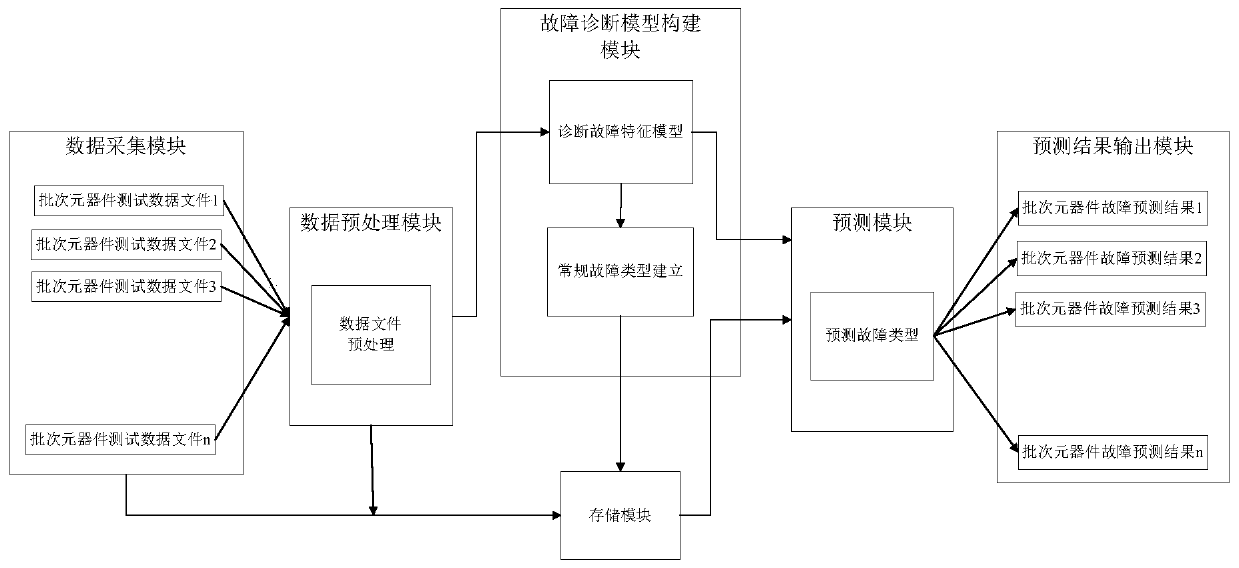

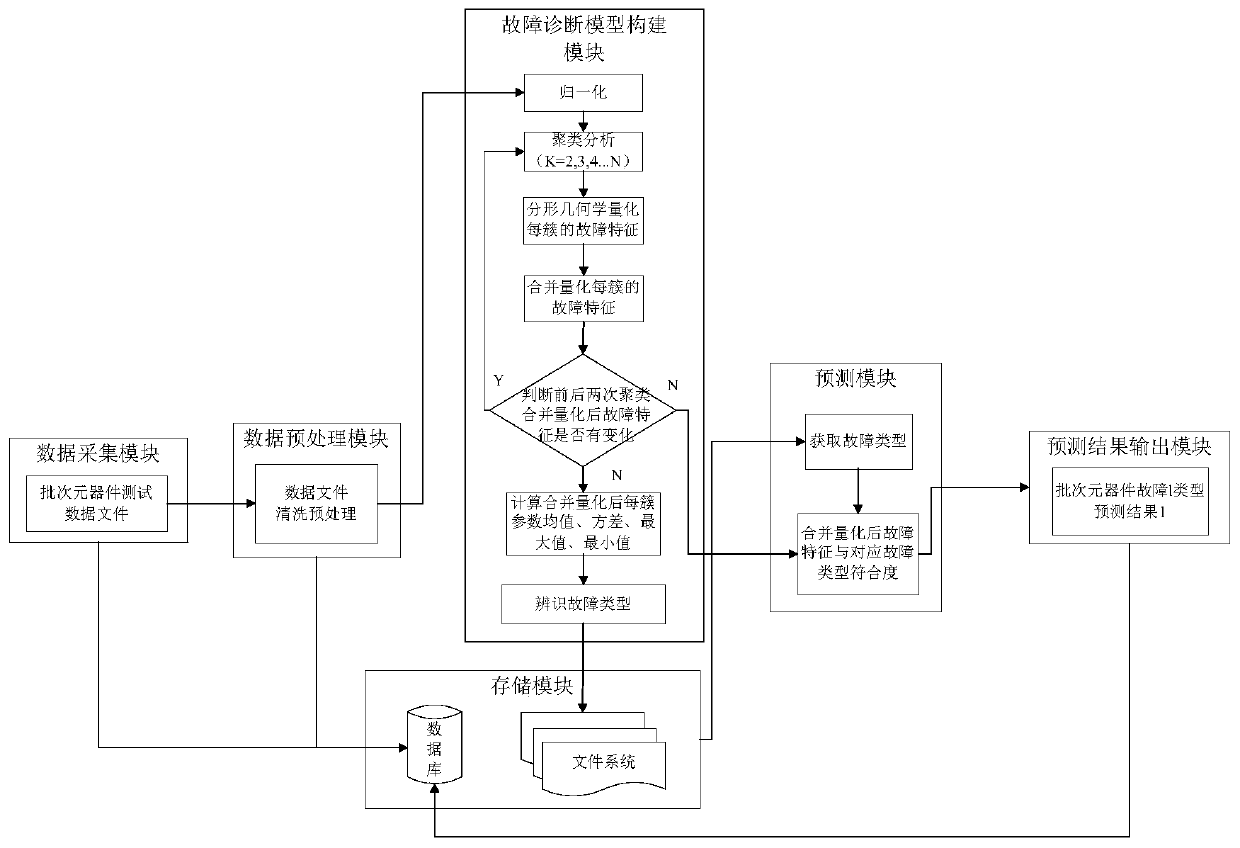

[0037] like figure 2 As shown, the implementation case includes: data acquisition module, data preprocessing module, fault diagnosis model building module, storage module, prediction module and prediction result output module.

[0038] The data acquisition module obtains the original batch of electronic component test data files, and each file contains a batch of component data, including the batch number, date, serial number, nominal voltage, and nominal capacitance of the batch of components , size, test voltage, evaluation, electrical performance parameters and tolerances of electrical performance parameters and other metadata.

[0039] The data preprocessing module preprocesses the received batch electronic component test data files, and performs data cleaning on the batch component data according to the tolerance range of the nominal value of each electrical performance parameter of the batch component, that is, each electronic component The performance parameters must be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com