Strain weighing device, unmanned vending cabinet and using method thereof

A weighing device and vending container technology, applied in weighing devices, measuring devices, weighing and other directions using elastically deformable parts, can solve problems such as affecting shopping efficiency, inability to automatically settle, and no automatic detection of goods, etc., to achieve adaptation Wide range of fields, improve shopping efficiency, and enhance the effect of shopping experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

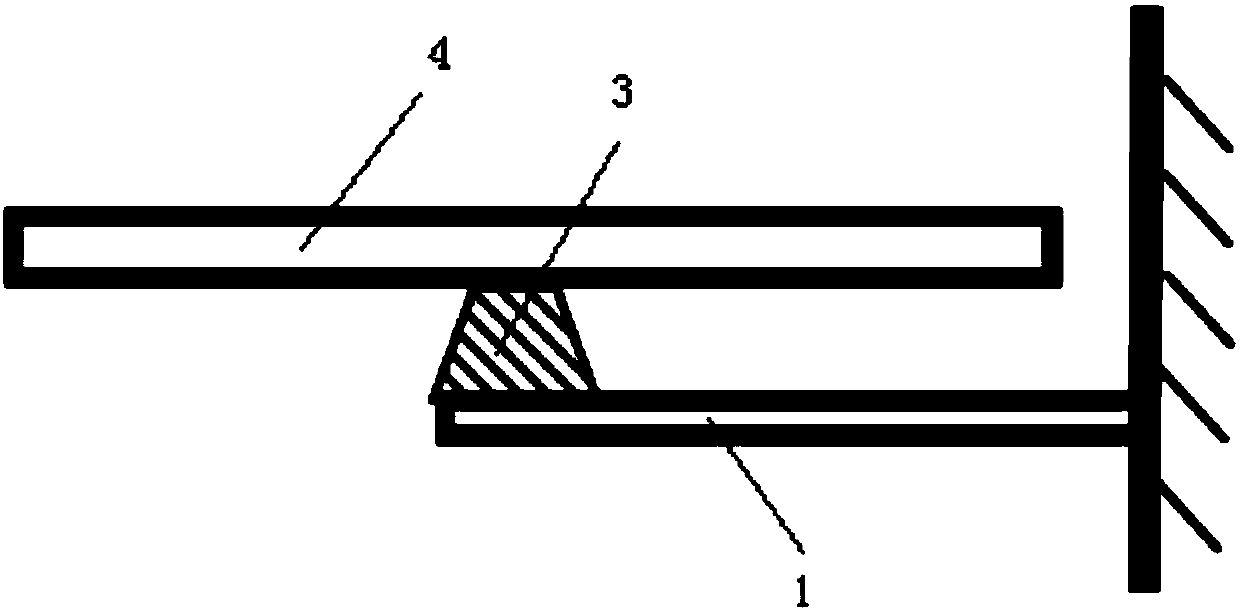

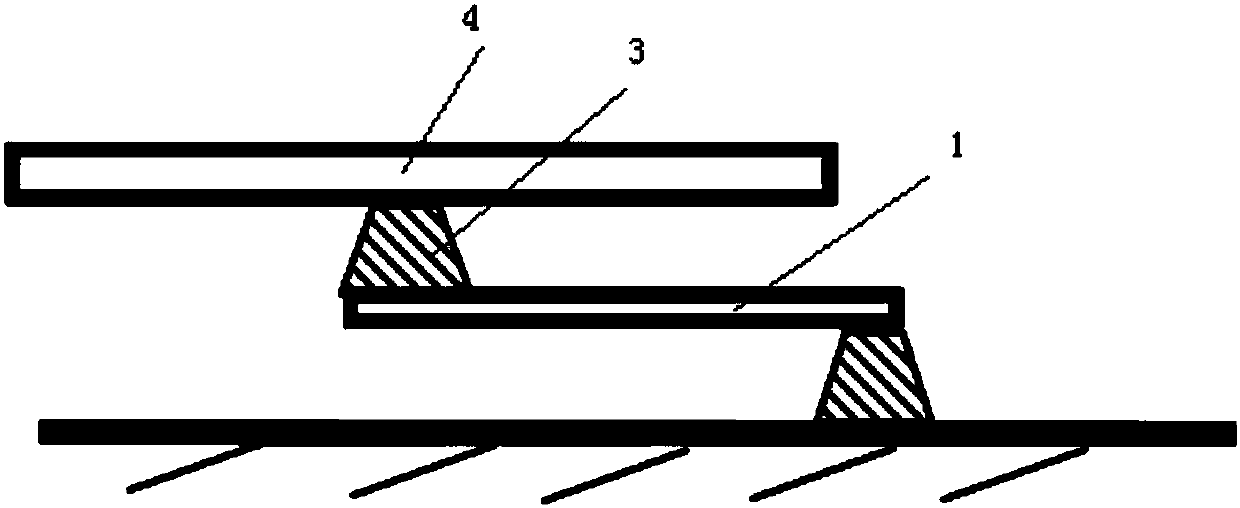

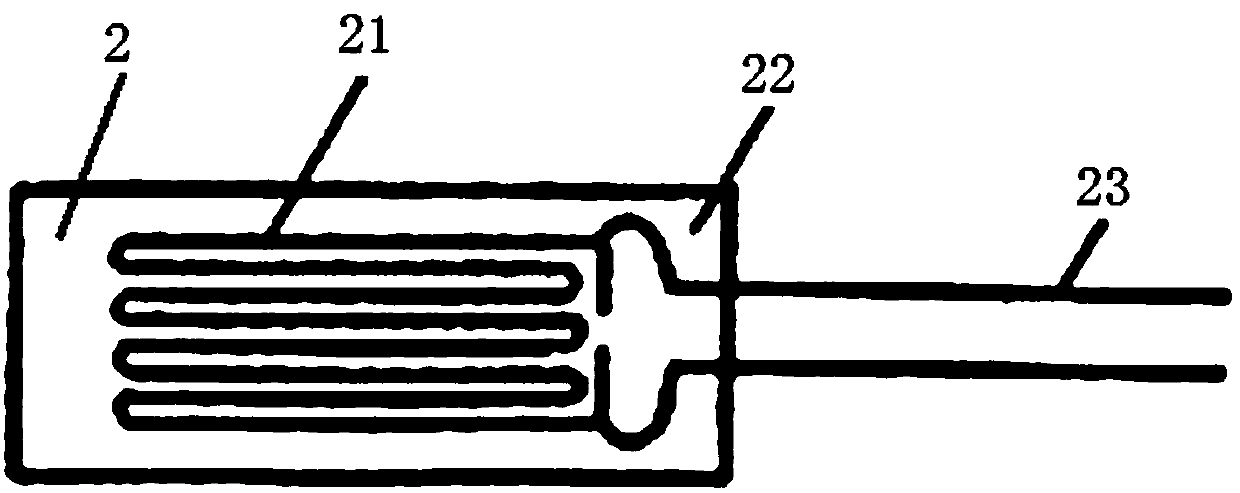

[0040] Such as figure 1 Or shown in 2, a kind of strain weighing device of the present invention comprises cantilever arm 1, and the resistance strain gauge set that is used for strain measurement is arranged on the cantilever arm 1, in order to improve strain sensitivity, resistance strain gauge set includes four resistance strain gauges 2, such as image 3 As shown, the resistance strain gauge 2 includes a wire grid 21 wound in an S shape by constantan wire or nickel-chromium wire with a diameter of 0.02-0.05 mm, or a grid structure is corroded with a very thin metal foil, and the wire grid or grid The shape structure is sandwiched between two layers of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com