A heater protective cover welding aid

A protective cover and heater technology, applied in welding/cutting auxiliary equipment, welding equipment, auxiliary devices, etc., can solve the problems of reducing discomfort and people's discomfort, and achieve the effects of reducing trouble, shortening welding time, and facilitating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

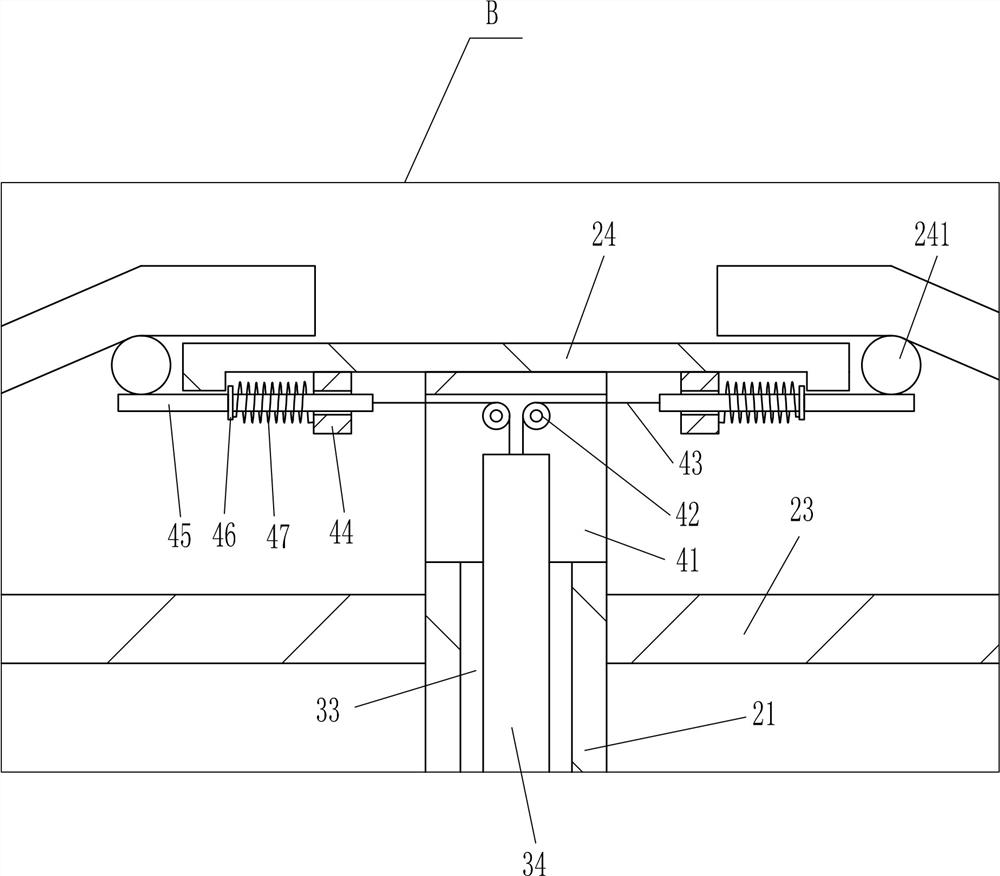

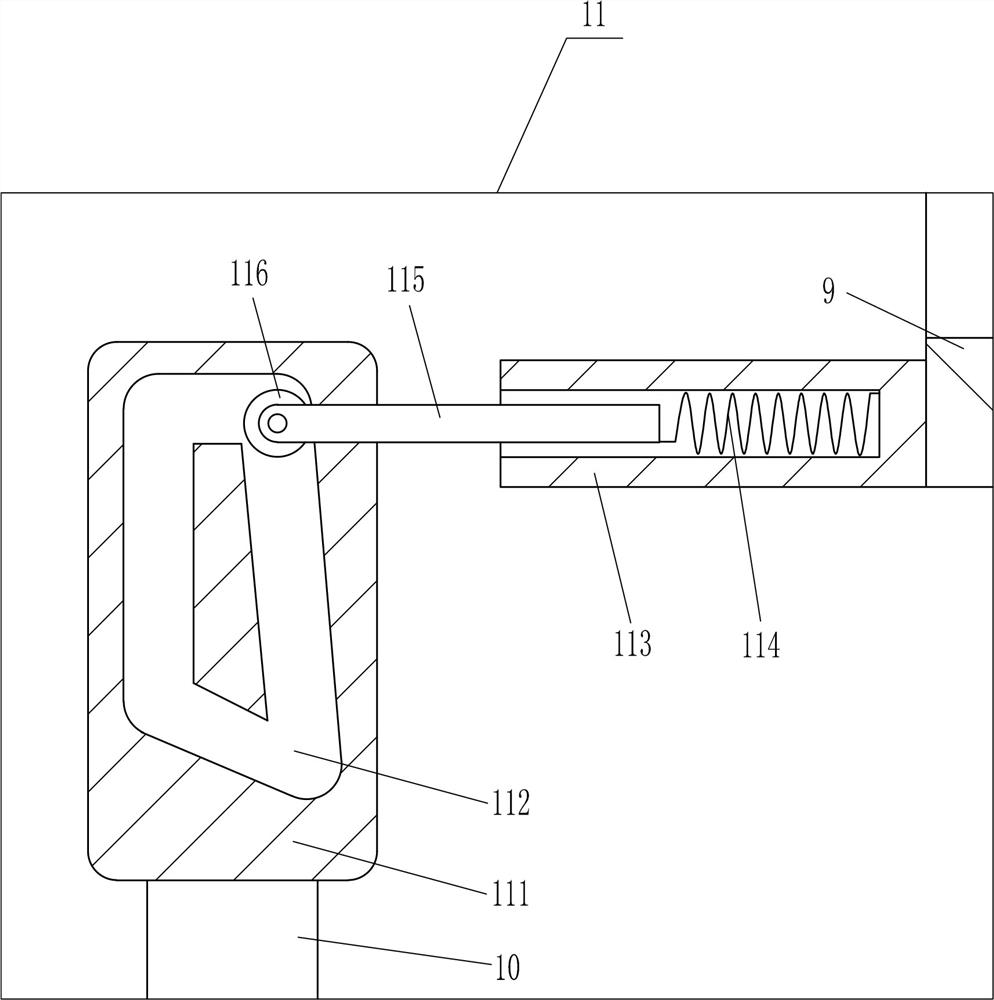

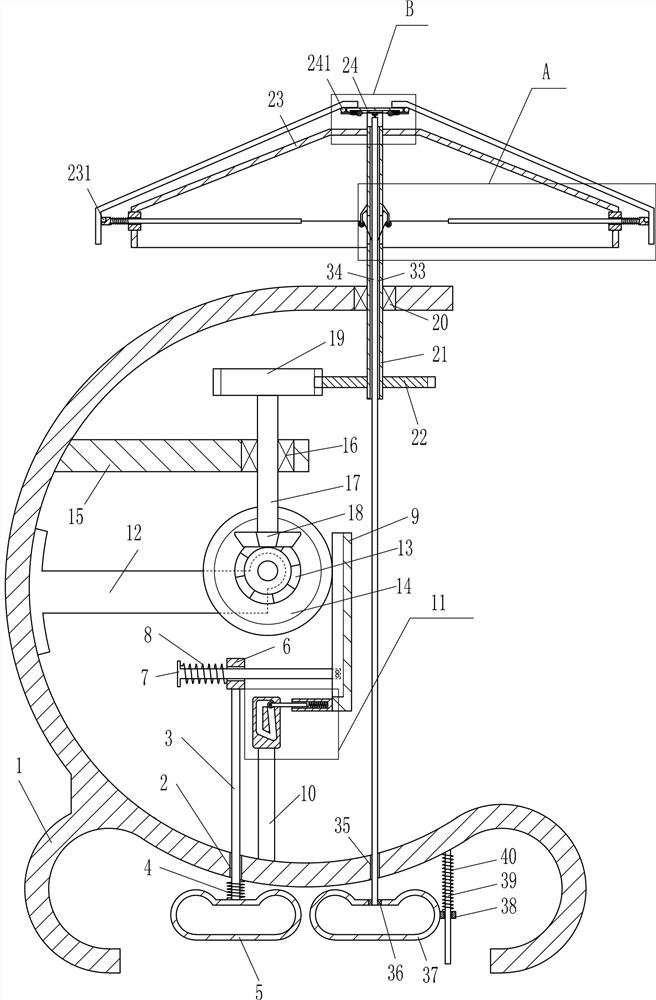

[0017] A heater shield welding aid such as Figure 1-2 As shown, it includes a first bracket 1, a guide rod 3, a first spring 4, a first pedal 5, a first sliding sleeve 6, a first sliding rod 7, a second spring 8, a rack 9, and a first rod 10 , rail device 11, support plate 12, first bevel gear 13, first gear 14, second bracket 15, first bearing 16, first rotating shaft 17, second bevel gear 18, second gear 19, second bearing 20 , the second rotating shaft 21, the third gear 22, the placement disc 23 and the support plate 24, the left side of the first support 1 bottom has the first guide hole 2, and the first guide hole 2 is movable with a guide rod 3, and the guide rod 3 The lower part is wound with a first spring 4, the upper end of the first spring 4 is connected with the first bracket 1, the lower end of the guide rod 3 is provided with a first pedal 5, the first pedal 5 is located at the lower part of the first bracket 1, and the upper end of the guide rod 3 is provided ...

Embodiment 2

[0019] A heater shield welding aid such as Figure 1-2As shown, it includes a first bracket 1, a guide rod 3, a first spring 4, a first pedal 5, a first sliding sleeve 6, a first sliding rod 7, a second spring 8, a rack 9, and a first rod 10 , rail device 11, support plate 12, first bevel gear 13, first gear 14, second bracket 15, first bearing 16, first rotating shaft 17, second bevel gear 18, second gear 19, second bearing 20 , the second rotating shaft 21, the third gear 22, the placement disc 23 and the support plate 24, the left side of the first support 1 bottom has the first guide hole 2, and the first guide hole 2 is movable with a guide rod 3, and the guide rod 3 The lower part is wound with a first spring 4, the upper end of the first spring 4 is connected with the first bracket 1, the lower end of the guide rod 3 is provided with a first pedal 5, the first pedal 5 is located at the lower part of the first bracket 1, and the upper end of the guide rod 3 is provided w...

Embodiment 3

[0022] A heater shield welding aid such as Figure 1-3 As shown, it includes a first bracket 1, a guide rod 3, a first spring 4, a first pedal 5, a first sliding sleeve 6, a first sliding rod 7, a second spring 8, a rack 9, and a first rod 10 , rail device 11, support plate 12, first bevel gear 13, first gear 14, second bracket 15, first bearing 16, first rotating shaft 17, second bevel gear 18, second gear 19, second bearing 20 , the second rotating shaft 21, the third gear 22, the placement disc 23 and the support plate 24, the left side of the first support 1 bottom has the first guide hole 2, and the first guide hole 2 is movable with a guide rod 3, and the guide rod 3 The lower part is wound with a first spring 4, the upper end of the first spring 4 is connected with the first bracket 1, the lower end of the guide rod 3 is provided with a first pedal 5, the first pedal 5 is located at the lower part of the first bracket 1, and the upper end of the guide rod 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com