Water-rich tunnel construction pre-drainage structure and construction method

A technology for advanced drainage and water-rich tunnels, applied in drainage, earthwork drilling, safety devices, etc., can solve problems such as difficult to control water flow and affect tunnel construction progress, and achieve simple structure, avoid safety risks and property losses, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

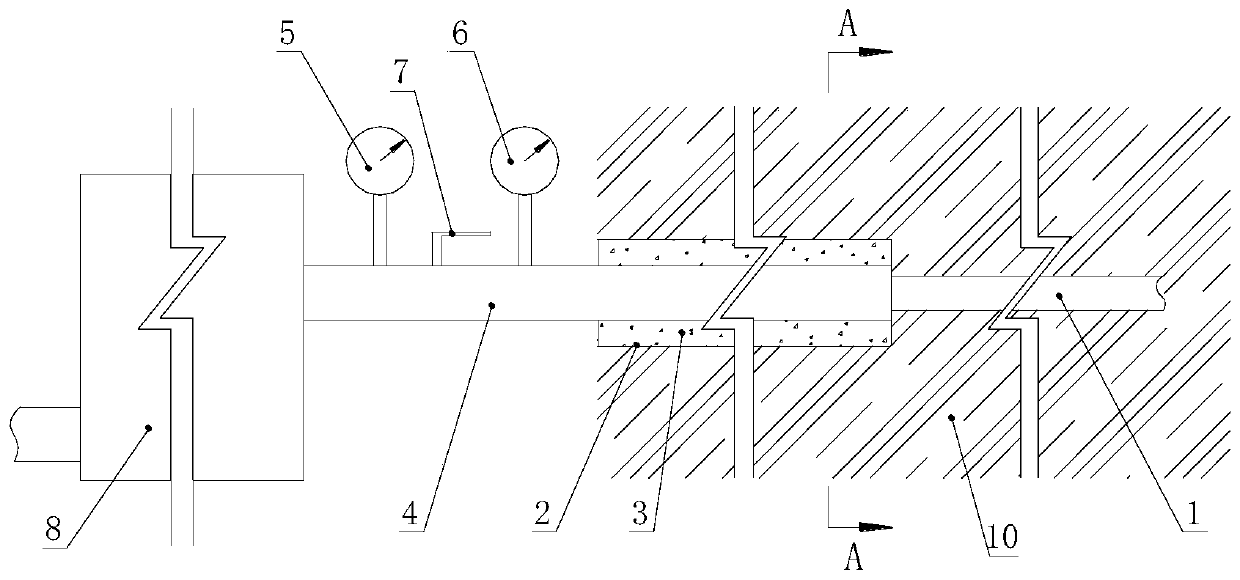

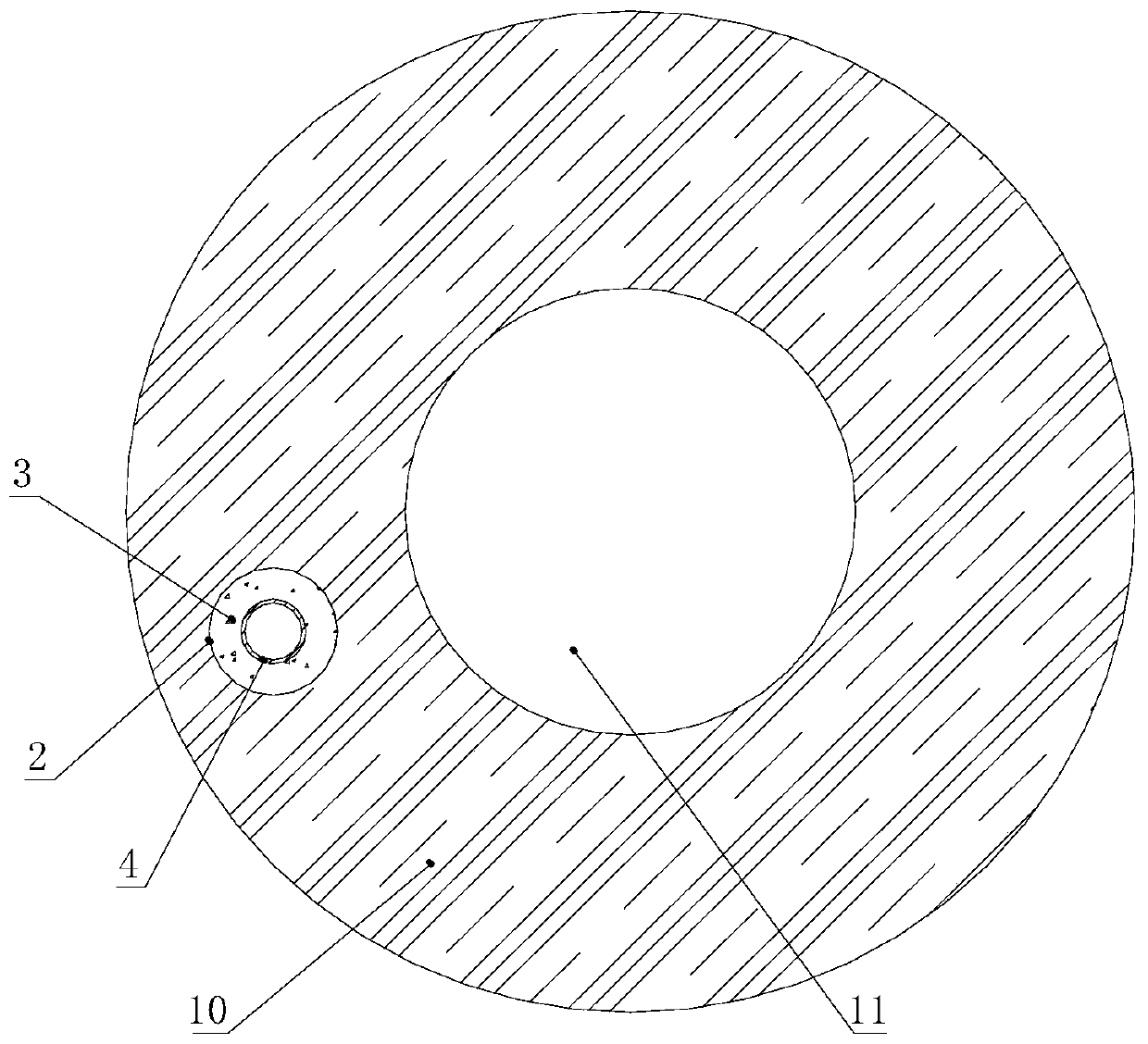

[0028] An advanced drainage structure for water-rich tunnel construction, including an advanced drainage hole 1, the advanced drainage hole 1 extends into the groundwater of the rock mass 10 along the excavation direction of the tunnel 11, and the advanced drainage hole 1 is located in the rock mass on the side of the tunnel 11 Inside. It also includes a drainage hole 2, the drainage hole 1 is located in the rock mass 10 on the side of the tunnel 11, and the drainage hole 2 communicates with the advanced drainage hole 1. The drainage hole 2 and the leading drainage hole 1 are arranged in sequence along the tunnel excavation direction, that is to say, the leading drainage hole 1 is located in front of the drainage hole 2 (with the tunnel excavation direction as the front). The inner wall of the drainage hole 2 is provided with an anti-seepage layer 3, and the drainage hole 2 is used to discharge the overflowing water from the leading drainage hole 1, so as to prevent groundwate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com