Two-dimensional motion mixing machine

A two-dimensional motion and mixer technology, which is applied to mixers, jitter/oscillation/vibration mixers, mixers with rotating containers, etc., can solve the problems of residual materials remaining in the cylinder, long mixing time, and low efficiency , to achieve the effect of quick discharge, rapid mixing, and sufficient and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

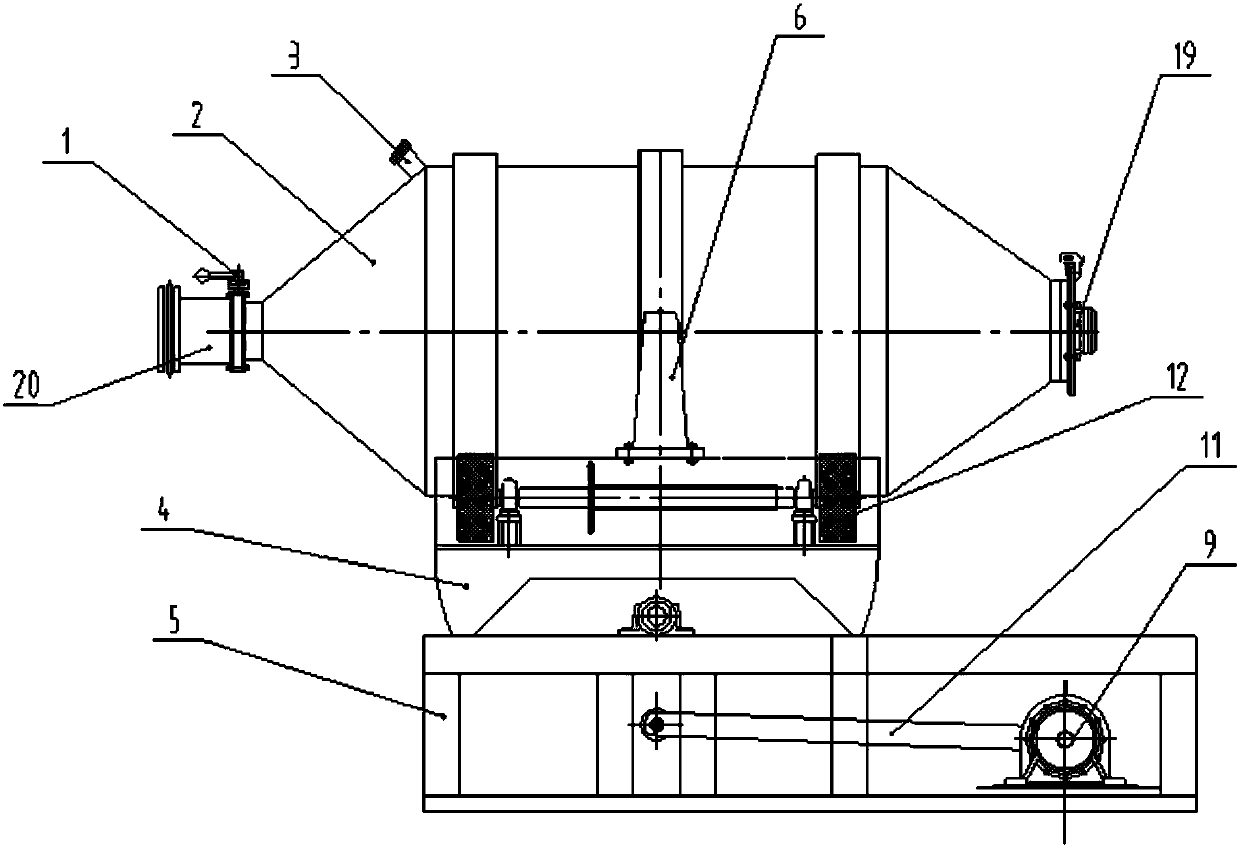

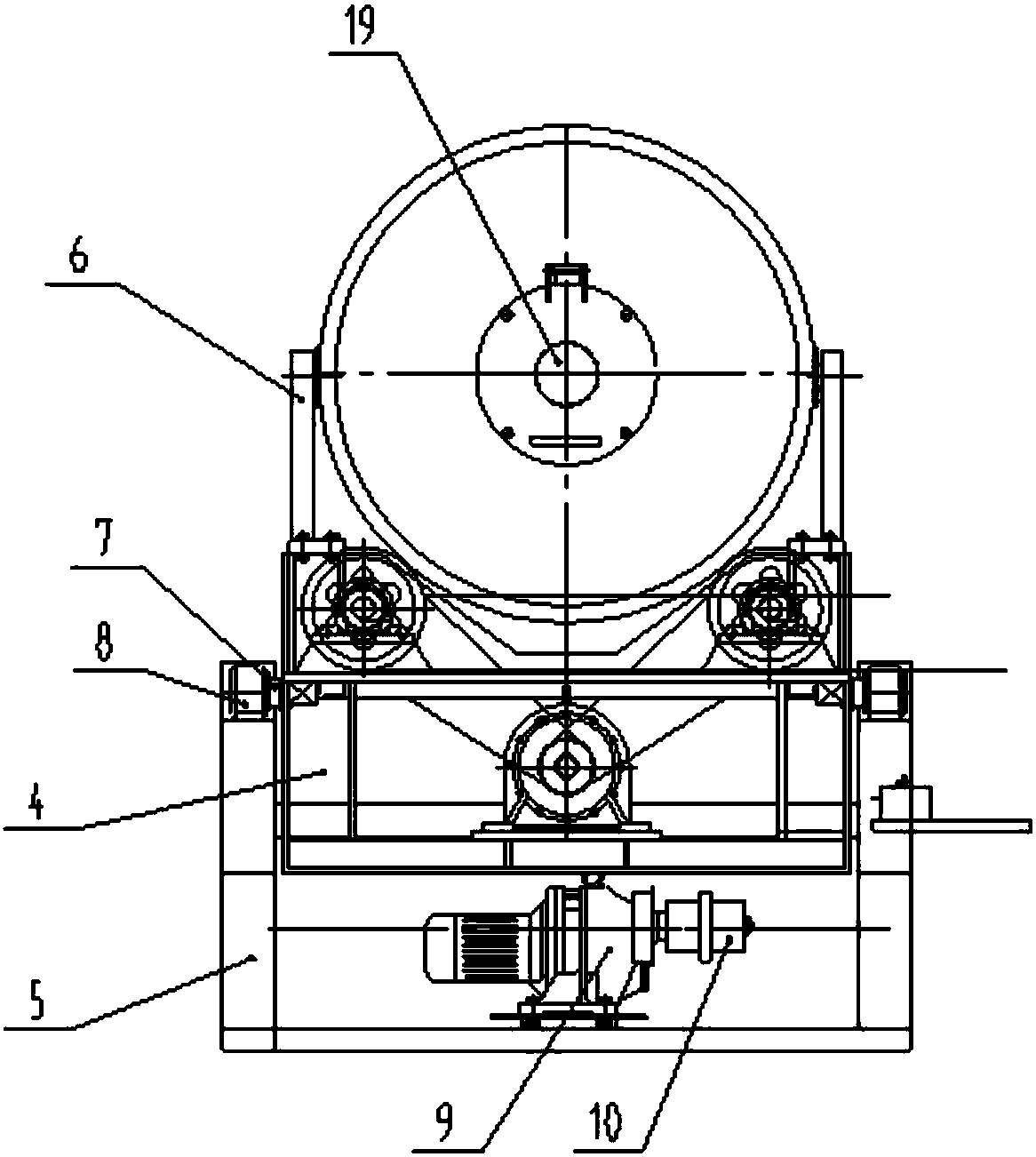

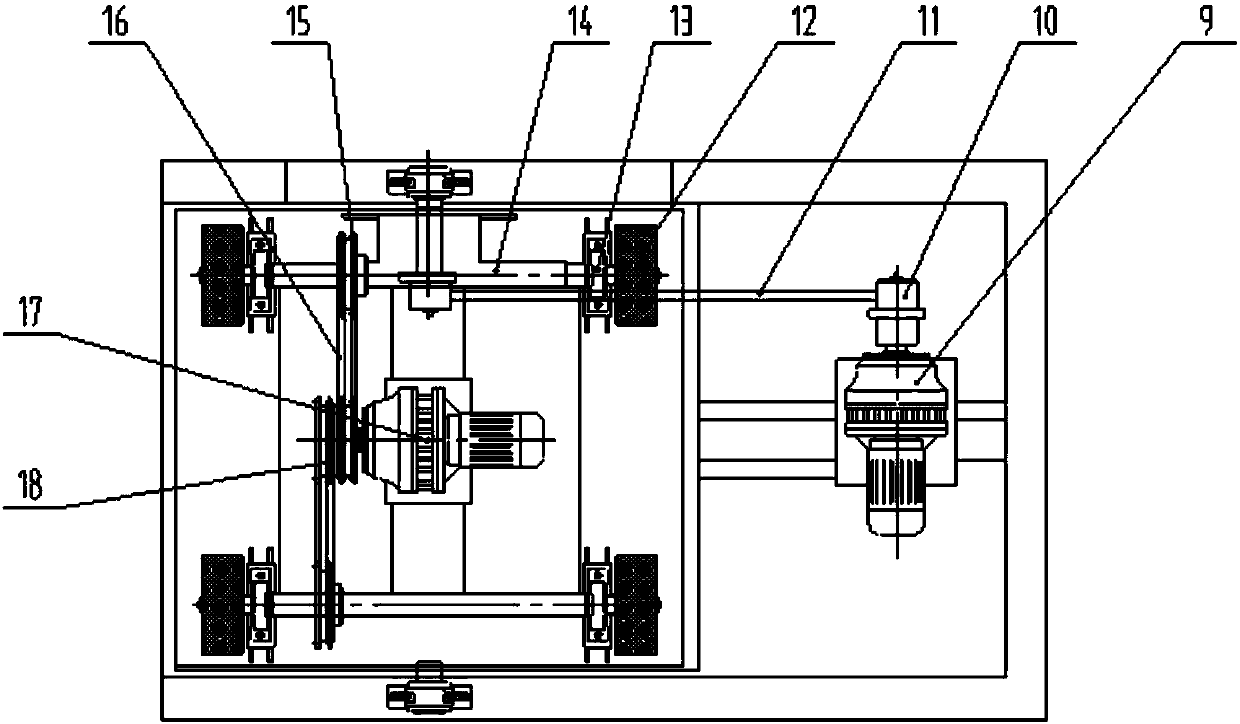

[0018] This embodiment provides a two-dimensional motion mixer with a structure such as figure 1 , figure 2 and image 3 As shown, it includes: a lower frame 5, an upper frame 4 and a barrel 2, the lower frame 5 is located at the bottom of the two-dimensional motion mixer, and one end of the lower frame 5 is provided with a swing reducer 9, and the swing reducer The axis of 9 is provided with swing shaft 10, and one end of swing shaft 10 and swing pull rod 11 is hinged, and the other end of swing pull rod 11 is hinged with upper frame 4, and upper frame 4 is positioned at the top of lower frame 5, and upper frame 4 It is connected with the lower frame 5 through the belt seat bearing 8 fixed on the lower frame 5 and the swing shaft head 7 fixed on the upper frame 4. The center position of the bottom of the upper frame 4 is provided with a rotation reducer 17, and the rotation reducer 17 A sprocket wheel 18 is arranged on the shaft of the upper frame 4, and a rotating shaft 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com