Industrial preparation method of high-purity tris(2-butoxyethyl)phosphate

A high-purity, phosphate ester technology, applied in chemical instruments and methods, phosphorus organic compounds, compounds of group 5/15 elements of the periodic table, etc., can solve the problems of product purity yield decline, low purity, serious pollution, etc. , to achieve the effect of increased yield, simple method and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

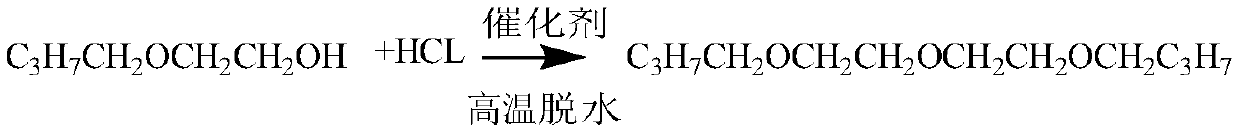

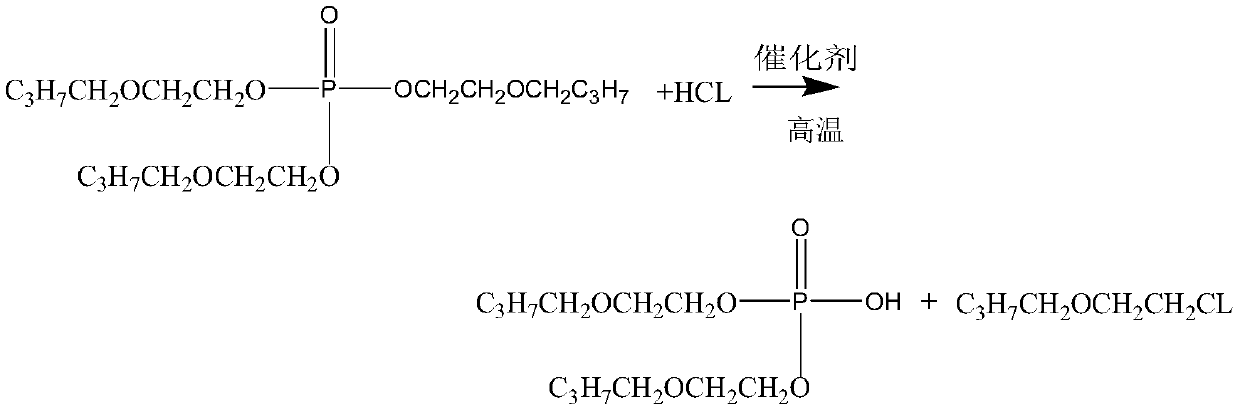

Method used

Image

Examples

Embodiment 1

[0048] 1. Pump 1540kg (13.03 kilomoles) of ethylene glycol monobutyl ether into the reactor, put 1Kg of catalyst magnesium chloride into the reactor, cool down to 20-25°C, turn on the vacuum, and add dropwise at a vacuum degree of 2-4KPa Phosphorus oxychloride 400kg (2.61 kilomoles, the molar ratio of phosphorus oxychloride to ethylene glycol monobutyl ether is 1:5), add dropwise in 3-5 hours, and slowly heat up to 50-80°C after dropping, Insulation reaction for 5 hours;

[0049] 2. After the gas phase detection reaction is complete, switch the vacuum (vacuum degree is 2 ~ 4KPa) to distill ethylene glycol monobutyl ether under reduced pressure. 10%) content is 6.5%, stop distillation;

[0050] Described gas-phase detection (the gas-phase detection method involved in the embodiment of the present invention or comparative example all adopts following method) step is specifically:

[0051] Gas phase analysis method: Injection temperature: 200°C, detector: 220°C Column temperature...

Embodiment 2

[0057] It is basically the same as Example 1, the molar ratio of phosphorus oxychloride: ethylene glycol monobutyl ether: 1:5, and the others remain unchanged. The product yield is 97.5%.

Embodiment 3

[0059] It is basically the same as in Example 1, the catalyst is changed to titanium tetrachloride, and the others remain unchanged. The product yield is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com