Multifunctional ecological outer wall and preparation method thereof

A multifunctional and ecological technology, applied in chemical instruments and methods, walls, household walls, etc., can solve the problems of dry air without effective improvement, unable to meet waterproof requirements, unable to fully utilize resources, etc., to achieve low cost and savings The effect of resources, solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

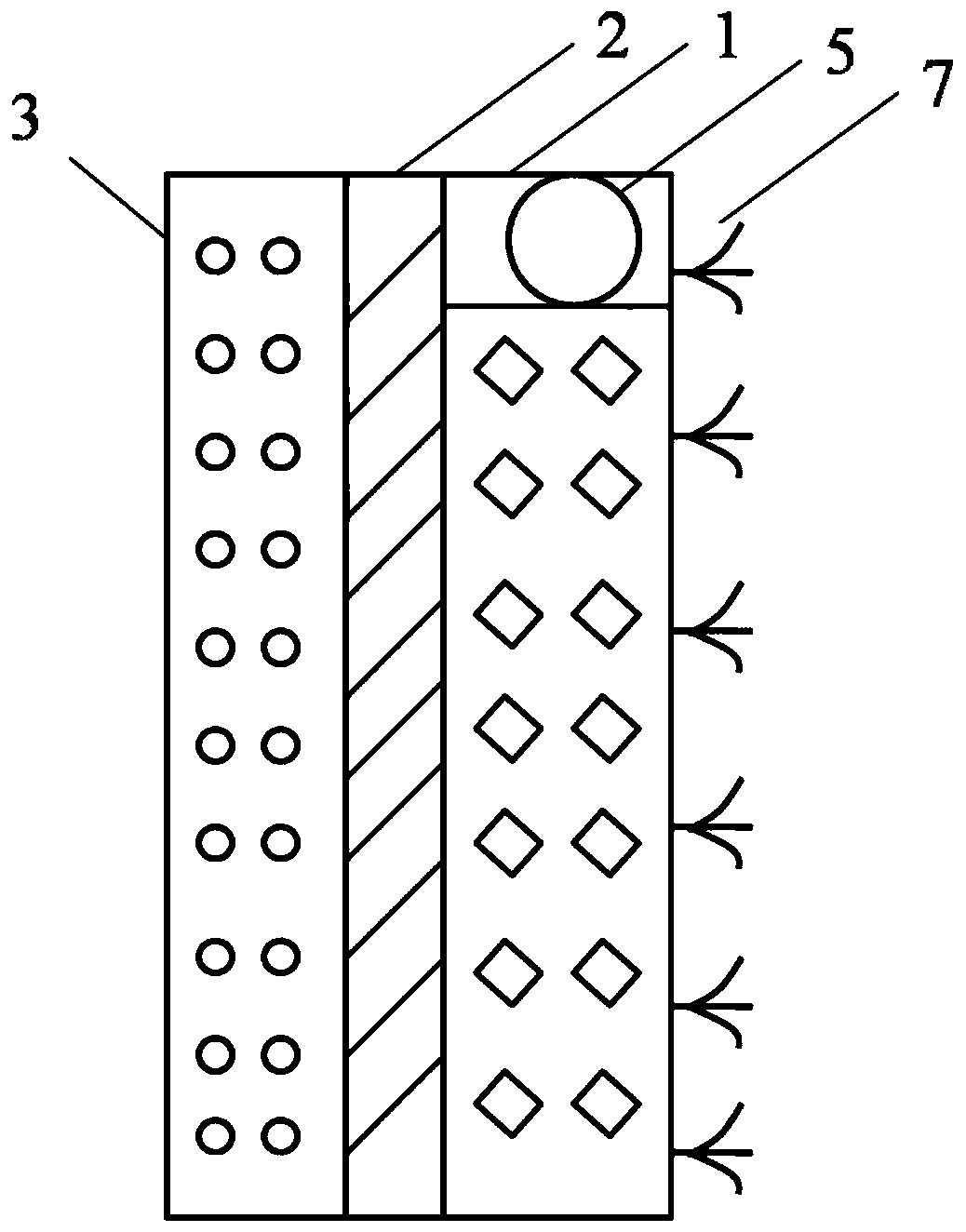

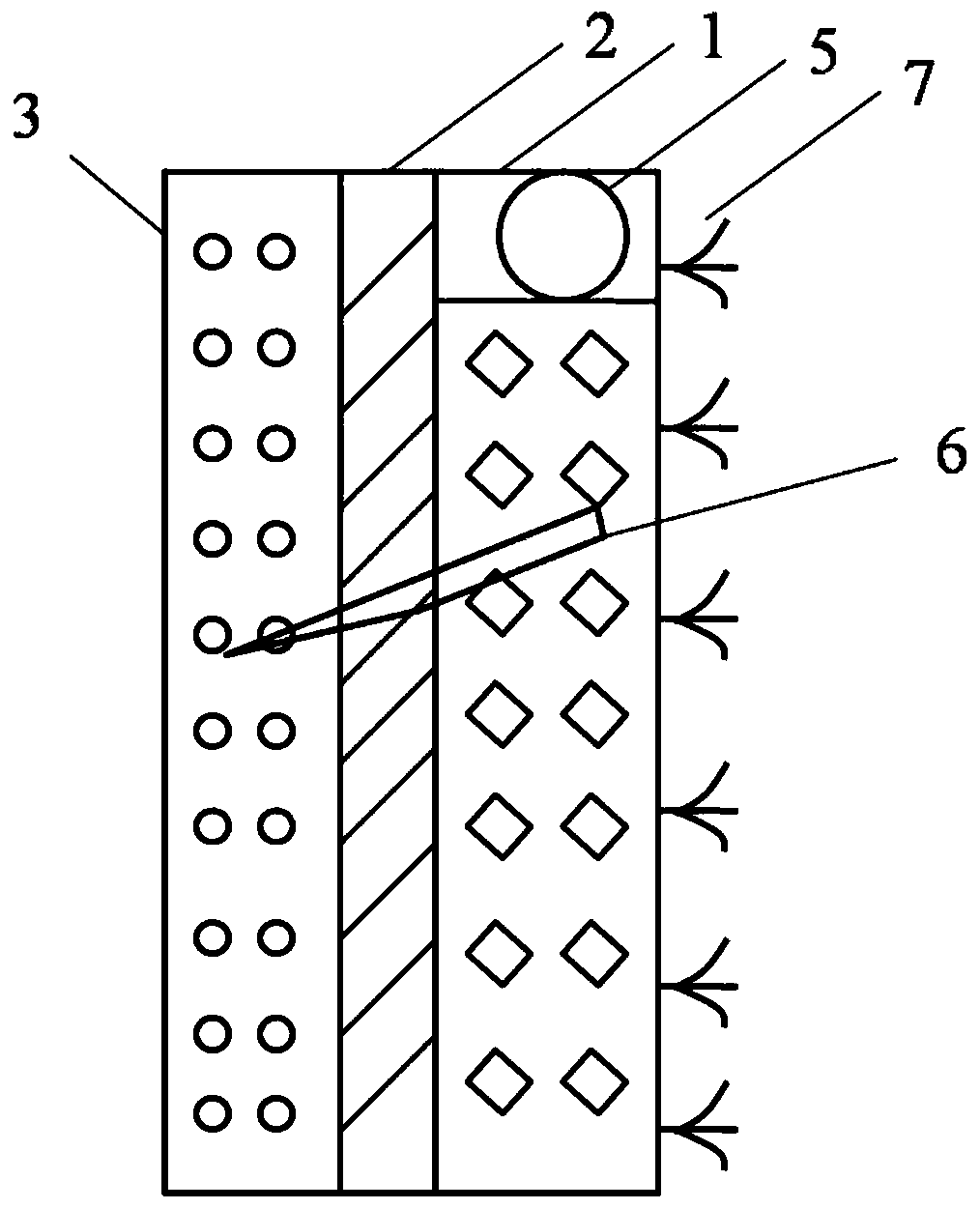

[0052] A kind of multifunctional ecological exterior wall of the present invention, the first kind of structure is as figure 1 As shown, the ceramic thermal insulation and waterproof layer 3 is directly used as the wall of a new building, including any one or two or three of the ceramic thermal insulation and waterproof layer 3, the sound-absorbing layer 1 and the water outlet assembly arranged sequentially from the inside to the outside. One, the ceramic thermal insulation and waterproof layer 3 is bonded together with the sound-absorbing layer 1 through the bonding layer 2, the green layer 7 is located on the surface of the sound-absorbing layer 1, and the upper part of the wall of the sound-absorbing layer 1 is along the width direction (direction parallel to the ground) ) leaves a gap, and a water outlet component is installed in the gap for adjusting humidity and temperature.

[0053] Among them, the ceramic thermal insulation and waterproof layer 3 of the first structure...

Embodiment 2

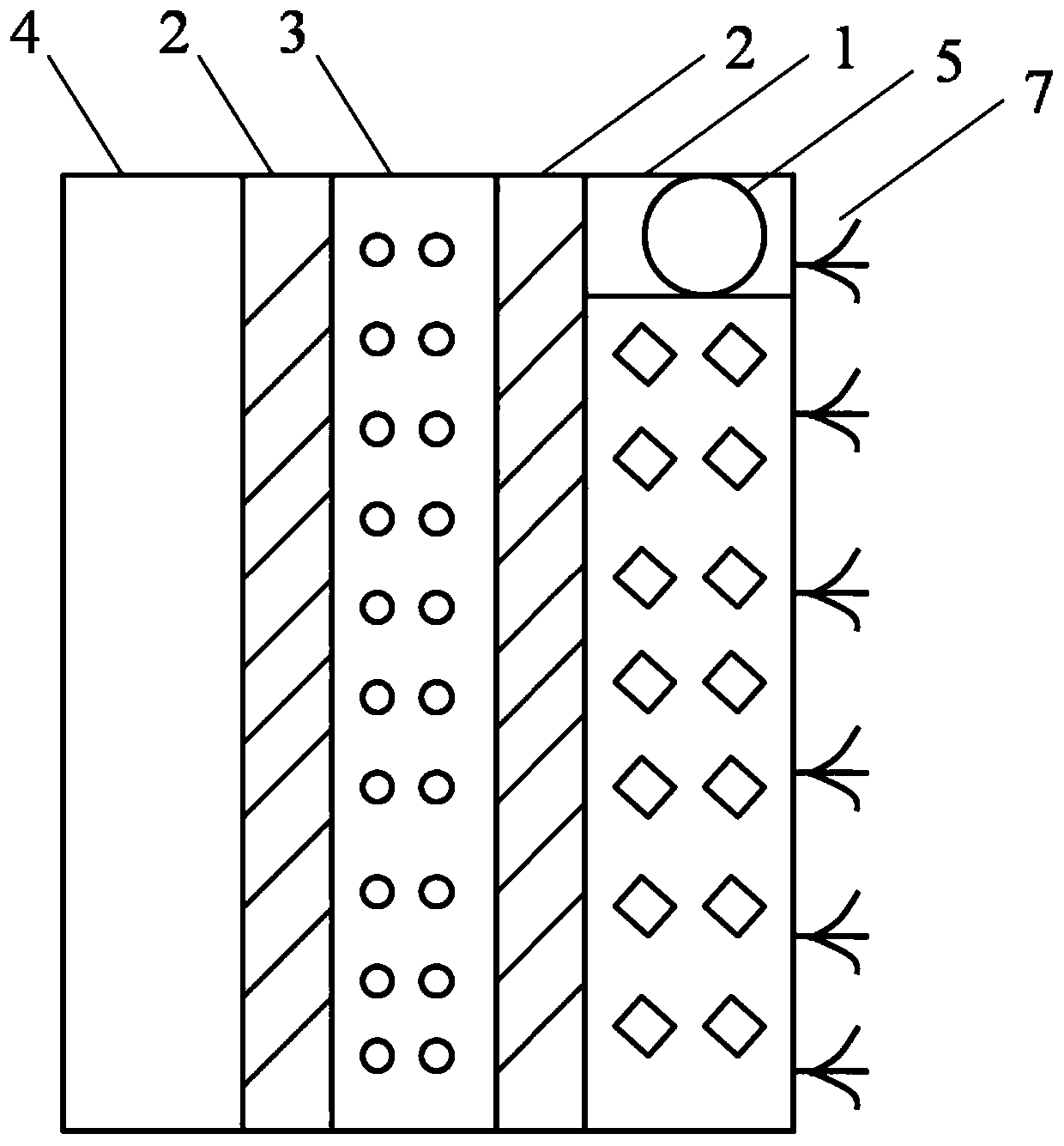

[0064] The second kind of multifunctional ecological exterior wall of the present invention is as a structure such as image 3 As shown, it also includes that the inner side of the ceramic thermal insulation and waterproof layer 3 is bonded to the surface of the cement block 4 through the bonding layer 2, and the outer side of the ceramic thermal insulation and waterproof layer 3 is bonded to the sound-absorbing layer 1 through the bonding layer 2, and the greening The first layer is located on the surface of the sound-absorbing layer 1, and the upper part of the wall of the sound-absorbing layer 1 leaves a gap along the width direction (parallel to the ground), and a water outlet component is installed in the gap for adjusting humidity and temperature.

[0065] Among them, the ceramic thermal insulation and waterproof layer 3 includes 150kg / m 3 ~300kg / m 3 The closed-cell foam ceramic board is used for thermal insulation.

[0066] The bonding layer 2 is cement slurry.

[00...

Embodiment 3

[0113] Step 1, preparing ceramic thermal insulation and waterproof board;

[0114] The specific process of step 1 is as follows:

[0115] Step 1.1, take 25% of fly ash, 15% of coal gangue, 10% of red mud, 43% of shale, 7% of feldspar, and 0.3% of composite foaming agent according to the weight percentage, and set aside;

[0116] Composite foaming agent in step 1.1 is calcium carbonate and calcium sulfate composition;

[0117] Step 1.2: Coal gangue and shale are roughly crushed into particles smaller than 3mm by a crusher, and then put into a ball mill together with fly ash, red mud, feldspar powder, composite foaming agent and water to grind them into fine powder. 200 mesh sieve;

[0118] Step 1.3, spray drying and granulating the material obtained in step 1.2;

[0119] In step 1.4, the granular material obtained by granulating in step 1.3 is loaded into a refractory mold, and sent into a kiln for firing to obtain a closed-cell foam ceramic plate;

[0120] In step 1.4, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com