Gear broken tooth laser cladding welding process optimization method based on ansys

A welding process and laser cladding technology, which is applied in the field of ansys-based laser cladding welding process optimization for gear broken teeth, can solve problems such as inconvenience, high stress in gear repair, and cracks in welding, so as to reduce costs, save manpower and material resources, The effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

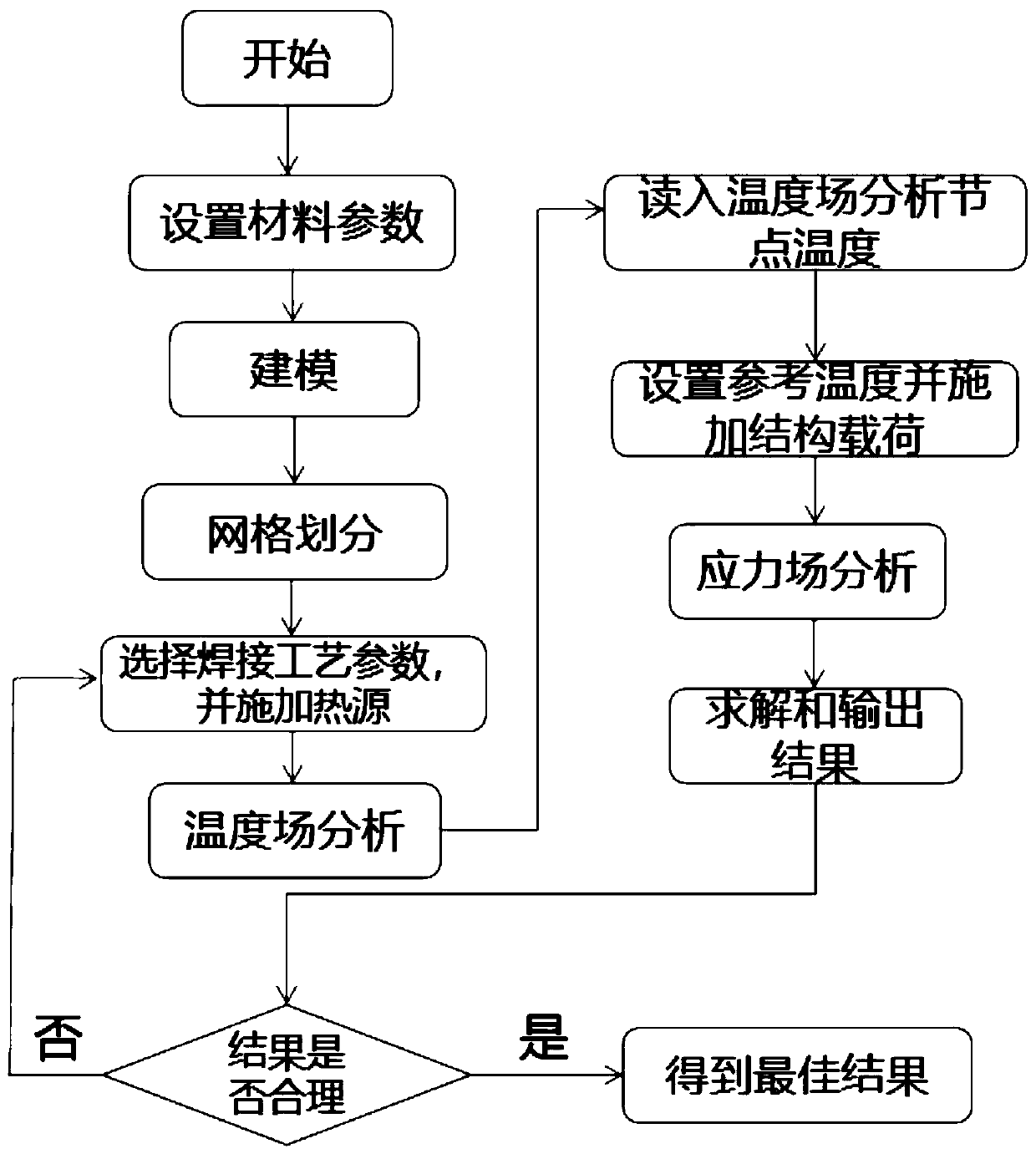

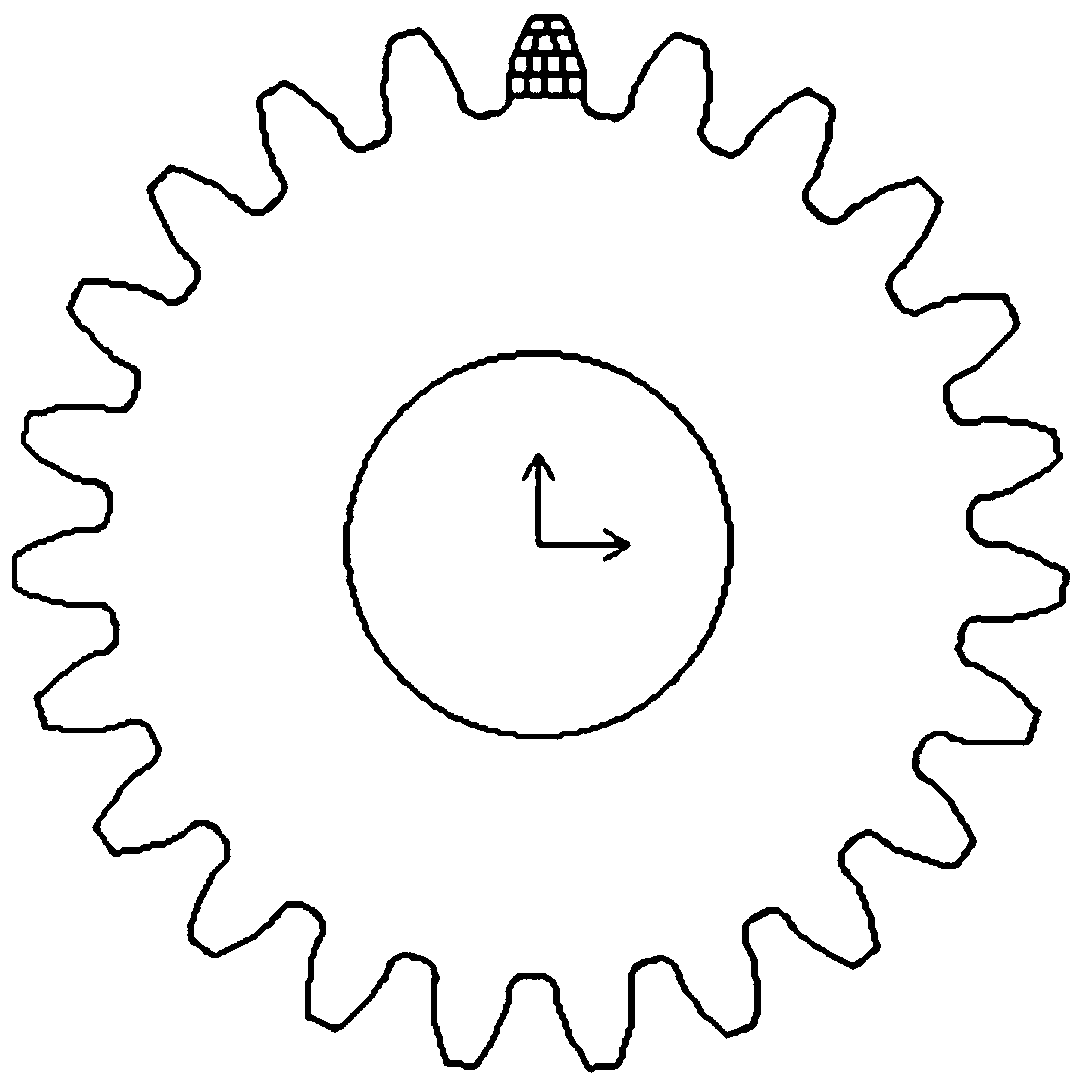

[0037]Embodiment 1: An ansys-based method for optimizing the laser cladding welding process of gear broken teeth, including steps: S1: determine the thermal analysis and stress analysis parameters of the gear material and weld metal powder; S2: determine the dimensional parameters of the gear, in cad Create a two-dimensional plan of the gear in , save it as an IGS file and import it into ansys; S3: define the thermal analysis unit and structural analysis unit, and then perform mesh division; S4: take the heat source model, select the heat source calculation formula, and then define the welding process parameters, including Welding current, voltage, speed, time; S5: On the basis of step S4, use the life and death unit to apply the heat source load, and the life and death unit is used to solve the nonlinear problem of the unit; S6: Use ansys to simulate different welding process parameters According to the temperature field, stress field and deformation, find out the minimum weld...

Embodiment 2

[0038] Embodiment 2: An ansys-based method for optimizing the laser cladding welding process of gear broken teeth, including steps:

[0039] S1: Determine the thermal analysis and stress analysis parameters of gear material and weld metal powder;

[0040] S2: Determine the size parameters of the gear, create a two-dimensional plan of the gear in cad, save it as an IGS file and import it into ansys;

[0041] S3: define the thermal analysis unit solid70 and the structural analysis unit Plane55, and then perform grid division;

[0042] S4: get the heat source model, select the heat source calculation formula, then define the welding process parameters, including welding current, voltage, speed, time;

[0043] S5: On the basis of step S4, use the "life and death unit" to apply heat source load;

[0044] S6: Use ansys to simulate the temperature field, stress field and deformation under different welding process parameters, and find out the minimum welding process parameters of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com