PCB drilling device

A PCB board and drilling device technology, applied in the field of circuit boards, can solve the problems of increasing the unevenness of the hole wall, affecting the electroplating process, breaking, etc., and achieve the effects of reducing temperature, avoiding knife sticking and chip removal difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

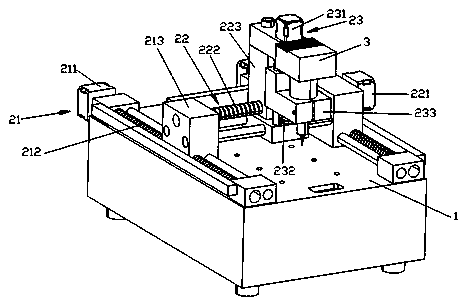

[0024] see Figure 1-2 As shown, the embodiment of the present invention discloses a PCB board drilling device, comprising:

[0025] Workbench 1;

[0026] A three-axis motion mechanism 2, which is arranged on the workbench 1;

[0027] Drilling module 3, which is connected with the three-axis motion mechanism 2;

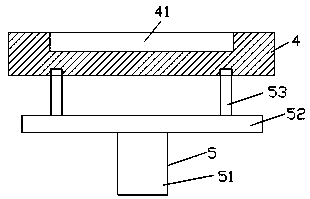

[0028] PCB board carrying jig 4, which is located on the workbench 1 and below the drilling module 3;

[0029] A blowing mechanism (not shown in the figure), the blowing mechanism is used to cool down the PCB when the drilling module 3 is drilling;

[0030] A control unit is electrically connected to the three-axis motion mechanism 2, the drilling module 3 and the blowing mechanism respectively.

[0031] As one of the preferred solutions of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com