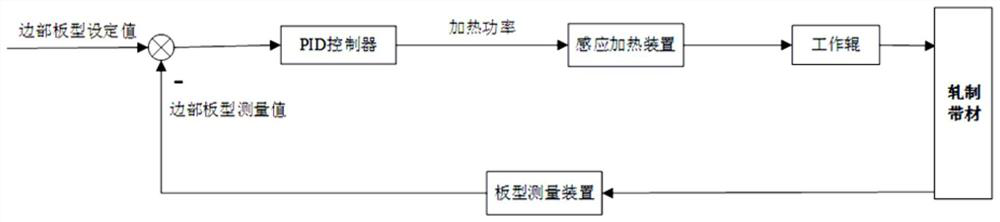

A strip edge profile control method and system based on induction heating

A technology of plate shape control and induction heating, applied in contour control, manufacturing tools, metal rolling, etc., can solve problems such as difficulty in obtaining satisfactory controller parameters, inability to realize automatic adjustment, difficulty in maintaining stability, etc., and achieve short debugging time , improved plate shape, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

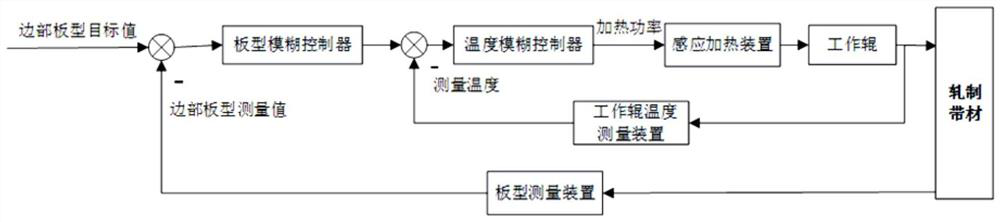

[0042] The application will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the application and implement it, but the examples given are not intended to limit the application.

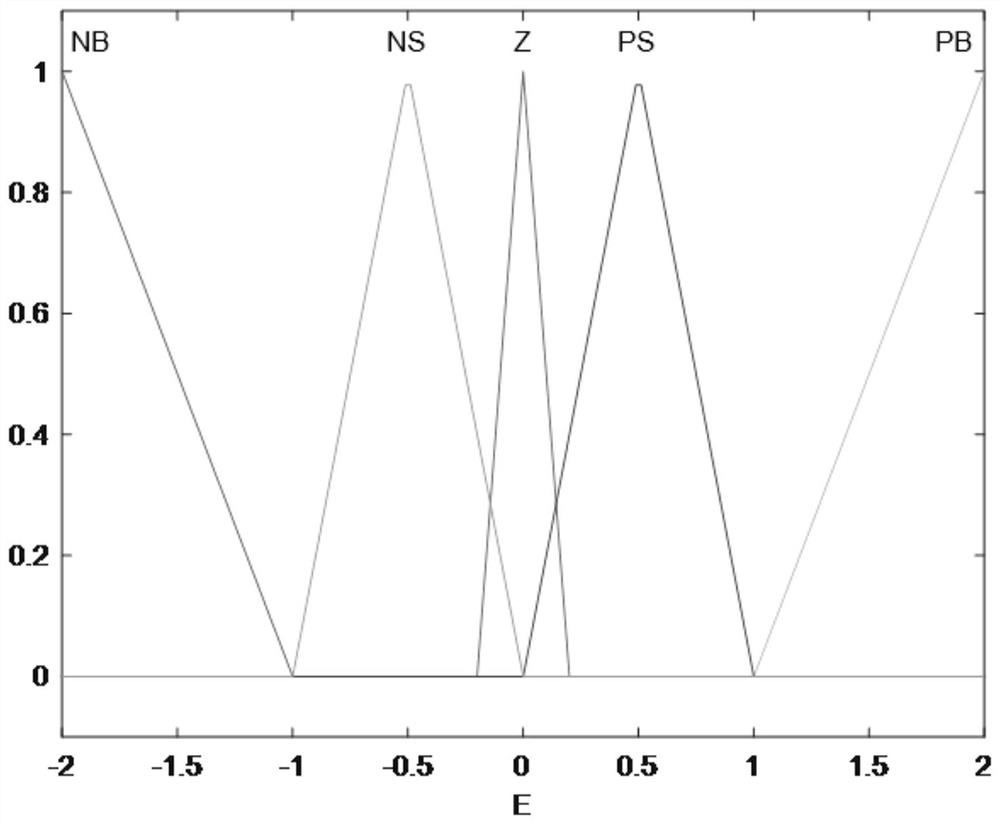

[0043] Such as figure 2 As shown, the application provides a method for controlling the shape of a strip edge based on induction heating, wherein the control method includes the following steps,

[0044] (1) The target value of the edge plate shape is compared with the measured value of the edge plate shape to obtain the target temperature value. Step (1) is specifically,

[0045] (1.1) Set the plate shape target value at the edge of the strip;

[0046] (1.2) Obtain the actual strip edge profile measurement value from the profile measuring device;

[0047] (1.3) compare the plate shape target value with the plate shape measurement value to obtain the plate shape deviation value;

[0048] (1.4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com