Tunnel secondary lining automatic constant temperature maintenance simple bench

An automatic, tunnel technology, applied in the direction of tunnel lining, tunnel, wellbore lining, etc., can solve the problems of inconvenience, water pipe wear, labor and labor, etc., to achieve the effect of convenient use, speeding up heating treatment, and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

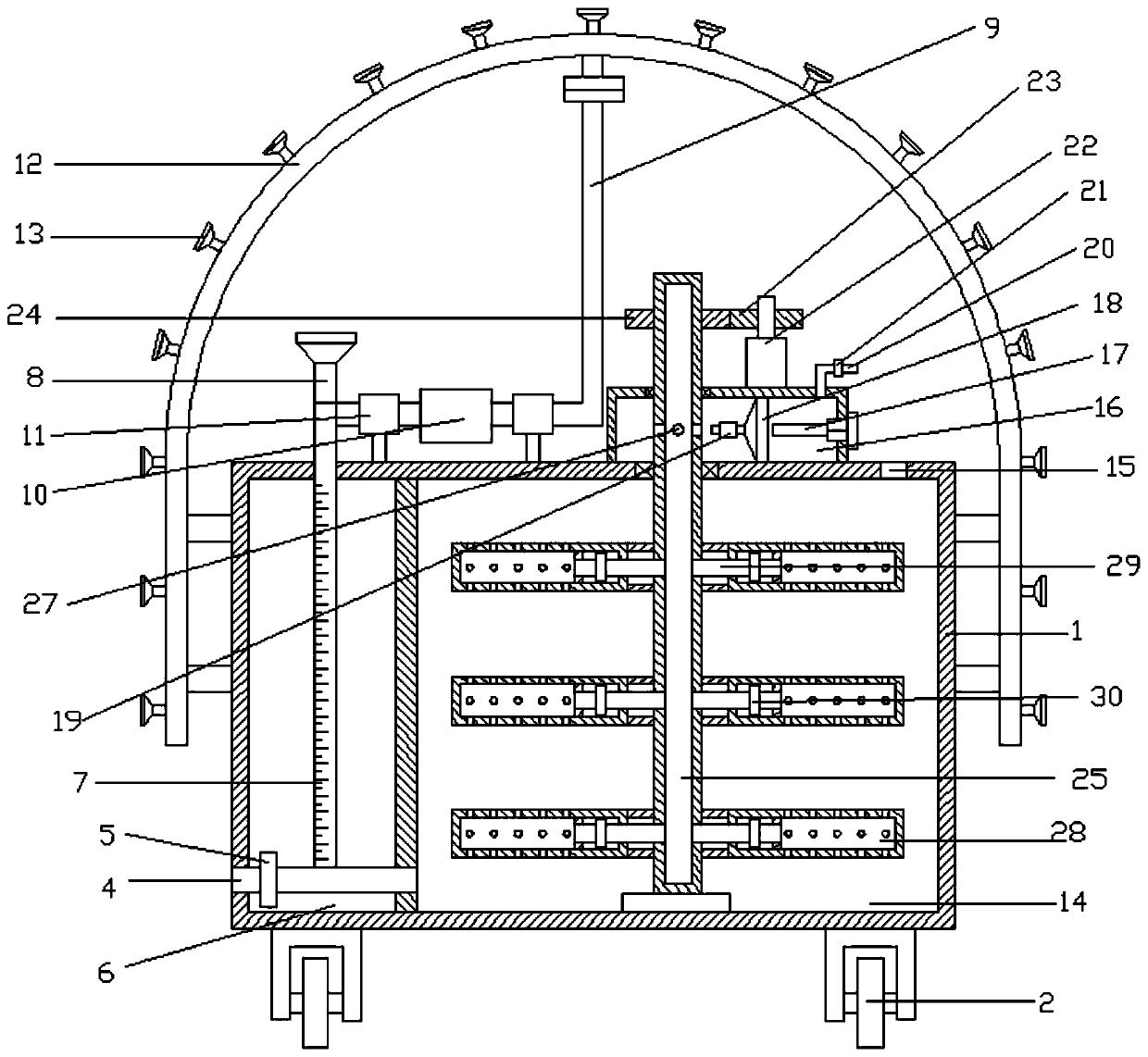

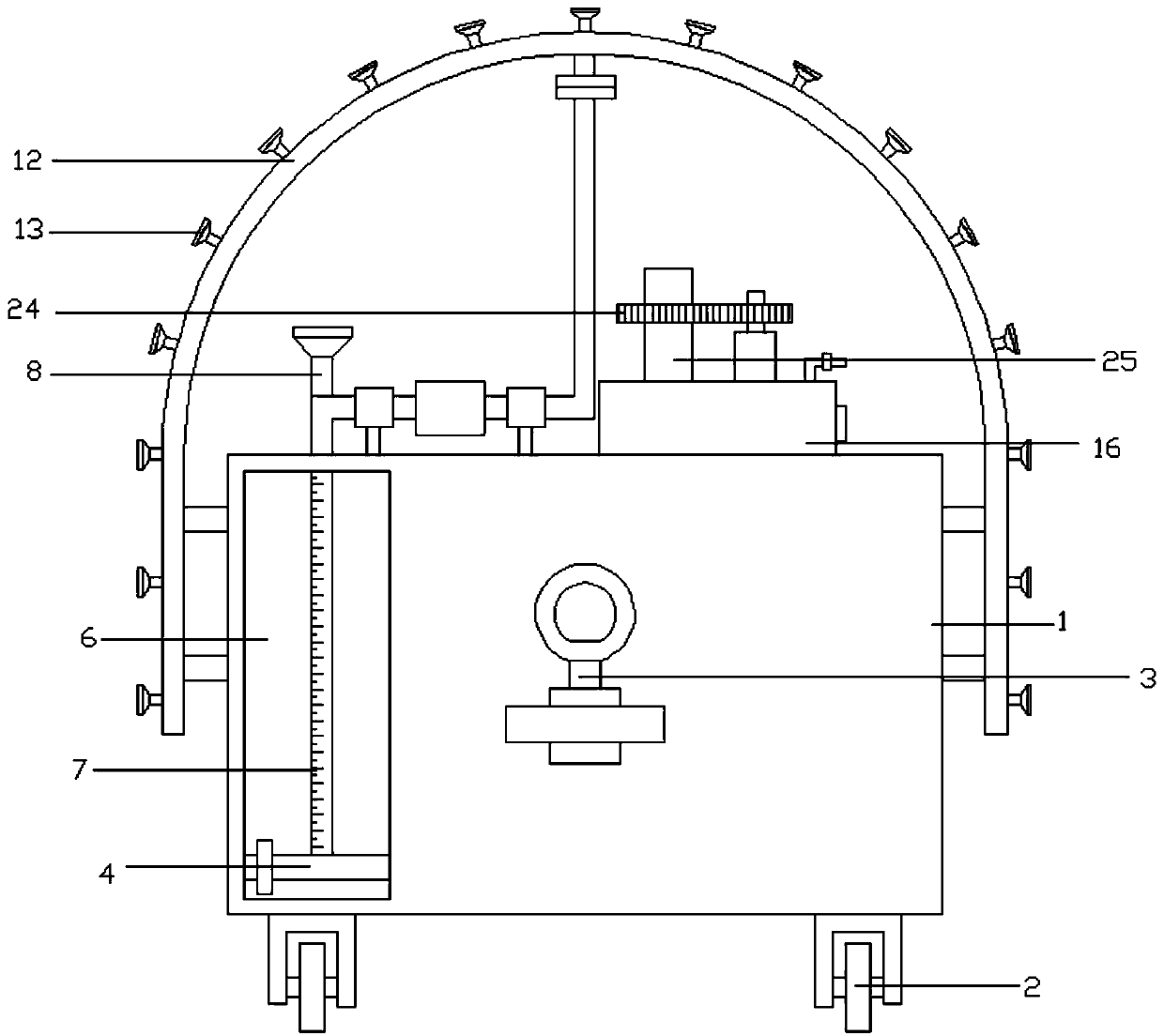

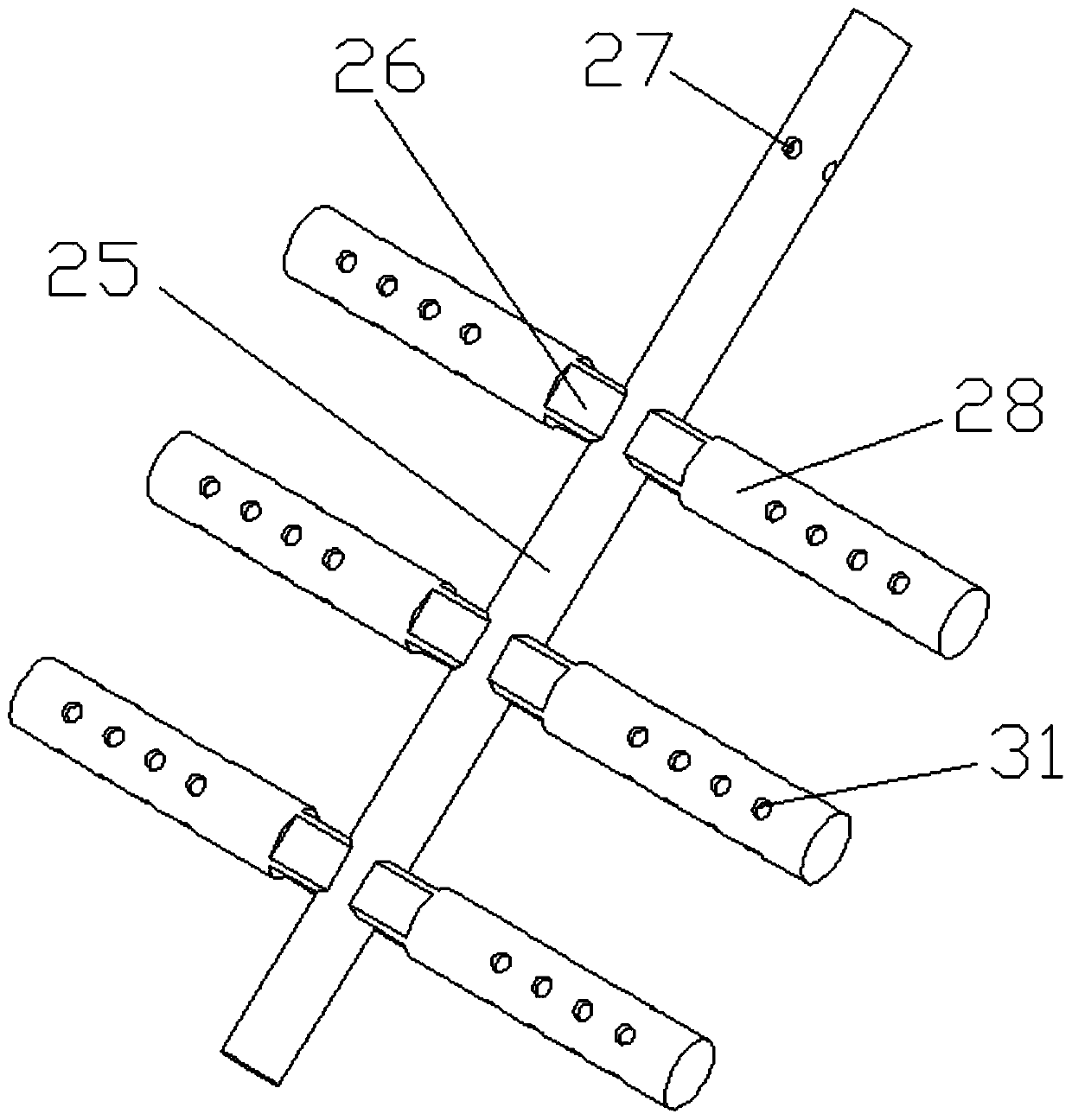

[0024] refer to Figure 1~3 , in the embodiment of the present invention, a simple platform for automatic constant temperature maintenance of the second lining of the tunnel, including a box body 1, the four corners of the lower side of the box body 1 are fixedly equipped with rollers 2, which can facilitate the movement of the equipment, and the left end of the box body 1 is provided with Groove 6, the lower end of the groove 6 is provided with an outlet pipe 4, the left end of the outlet pipe 4 is provided with a solenoid valve 5, which can control the discharge of water, and the upper side of the outlet pipe 4 is provided with a water level measuring tube 7, which can be used to detect the storage inside the equipment Water quantity, water level measuring tube 7 upper side is equipped with water adding pipe 8, can add aqueous solution conveniently, is positioned at the water level measuring tube 7 right side of box body 1 upper side and is provided with suction pipe 9, is eq...

Embodiment 2

[0027] The difference from the first embodiment is that the middle part of the front side of the box body 1 is provided with a connecting piece 3, which can be connected with the power equipment, which can facilitate the movement of the equipment and reduce manpower and material resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com