A system and method for cooperating heat supply with heat and electricity in a gas-fired thermal power plant

A technology of thermoelectric synergy and heating system, applied in the energy field, can solve the problems of unstorage, waste, insufficient power supply, etc., and achieve the effect of reducing the peak-to-valley difference of the power grid, alleviating the peak-to-valley difference, and avoiding heat waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

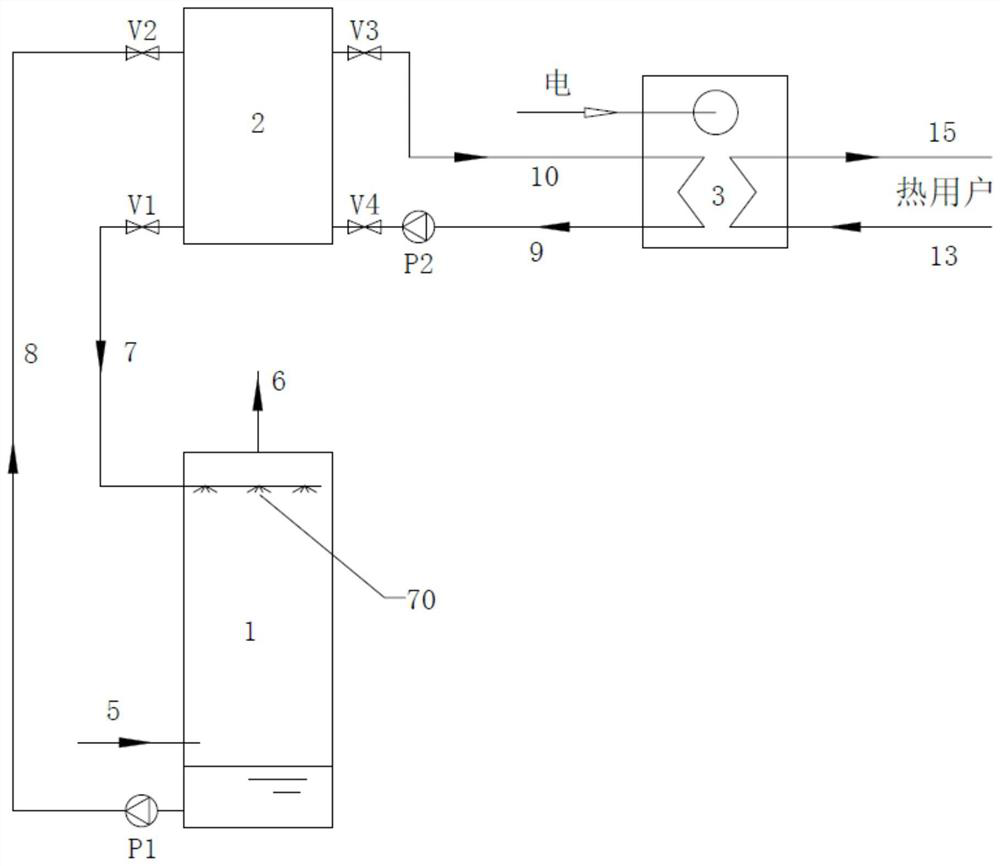

[0055] Embodiment 1 provides the most basic cogeneration heat supply system of a gas-fired thermal power plant, and its structure will be described in detail below.

[0056] refer to figure 1 , the heat-electricity collaborative heating system of the gas-fired thermal power plant includes a heat exchange energy storage system, an electric heat regulation system and a heating network heating system.

[0057] Wherein, the heat exchange energy storage system includes a heat exchanger 1, a heat storage tank 2, a first cold water supply pipe 7, a first hot water return pipe 8, a first circulation pump P1, a first valve V1 and a second valve V2,

[0058] The lower part and the top of the heat exchanger 1 are respectively provided with a flue gas inlet 5 and a flue gas outlet 6, the flue gas inlet 5 is used to communicate with the tail flue of the waste heat boiler of the gas-fired power plant, and the flue gas outlet 6 is used to discharge the inside of the heat exchanger 1 rising ...

Embodiment 2

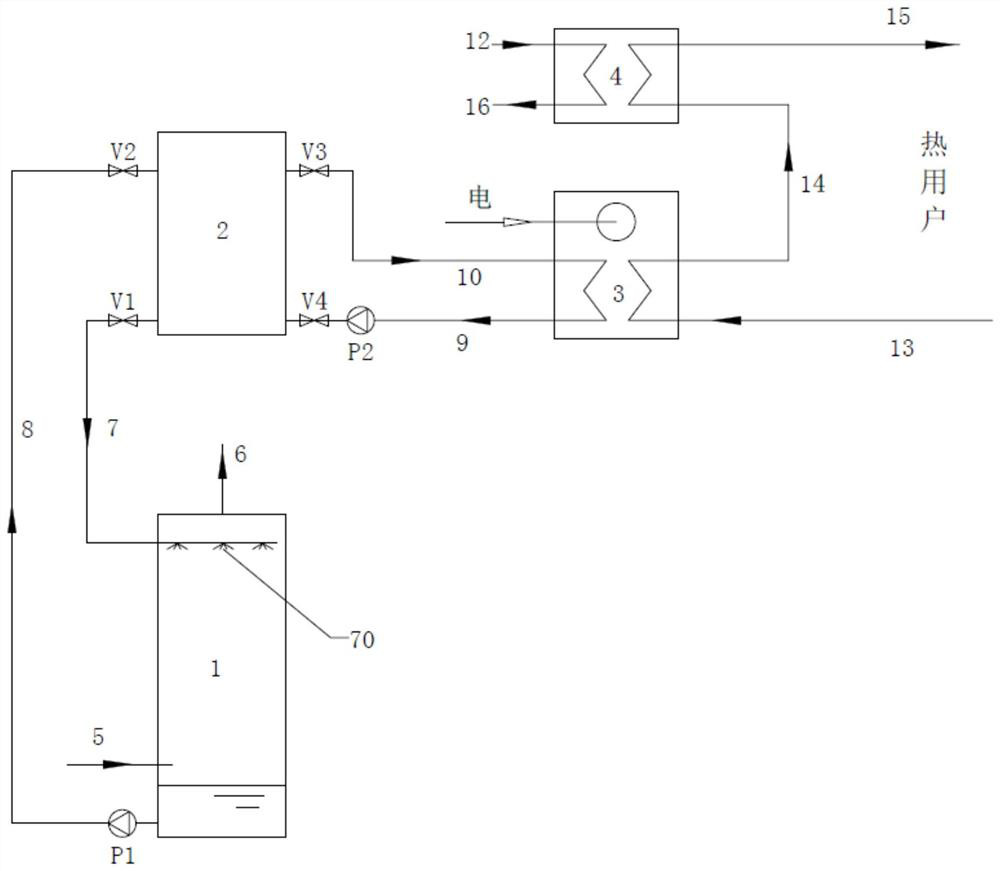

[0071] On the basis of embodiment 1, in order to further improve the heating capacity of the low-temperature return water of the heating network pipeline, embodiment 2 adds a heating network heater 4, and its connection relationship will be described in detail below.

[0072] refer to figure 2 , the cascade heating device also includes a heat network heater 4, and the heat network heater 4 is an existing mature technology, which is divided into various forms such as a steam-water heat exchanger or a water-water heat exchanger, and the preferred shell in embodiment 2 Tubular steam-water heat exchanger, the shell-and-tube steam-water heat exchanger includes steam inlet, condensate outlet, steam side exhaust pipe, heated water outlet, heated water inlet and water side exhaust pipe, etc.

[0073] As a specific implementation, the heating side of the heating network heater 4 is provided with a steam inlet and a condensate outlet, and the heated side of the heating network heater 4...

Embodiment 3

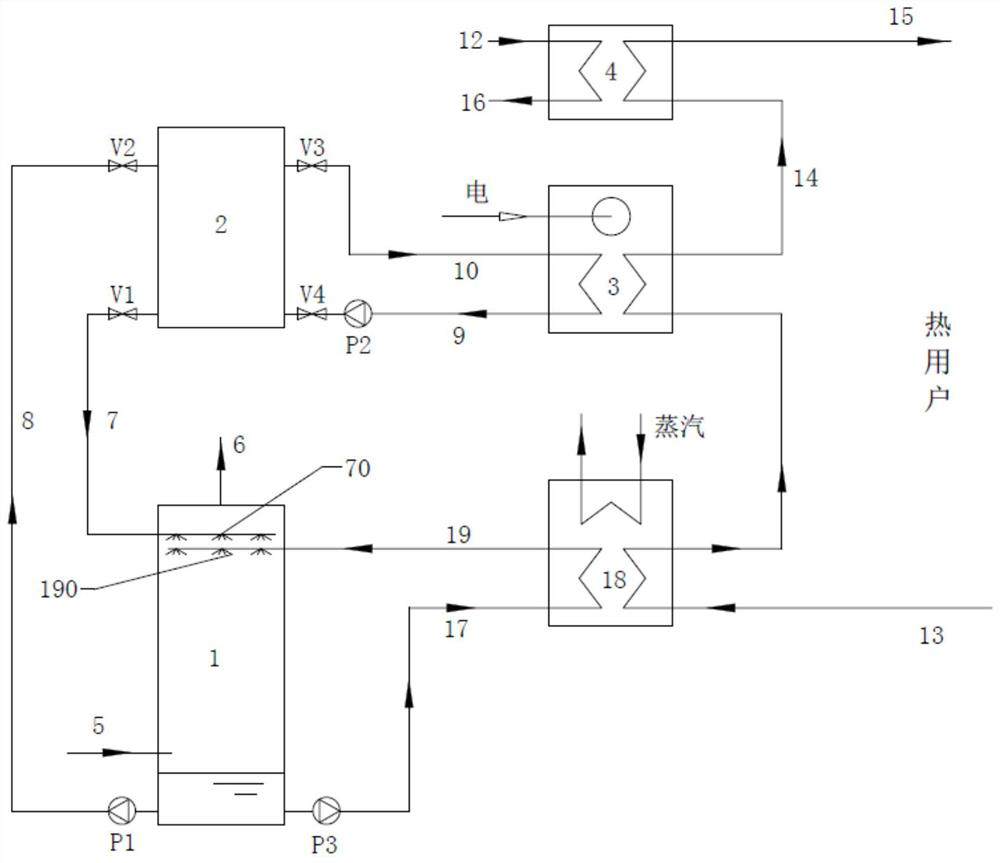

[0078] On the basis of Example 2, in order to improve the heat exchange efficiency of the flue gas in the heat exchanger 1 and improve the heating capacity of the low-temperature return water in the heating network pipeline, a spray circulation system and an absorption heat pump 18 are added in Example 3, as follows Describe its connection relationship in detail.

[0079] refer to image 3 , the cascade heating device also includes an absorption heat pump 18, which includes an evaporator, a condenser, an absorber, and a generator, etc., wherein the heat network return cold water pipe 13 can be connected with the absorption heat pump 18 absorber, and It can be connected with the condenser, and the outlet of the absorber or the condenser of the absorption heat pump 18 is connected with the inlet of the condenser of the electric heat pump 3 . Specifically, the cooling water return pipe 13 of the heat network is connected with the absorber inlet of the absorption heat pump 18, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com