Low-rotating-speed micro-particle separation device

A particle separation, low-speed technology, used in centrifuges with rotating drums, centrifuges, etc., can solve problems such as easy failure and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

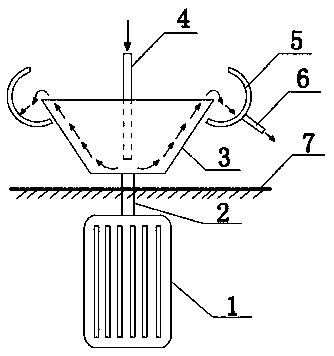

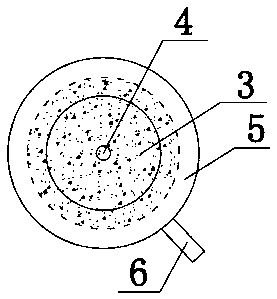

[0024] Embodiment 1, see Figure 1-2 , the present invention provides a technical solution: a low-speed micro-particle separation device, including a motor 1, a transmission shaft 2, a sample separation cup 3, a liquid inlet pipe 4, a sample collection tank 5, a liquid discharge pipe 6 and a sealing isolation layer 7 , the motor 1 is connected to the sample separation cup 3 through the transmission shaft 2, and the sample separation cup 3 is separated from the motor 1 by a sealing isolation layer 7, and the periphery of the cup opening of the sample separation cup 3 is provided with an annular A sample collection tank 5, the bottom of the sample collection tank 5 is provided with one or several funnel-shaped openings, and is connected to a liquid discharge pipe 6, and the inner cavity of the sample separation cup 3 is provided with a liquid inlet pipe 4 along the up and down direction;

[0025] The sealing isolation layer 7 can be extended as a housing or a flat plate that wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com