High-temperature superconducting maglev structure and high-temperature superconducting strip maglev train

A technology of high-temperature superconducting strips and maglev trains, applied in the field of maglev, can solve problems such as poor decoupling and insufficient stability of the integrated rigid suspension frame, and achieve high stability and decoupling, high engineering application value, and stable drive Effects on Efficiency and Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

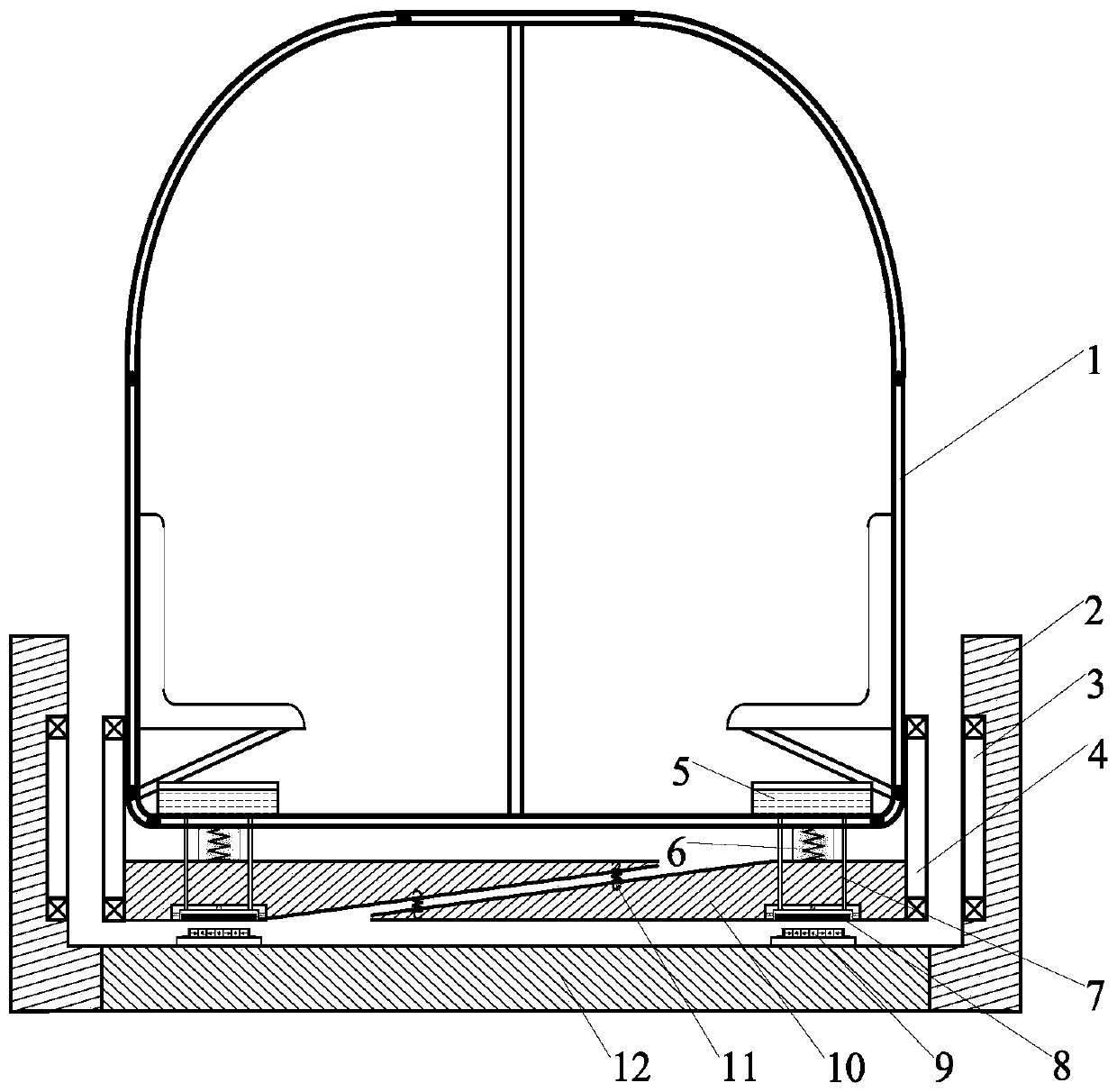

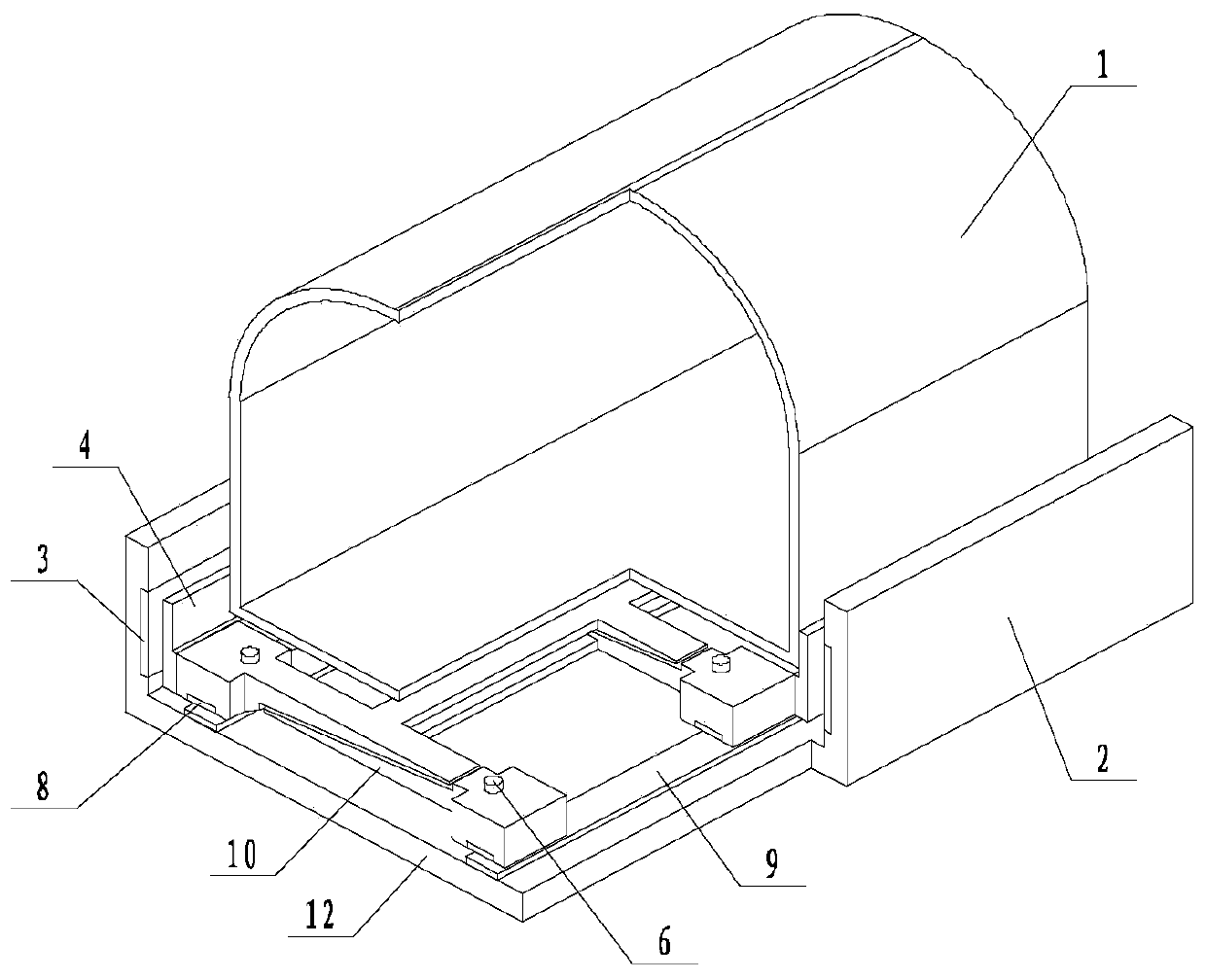

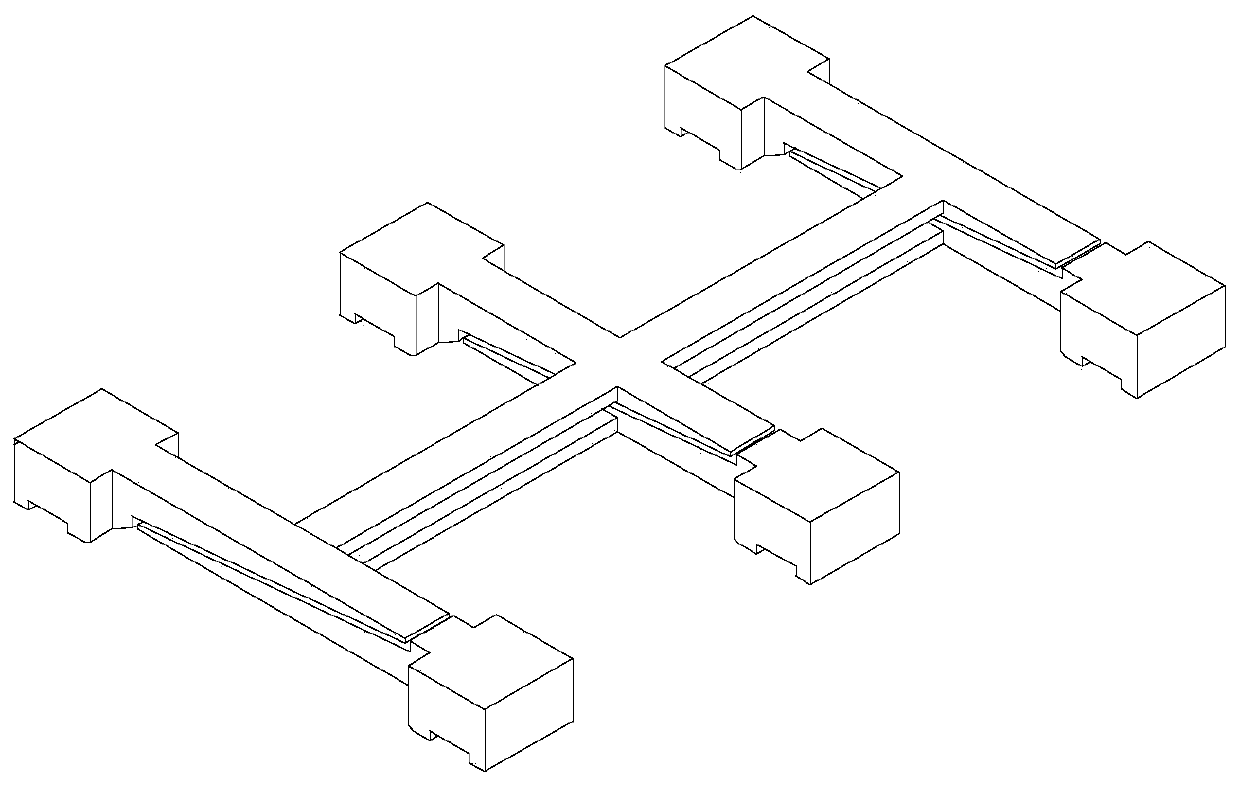

[0056] The high-temperature superconducting magnetic levitation structure includes a permanent magnet track 9 and a levitation frame 10 located above the permanent magnet track 9. The bottom of the levitation frame 10 is provided with a levitation dewar 8 facing the permanent magnet track 9. The levitation frame 10 It includes two wedge blocks with opposite inclined surfaces, and the inclined surfaces of the two wedge blocks are connected by a plurality of elastic members 11. The elastic member 11 in this embodiment is preferably a tension spring, and the suspension frame is composed of two wedge-shaped blocks on the left and right, which are coupled by two tension springs, which has higher stability and decoupling than a rigid connection.

Embodiment 2

[0058] On the basis of Embodiment 1, the permanent magnet track 9 is a halbach array track with a cross-sectional structure consisting of four horizontally magnetized magnets and three vertically magnetized magnets alternately arranged. The floating Dewar 8 is provided with a superconducting material composed of a plurality of superconducting unit arrays, and the superconducting unit includes a curved stacking unit formed by stacking a plurality of layers of high temperature superconducting tapes along a curved surface. The curved surface is a circular arc surface with a concave surface facing down. A number of curved stacking units are arranged side by side to form a curved stacking group; it also includes a vertical stacking group formed by a number of vertical stacking units side by side, the vertical stacking unit is formed by stacking a plurality of layers of vertically distributed high temperature superconducting tapes The superconducting material is formed by alternating...

Embodiment 3

[0060] In order to overcome the shortcomings of the existing YBCO high-temperature superconducting block maglev train system (limited load and guiding capacity, unstable motor air gap, low structural strength of the suspended dewar, YBCO block material is easy to deteriorate and chip, etc.), the design such as figure 1 , Figure 2a The high-temperature superconducting strip maglev train shown, combined with finite element simulation and actual production and processing experience, carries out technical development and performance optimization on core modules such as permanent magnet track, levitation dewar, and ReBCO high-temperature superconducting strip maglev system. In order to form the ReBCO high-temperature superconducting strip maglev train technology that can replace the YBCO high-temperature superconducting block maglev train, thus breaking the foreign monopoly of YBCO high-temperature superconducting block and floating Dewar technology.

[0061] In this embodiment, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com