Whole-wheat bread flour and preparation method thereof

A technology of whole-wheat bread flour and bread flour, which is applied in dough processing, baking, baked food, etc., can solve the problems of food safety and short shelf life of whole-wheat bread flour, and achieve good product quality, better flavor, and reduced risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

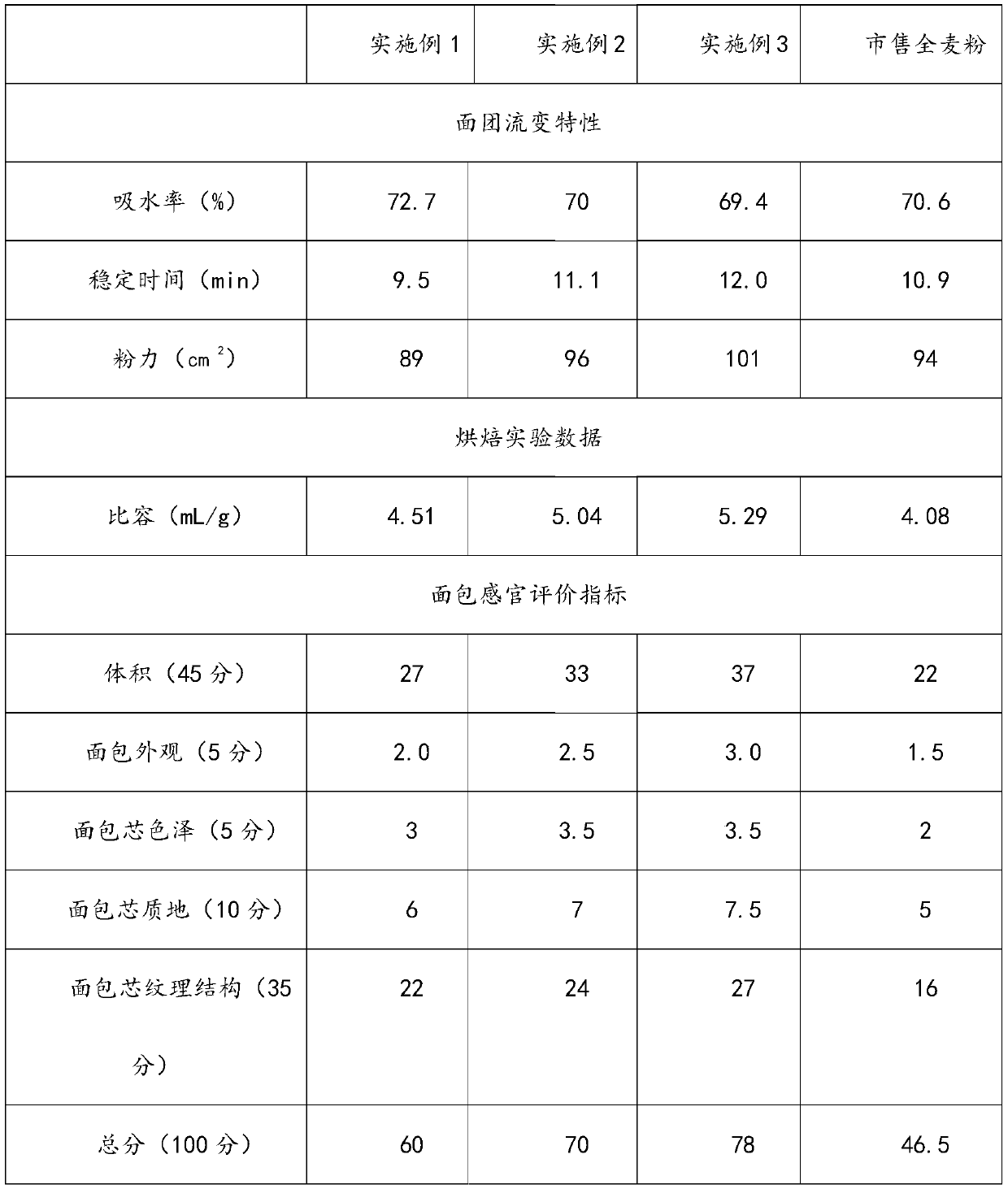

Examples

Embodiment 1

[0023] A whole wheat bread flour is prepared from the following raw materials in parts by weight: 75 parts of bread flour with a wet gluten content of 36%, and 25 parts of baked and cooled bran. Specifically, the whole wheat bread flour product is obtained by uniformly mixing the bread flour and the bran.

[0024] Wherein, the bread flour is processed from wheat raw materials with a hardness index of 70-85 and a crude protein content of 13-16%; the wheat raw materials include 54 parts by weight of CWRS, 14 parts of APH, and 6 parts of DNS , 26 servings of domestic wheat.

[0025] The bran is prepared from a large piece of bran material with an average particle size of 2-5mm after being ground and sifted by the Zhonglu skin mill; specifically, the bran material is put into an oven for baking, and the temperature of the oven is 140-160 ℃, the lower heat temperature is 140-160 ℃, bake for 10-20 minutes, and rotate the baking tray every 5 minutes; cool down after baking to obtain...

Embodiment 2

[0027] The whole wheat bread flour is prepared from the following raw materials in parts by weight: 80 parts of bread flour with a wet gluten content of 36%, and 20 parts of baked and cooled bran. Specifically, the whole wheat bread flour product is obtained by uniformly mixing the bread flour and the bran.

[0028] Wherein, the bread flour is processed from wheat raw materials with a hardness index of 70-85 and a crude protein content of 13-16%; the wheat raw materials include 45 parts by weight of CWRS, 15 parts of APH, and 15 parts of DNS , 25 servings of domestic wheat.

[0029] The bran is prepared from a large piece of bran material with an average particle size of 2-5mm after being ground and sifted by the Zhonglu skin mill; specifically, the bran material is put into an oven for baking, and the temperature of the oven is 140-160 ℃, the lower heat temperature is 140-160 ℃, bake for 10-20 minutes, and rotate the baking tray every 5 minutes; cool down after baking to obt...

Embodiment 3

[0031] A whole wheat bread flour is prepared from the following raw materials in parts by weight: 85 parts of bread flour with a wet gluten content of 36%, and 15 parts of baked and cooled bran. Specifically, the whole wheat bread flour product is obtained by uniformly mixing the bread flour and the bran.

[0032] Wherein, the bread flour is processed from wheat raw materials with a hardness index of 70-85 and a crude protein content of 13-16%; the wheat raw materials include 50 parts by weight of CWRS, 12 parts of APH, and 10 parts of DNS , 28 servings of domestic wheat.

[0033] The bran is prepared from a large piece of bran material with an average particle size of 2-5 mm after being ground and sieved by the Zhonglu skin mill; specifically, the bran material is put into an oven and baked together, and the temperature of the oven is 140-160 ℃, the lower heat temperature is 140-160 ℃, bake for 10-20 minutes, and rotate the baking tray every 5 minutes; cool down after baking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com