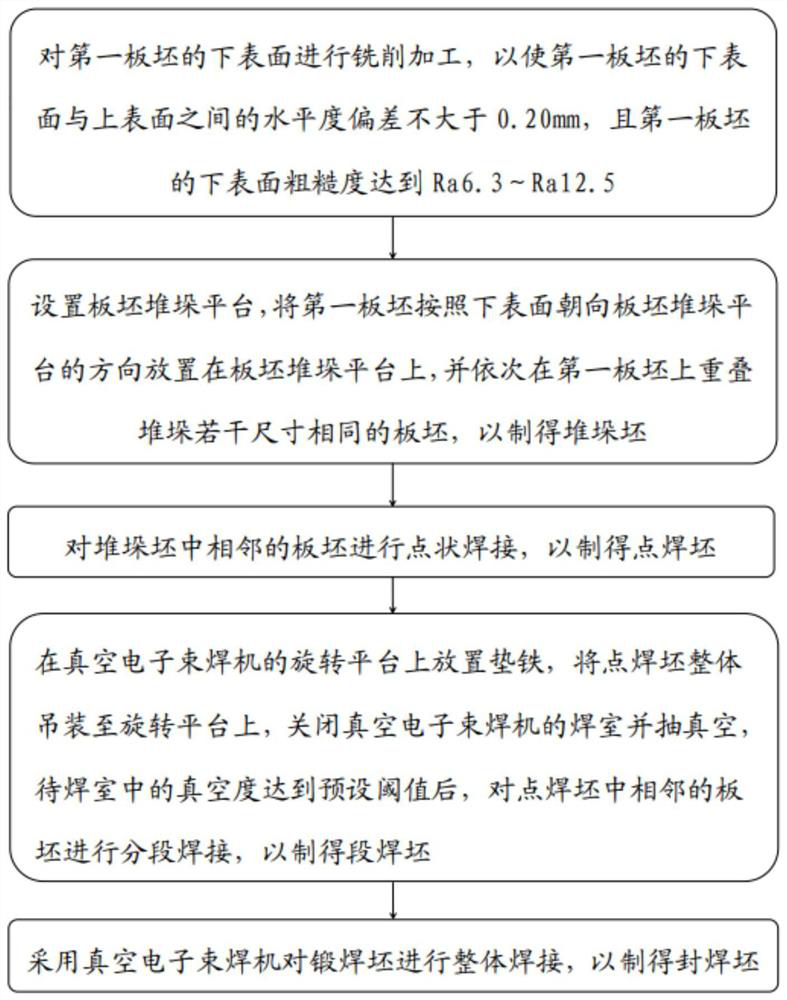

A Method of Improving the Efficiency of Vacuum Electron Beam Sealing and Welding of Multilayer Slabs

A vacuum electron beam and slab technology, which is applied to electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the welding seam of the sealing and welding blank is easy to crack, and the stacking and sealing and welding operations cannot be carried out at the same time, which affects the sealing and welding problems such as billet production efficiency, to improve efficiency, reduce the risk of weld cracking, and improve internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

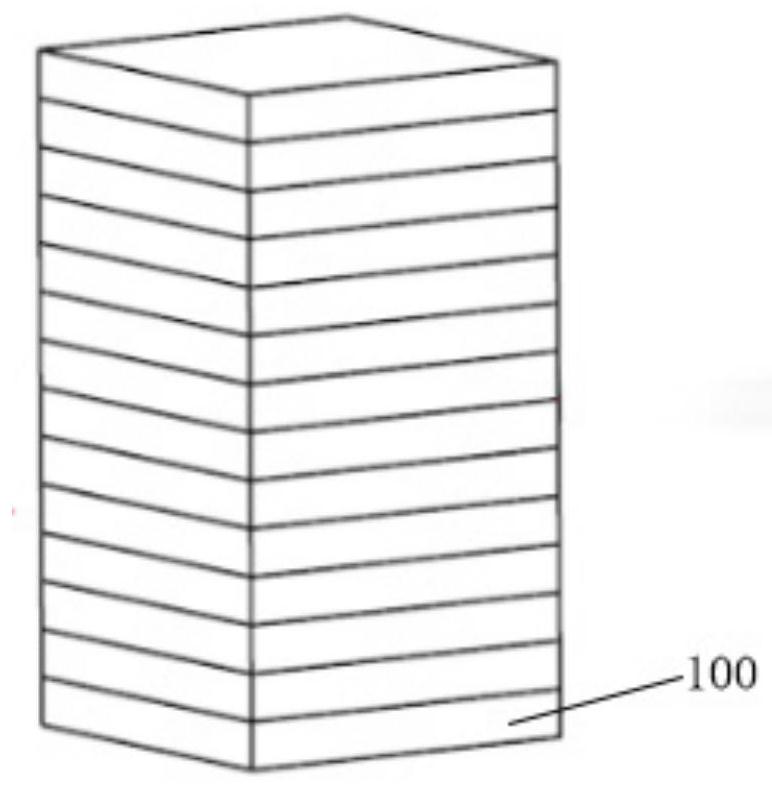

[0058] The material of the sealing and welding blank is low-alloy carbon steel, and the number of layers of the sealing and welding blank is 9 layers. Spot-weld the stacked blanks using MIG gas shielded welding, the shielding gas is 100% Ar gas, and only the short side of each layer of blanks is spot-welded, and each short side is spot-welded at 3 places, evenly distributed, and each place is spot-welded Length≤10mm. The overall size of the stacked blanks after spot welding is: width 1600mm×length 2180mm×height 2645mm.

[0059] Lift the spot-welded blank as a whole on the rotating platform of the vacuum electron beam welding machine. In order to ensure that the interface of the spot-welded blank is parallel to the axis of the electron beam, the lower surface of the first slab has been milled, and the lower and upper surfaces of the first slab Level deviation ≤ 0.20mm, lower surface roughness reaches Ra6.3. The spot welding blank is placed on the 4 equal-height pad irons on t...

Embodiment approach 2

[0065] The material used for sealing and welding blanks is austenitic stainless steel, and the number of layers of sealing and welding blanks is 13. The stacked blanks are spot welded by MIG gas shielded welding, the shielding gas is 100% Ar gas, only the short sides are spot welded between adjacent blanks, and each short side is spot welded at 2 places, evenly distributed, and each place Spot welding length ≤ 10mm. The overall size of the stacked blanks after spot welding is: width 1130mm×length 1530mm×height 2509mm.

[0066] Hoist the spot-welded slab as a whole on the rotating platform of the vacuum electron beam welding machine. In order to ensure that the interface of the spot-welded slab is parallel to the axis of the electron beam, the lower surface of the first slab has been milled, and the lower and upper surfaces of the slab are horizontal Degree deviation ≤0.20mm, lower surface roughness reaches Ra12.5. The spot-welded slab is placed on the 4 equal-height pad iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com