Patents

Literature

101 results about "2-Butoxyethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Butoxyethanol is an organic compound with the chemical formula BuOC₂H₄OH (Bu = CH₃CH₂CH₂CH₂). This colorless liquid has a sweet, ether-like odor, as it derives from the family of glycol ethers, and is a butyl ether of ethylene glycol. As a relatively nonvolatile, inexpensive solvent of low toxicity, it is used in many domestic and industrial products because of its properties as a surfactant.

Osmanthus-fragrans-fragrance tipping paper and production method thereof

InactiveCN103741554AImprove toughnessIncrease softnessSpecial paperPaper/cardboardCross-linkPolyvinyl alcohol

Disclosed osmanthus-fragrans-fragrance tipping paper is prepared from the following raw materials in parts by weight: 100-120 parts of softwood pulp, 60-70 parts of softwood pulp, 2-4 parts of ethanol, 2-3 parts of ascorbic acid, 3-5 parts of guar gum, 1-2 parts of dibutyl phthalate, 2-3 parts of polyvinyl alcohol, 1-2 parts of 2-butoxyethanol, 1-2 parts of osmanthus fragrans essential oil, 1-2 parts of hydrogen peroxide, 1-2 parts of ferrous sulphate, 3-4 parts of acrylic acid, 1-2 parts of sodium persulfate, 2-3 parts of a cross-linking agent TAC and 1-2 parts of grape seed oil. By adding osmanthus fragrans essential oil into the raw materials, osmanthus fragrans fragrance is added into the tipping paper, and also the health-care function of osmanthus fragrans is added into the tipping paper; and also, by adding ester materials into the raw materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

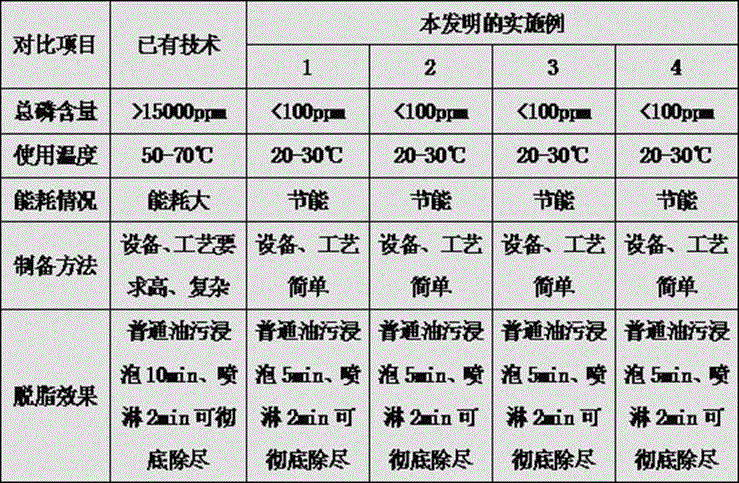

Normal-temperature nonphosphorus degreasing agent for metal surface processing and preparation method thereof

The invention discloses a normal-temperature nonphosphorus degreasing agent for metal surface processing and a preparation method thereof. The normal-temperature nonphosphorus degreasing agent comprises the raw material percentages by weight: 10-20% of sodium hydroxide, 5-10% of sodium metasilicate, 3-5% of sodium carbonate, 6-8% of alkylphenol polyoxyethylene, 2-4% of linear alkyl benzene sulphonate, 1-2% of 2-butoxyethanol, 0.5-1% of polyether and the balance of water. Compared with the prior art, the normal-temperature nonphosphorus degreasing agent has the characteristics of normal temperature, environmental protection (non phosphorus), high efficiency, safety, low foam, solubilization, good decontaminability and the like, and does not corrode steel plates, aluminum, copper, plastics, rubber and the like.

Owner:合肥华清高科表面技术股份有限公司

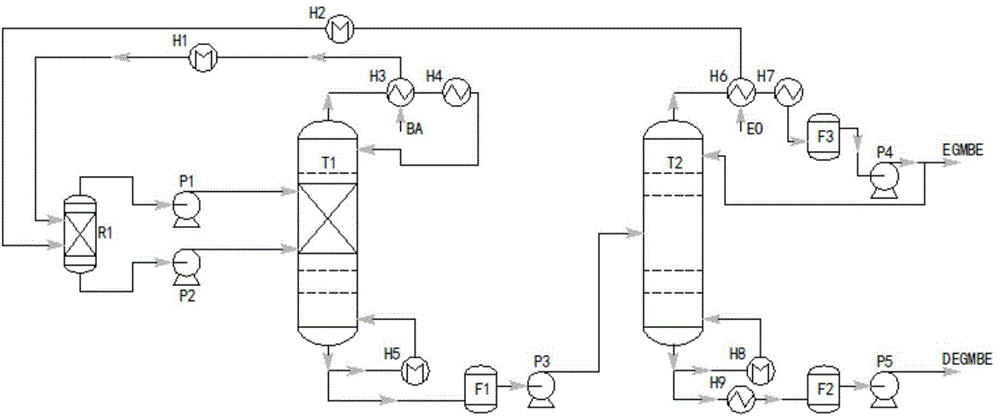

Device and processing method for synthesis of ethylene glycol monobutyl ether through reactive distillation

ActiveCN104788294AEther separation/purificationChemical industryDiethylene glycol monobutyl etherReboiler

The invention provides a device and technological process for synthesis of ethylene glycol monobutyl ether through reactive distillation. The device comprises a reactor, a reactive distillation tower, a treating tower, a condenser, a reboiler, a heat exchanger, a return tank, a kettle outlet tank, a pump and a pipeline. In the technological process, the reactive distillation tower is combined with the reactor and the treating tower. Acidic cation exchange resin or alkali anion exchanger is selected for being used as a catalyst. Preheated ethylene oxide and butanol enter into a reactor for reaction, and unreacted materials pumped into the reactive distillation tower react or are rectified on a tower plate or a filling material on the section; materials flowing down after passing through the reaction section are rectified through a stripping section; total reflux is conducted at the tower top of the reactive distillation tower; materials discharged from the tower kettle of the reactive distillation tower are pressurized to enter into the treating tower for rectification; the ethylene glycol monobutyl ether with the purity higher than 99.9 percent is obtained from the tower top of the treating tower, the yield is greater than 97 percent, and the diethylene glycol monobutyl ether is obtained from the tower kettle of the rectification tower. The device solves the problems that ethylene glycol monobutyl ether produced intermittently is not stable in product quality, the yield is relatively low, the loss of the catalyst is high, and sewage treatment is difficult.

Owner:TIANJIN PULAI CHEM TECH

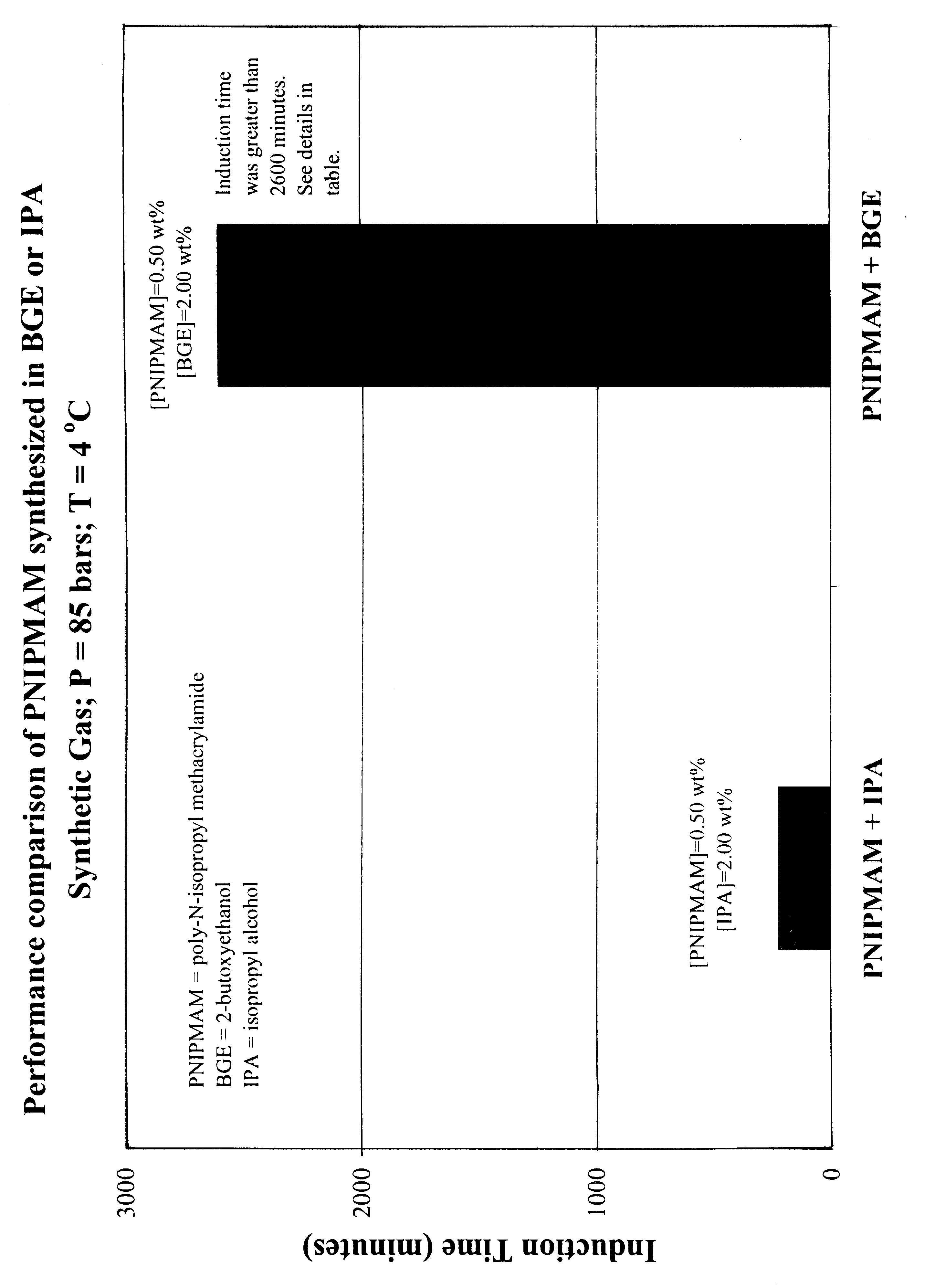

Method for preventing or retarding the formation of gas hydrates

A composition is provided herein for preventing or retarding the formation of gas hydrates or for reducing the tendency of gas hydrates to agglomerate, during the transport of a fluid comprising water and a hydrocarbon, through a conduit. The composition is a homopolymer of an N-alkyl(meth)acrylamide, N,N-dialkyl(meth)acrylamide or copolymers thereof with N-vinyl-N-methylacetamide, in a defined solvent, which homopolymers and copolymers are made and applied in the defined solvent, which, most preferably, is a low molecular weight glycol ether such as 2-butoxyethanol.

Owner:ISP CAPITAL

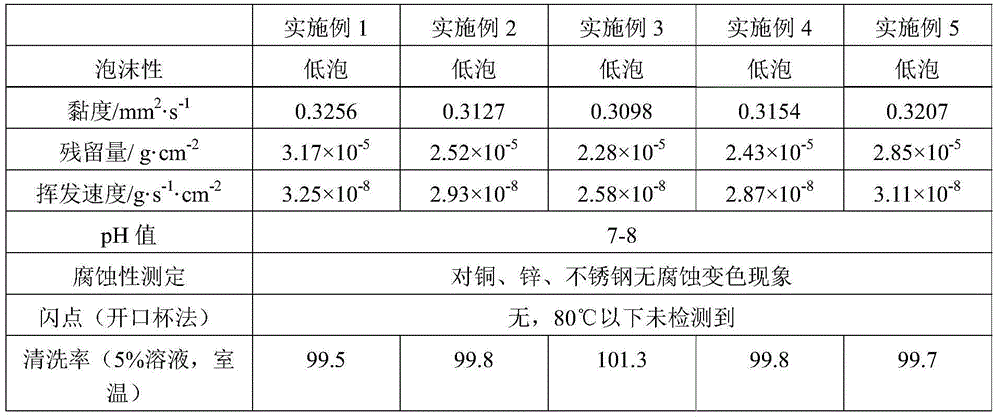

Cleaning agent for electronic element and preparation method thereof

InactiveCN104450282AEasy to cleanNot corrosiveOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsSodium bicarbonateSodium metasilicate

The invention provides a cleaning agent for an electronic element and a preparation method thereof. The cleaning agent is prepared from sodium dodecyl benzene sulfonate, polyethylene glycol, sodium metasilicate, sodium tripolyphosphate, isopropanol, sodium bicarbonate, nonylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether, N, N'-2-hydroxyethyl tridecyl amide, carboxymethyl cellulose sodium, coconut diethanolamide, 2-butoxyethanol, alcohol, triethanolamine, propylene glycol and deionized water. The preparation method comprises the steps of adding sodium dodecyl benzene sulfonate, polyethylene glycol, sodium metasilicate, sodium tripolyphosphate, sodium bicarbonate and carboxymethyl cellulose sodium to deionized water to obtain a mixed solution I; heating alcohol, isopropanol and propylene glycol until reaching azeotropy to obtain a mixture; adding nonylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether and 2-butoxyethanol to obtain a mixed solution II; mixing the mixed solution I and the mixed solution II; adding the rest components; heating to obtain the cleaning agent. The cleaning agent is small in foam, free of corrosion, little to be volatilized, few in residues and low in viscosity.

Owner:DONGCHEN LEADER TESTING

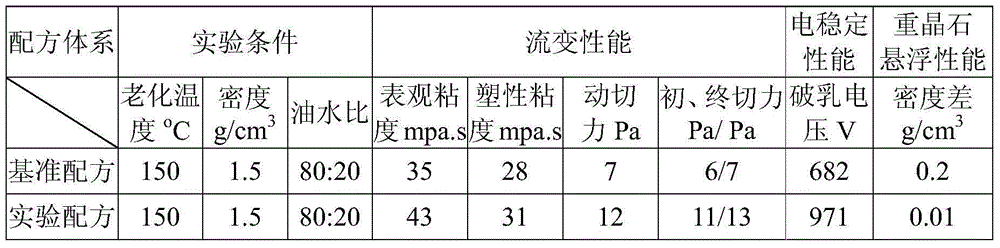

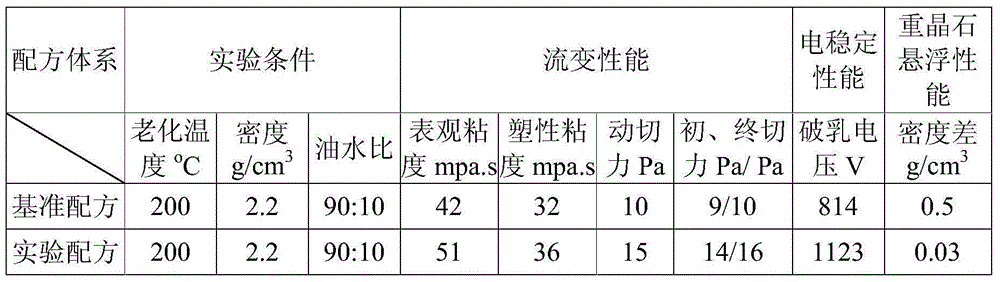

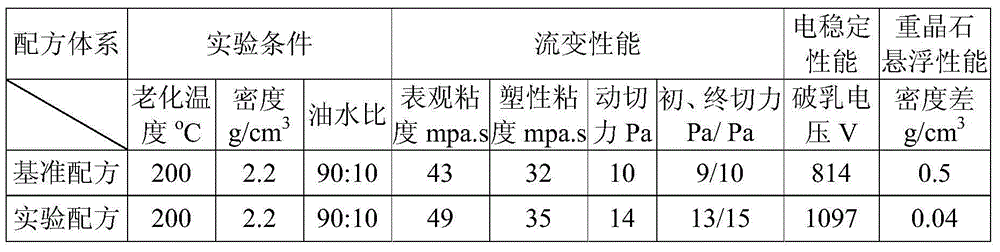

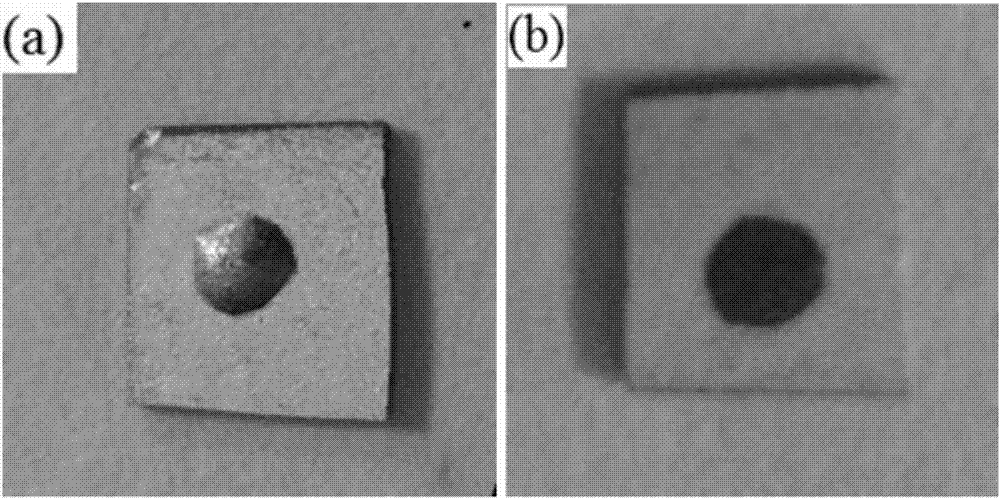

Enhancer for high-temperature resistant oil-based drilling fluid as well as preparation method and application of enhancer

InactiveCN104592959ASolve barite settlementSolve poor rock-carrying abilityDrilling compositionDimer acidEther

The invention provides enhancer for high-temperature resistant oil-based drilling fluid as well as a preparation method and application of the enhancer. The preparation method comprises the following steps: a, sequentially adding 150-250 parts by weight of dimer acids, 100-150 parts by weight of triethylene glycol momobutyl ether, 30-50 parts by weight of diethanol amine into a reaction container; stirring and performing heat reaction; b, adding 10-17 parts by weight of organic enamine for further reacting, and reducing the temperature after the reaction is finished; c, adding triethylene glycol momobutyl ether having the same weight parts in the step a and 20-30 parts by weight of propylene carbonate, uniformly stirring so as to obtain the enhancer for the high-temperature resistant oil-based drilling fluid. The invention also provides the enhancer for the high-temperature resistant oil-based drilling fluid prepared by using the preparation method and application of the enhancer in the oil-based drilling fluid. According to the enhancer, the shearing force of the oil-based drilling fluid can be improved, and the problems of barite sedimentation and poor carrying debris capability caused by low shearing force of the oil-based drilling fluid with high oil-water ratio can be solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

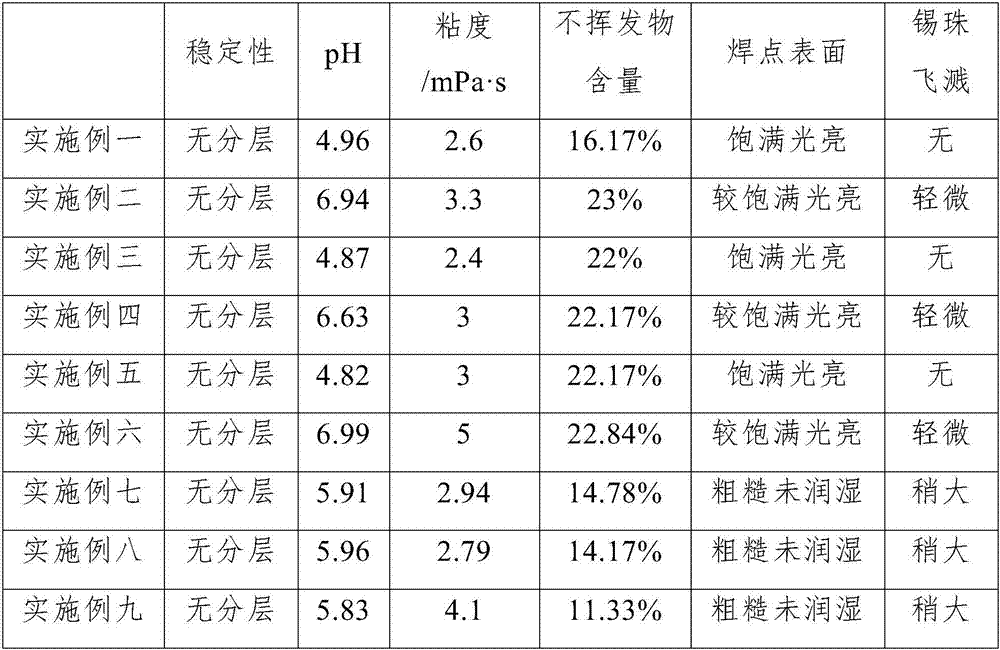

Non-cleaning flux for low temperature paste and preparing method of flux

InactiveCN107442970ASimple preparation processEasy to operateWelding/cutting media/materialsSoldering mediaActive agentAntioxidant

The invention discloses non-cleaning flux for low temperature paste, and a preparing method of the flux and belongs to the technical field of welding flux. The flux comprises, by mass percent, 79 to 82% of a compound solvent, 7 to 14% of an active agent, 2 to 5% of a thixotropic agent, 0.1 to 0.5% of a corrosion inhibitor, 1 to 8% of a pH conditioning agent, 0.5% of an antioxidant and 0.25% of a film-forming agent. The compound solvent is composed of a high-boiling-point organic solvent with the boiling point exceeding 200 DEG C and a low-boiling-point organic solvent with the boiling point lower than 200 DEG C, the high-boiling-point organic solvent is a mixture of ethylene glycol and ethylene glycol butyl ether, the low-boiling-point organic solvent is a mixture of one or two of ethyl alcohol and isopropyl alcohol, the active agent is lactic acid, the thixotropic agent is castor oil, the corrosion inhibitor is benzotriazole, the pH conditioning agent is organic amine, the antioxidant is toluic acid butyrate, and the film-forming agent is polyethylene glycol 2000. The method is simple in technology, operation is easy, the flux can be used in cooperation with flux powder with the melting point lower than 100 DEG C, activity is high, wettability is good, post-welding residue is little, corrosion resistance is high, and no tin sweat phenomenon happens.

Owner:NORTHEASTERN UNIV

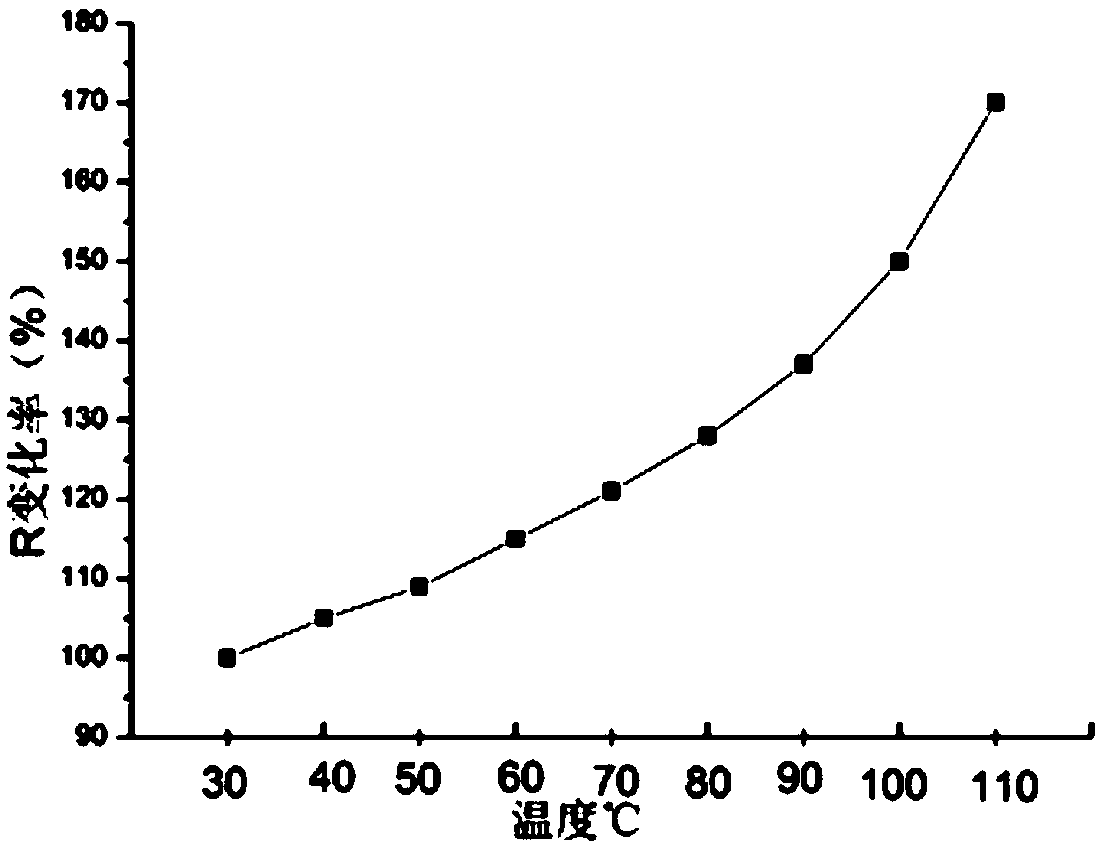

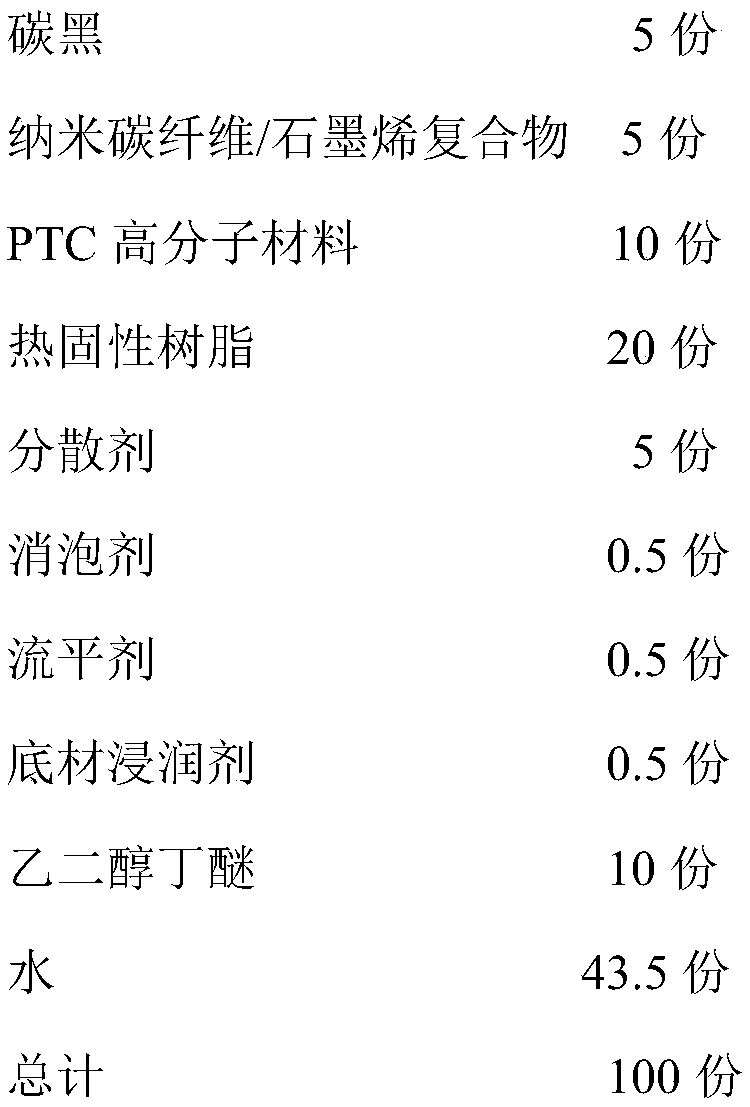

Preparation method of floor-heating electric heating plate

InactiveCN109280425AImprove adhesionImprove conductivityInksHeating element materialsFiberCarbon fibers

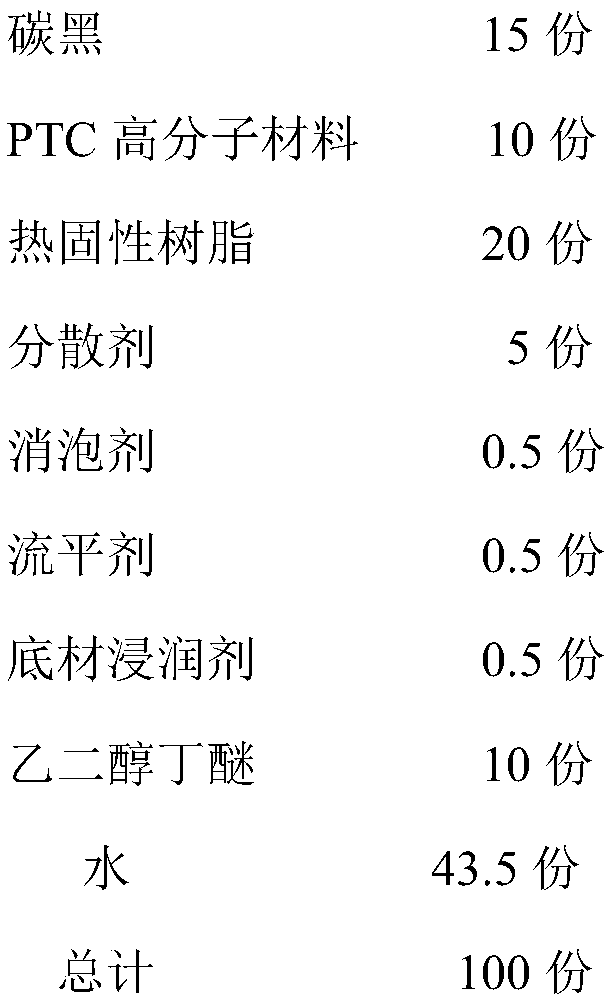

The invention discloses a preparation method of a floor-heating electric heating plate. The method comprises the following steps: (1) preparing gas-phase nano carbon fiber / graphene; (2) preparing gas-phase nano carbon fiber / graphene positive temperature coefficient (PTC) conductive ink; and (3) preparing the floor-heating electric heating plate. The PTC conductive ink is prepared by mixing the following components in parts by mass: 5 parts of carbon black, 5 parts of a gas-phase nano carbon fiber / graphene compound, 10 parts of a PTC polymer material, 20 parts of thermosetting resin, 5 parts ofa dispersing agent, 0.5 part of a defoaming agent, 0.5 part of a flattening agent, 0.5 part of a base material sizing agent, 10 parts of 2-butoxyethanol and 43.5 parts of water. The method is simplein process and is easy to operate, and the prepared floor-heating electric heating plate solves the construction problems such as high-temperature safety, leaked current generated during laying, and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Cleaning composition comprising cationic surfactants, chelant, and an alcohol solvent mixture

InactiveUS7045492B2Low flash pointReduce the possibilityInorganic/elemental detergent compounding agentsCationic surface-active compoundsEthylenediamineSolvent

A cleaning composition for treating and removing residue containing hydrocarbons and other flammable substances uses a mixture of one or more cleaning members containing quaternary salts, a chelator and a dispersant, mixed with water. The preferred cleaning members are tetradecyltrimethylammonium bromide, tetrasodium ethylenediaminetetraacetic acid, benzethonium hydrochloride and 2-butoxyethanol. The chelator is tetrasodium salt ethylenediamine of tetraacetic acid, and the dispersant is polyvinyl alcohol. Optionally, the cleaner contains ethanol and isopropyl alcohol.

Owner:JENEVEIN EARL

Environmentally friendly stone-like coating

The invention discloses environmentally friendly stone-like coating. The coating is prepared by the following raw materials in parts by weight: 0.05-0.15 parts of hydroxyethyl cellulose, 0.4-1.2 partsof 2,2,4-trimethyl-1,3-pentanediol mono(2-methylpropanoate), 0.2-0.8 parts of glycol, 0.05-0.15 parts of 2-amino-2-methyl-1-propanol, 15-30 parts of silicon acrylic emulsion, 50-100 parts of naturalcolor sand, 2-4 parts of rock sheets, 0.3-1.2 parts of 2-methoxyethanol, 0.3-1.2 parts of 2-butoxyethanol, and 5-10 parts of water. The stone-like coating has the advantages of gorgeous appearance color, water resistance, alkali resistance, good adhesion stress, and good ageing resistance; the product is suitable for a plurality of bases, and can be used for effectively protecting buildings from being eroded by severe environment, and prolonging usage life.

Owner:山东卓威新型材料有限公司

Wood preservative

InactiveUS20060189497A1High flash pointReduce the possibilityBiocideOrganic detergent compounding agentsEthylenediamineCopper sulfate

A wood preservative composition for treating wood to impart biocide and antimicrobial characteristics to wood contains a mixture of one or more cleaning members containing quaternary salts, an aromatic quaternary salt, a copper sulfate, a glycol ether and a chelator, mixed with water. The preferred active members are tetradecyltrimethylammonium bromide, tetrasodium ethylenediaminetetraacetic acid, benzethonium hydrochloride, copper sulfate pentahydrate and 2-butoxyethanol. The chelator is tetrasodium salt ethylenediamine of tetraacetic acid (EDTA).

Owner:JENEVEIN EARL

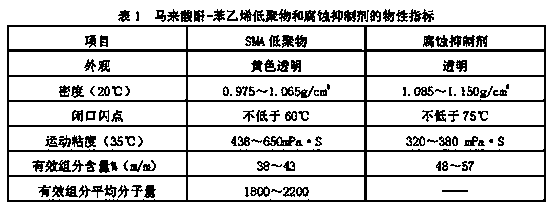

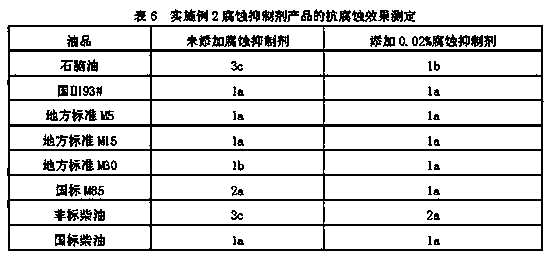

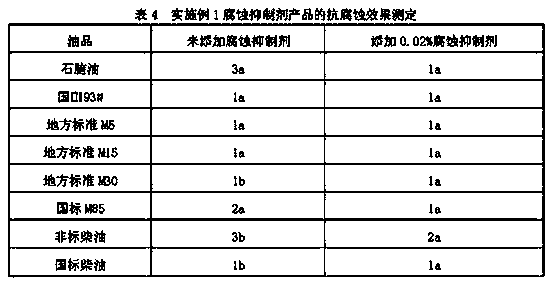

Corrosion inhibitor for alcohol ether fuel and preparation method for corrosion inhibitor

The invention relates to a corrosion inhibitor for alcohol ether fuel. A method for preparing the corrosion inhibitor comprises the following steps of: performing polymerization reaction of maleic anhydride and styrene by taking an alpha-methyl styrene dipolymer as a molecular weight regulator in a cyclohexanone solvent to obtain a maleic anhydride-styrene low polymer; adding water and polypropylene glycol 600, heating, distilling under reduced pressure and recovering cyclohexanone; and adding polypropylene glycol 2000 and ethylene glycol monobutyl ether to obtain the corrosion inhibitor. The corrosion inhibitor for the alcohol ether fuel has a simple preparation process, does not contain elements such as nitrogen, sulfur, phosphorus and the like which are harmful to environment, and is low in cost, high in intermiscibility with multiple oils and little in addition amount; and compared with the common corrosion inhibitor sold in markets, the corrosion inhibitor has an obvious anti-corrosion effect in various oils.

Owner:CRPC INNOVATION ENERGY

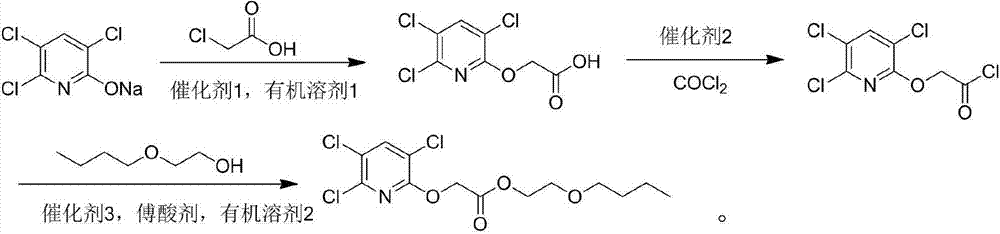

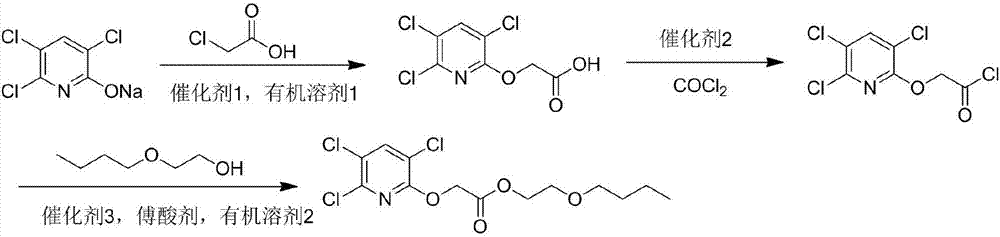

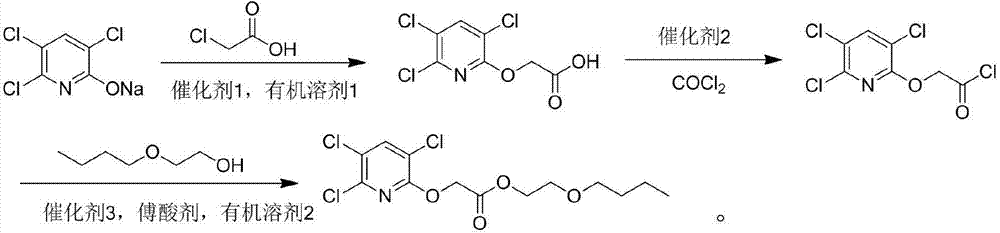

Preparation method of herbicide triclopyr butoxyethyl ester

The invention discloses a preparation method of an herbicide, namely triclopyr butoxyethyl ester, belonging to the field of pesticide chemistry. The preparation method is implemented by the steps of reacting by virtue of raw materials including sodium trichloropyridinol and chloroacetic acid in the presence of a catalyst 1 and an organic solvent, so as to obtain picolinic acid type triclopyr (triklopir) as a raw material, preparing acyl chloride from triclopyr, carrying out condensation reaction by virtue of acyl chloride and 2-butoxyethanol in the presence of a catalyst 2, an acid-binding agent and an organic solvent, so as to obtain triclopyr butoxyethyl ester. The content of triclopyr butoxyethyl ester is 95.2%, and the yield is 85.6%; the synthesis is easy in operation, the post-treatment is simple and convenient, wastewater is little, and the preparation method is suitable for preparing the herbicide, namely triclopyr butoxyethyl ester.

Owner:武汉华邦化学新材料有限公司

Composition with extracts from olive leaf, yarrow and rosemary for treating human diseases and conditions

ActiveUS8535737B2Avoiding many problemEffectively and safely boostBiocideNervous disorderOlive leafRosmarinus

The present invention is a medical composition for treating a variety of human diseases and conditions. It comprises an effective amount of Olive Leaf extract, Yarrow extract and Rosemary extract as active components. Its inactive components include Yucca extract and Cassia Oil. Other inactive components for the purpose of efficient delivery are hereafter identified as “Limonene Concentration Formulation”, comprising d-Limonene (C10H16), Glycol EB (2-Butoxyethanol), Calimulse PRS (Benzenesulfonic acid, C10-16-alkyl derivatives, compounds with 2-propanamine), Calsoft L-60 (Benzenesulfonic acid, C10-16-alkyl derivatives, sodium salts, Sodium xylene sulfonate, sodium sulfate), Isopar M Solvent (Light Hydro treated Petroleum Distillates), and Water. This composition can easily enter the circulatory system and quickly reach target tissue and / or organs. Hence it will promote the process of restoring and healing the patient by boosting his or her immune system.

Owner:TIEU HUU +1

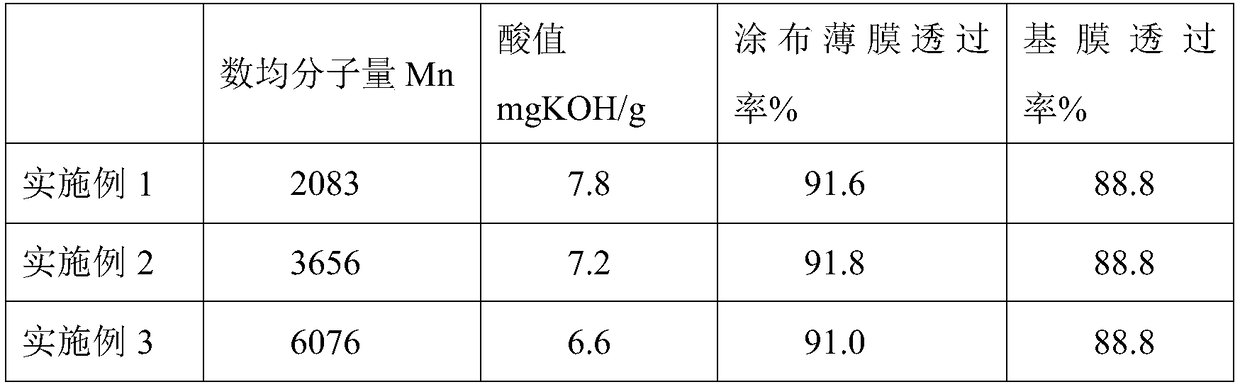

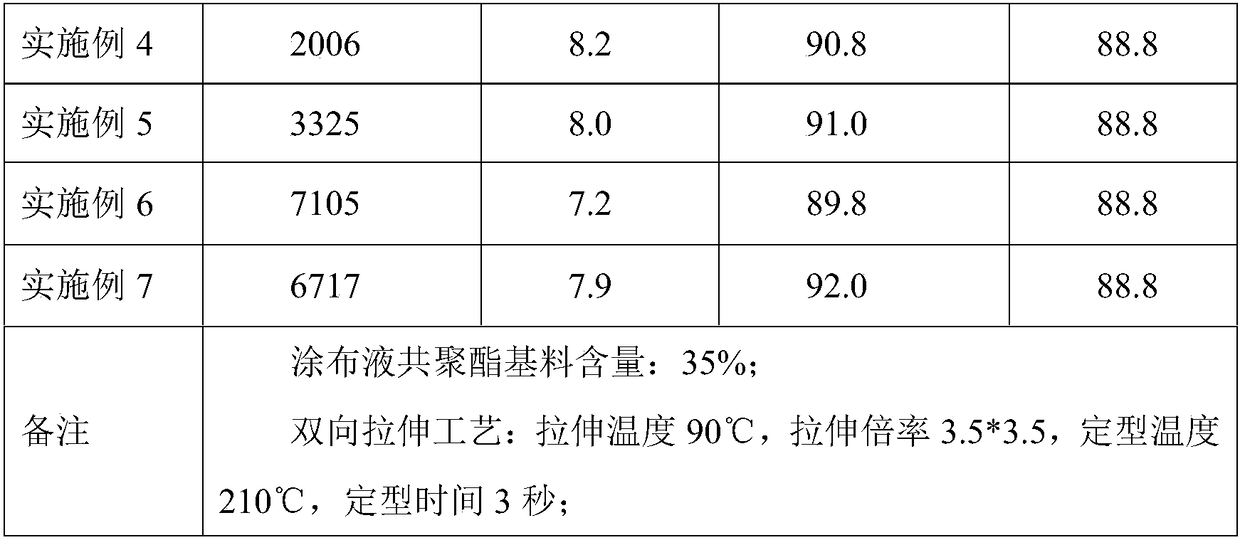

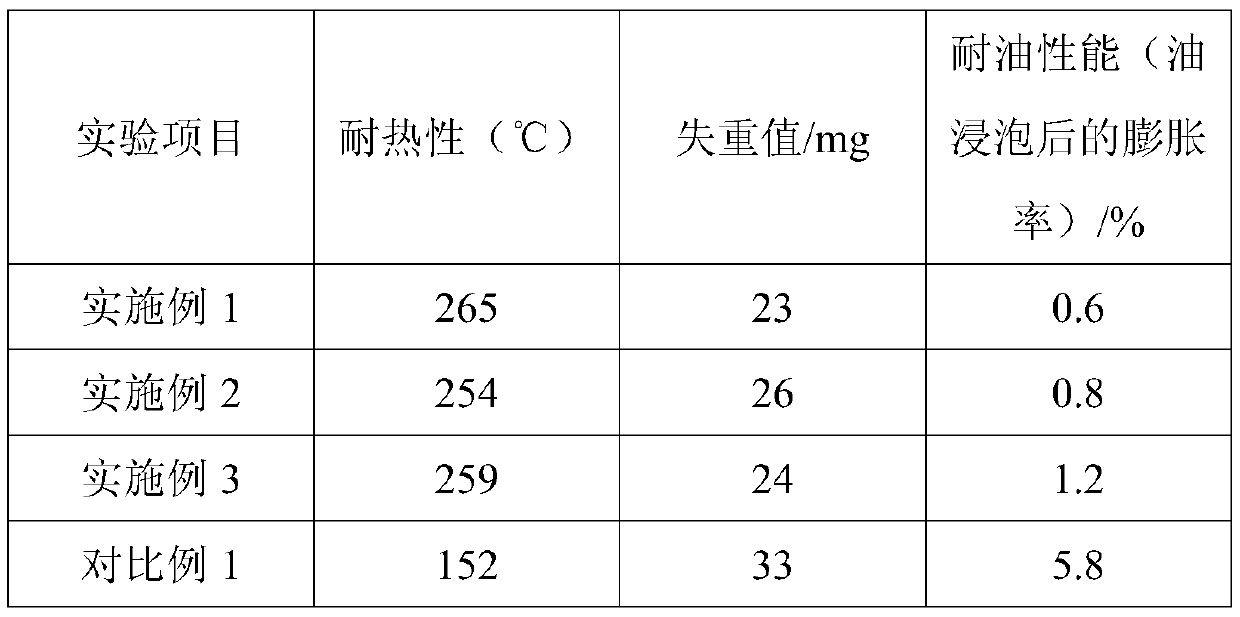

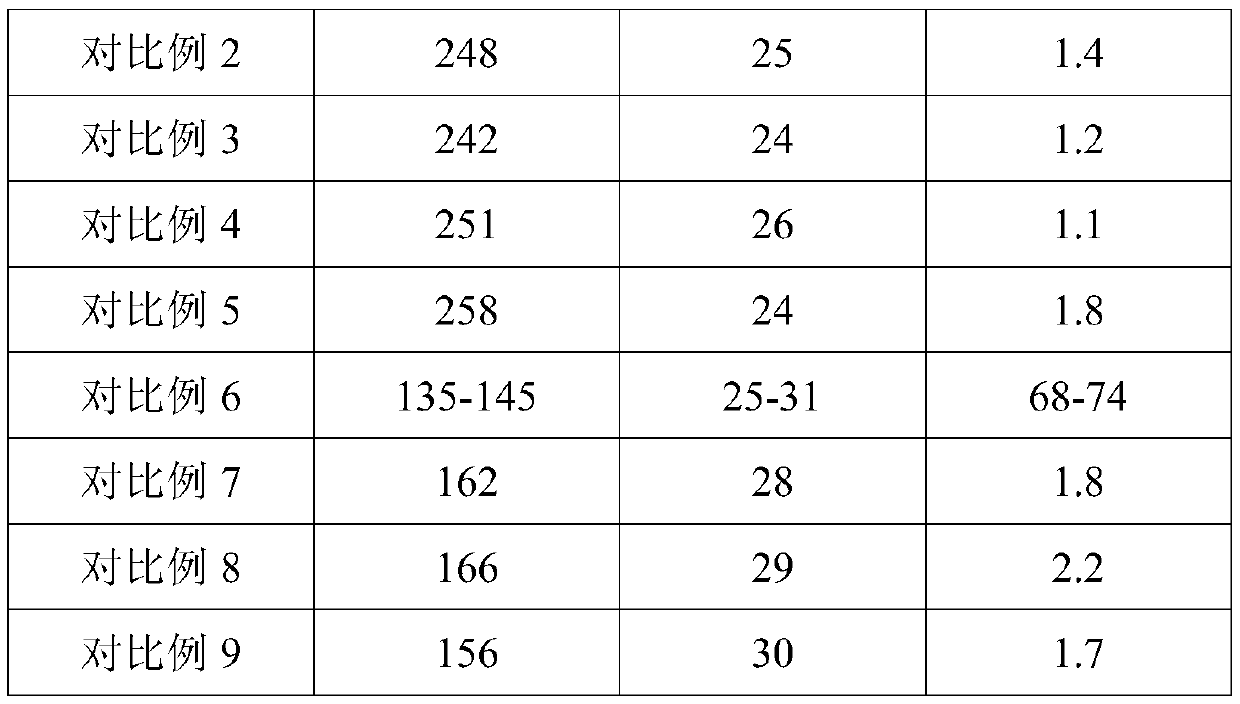

Waterborne copolyester and preparation method thereof

The invention relates to novel waterborne copolyester and a preparation method thereof. Copolyester has good water solubility, can be used as a base material for preparing a waterborne coating liquid,and is mainly used for production and manufacture of online coated film products. Copolyester is prepared by steps that a dibasic acid monomer and a diol monomer are subjected to esterification and condensation polymerization under the action of a catalyst, a stabilizer, an ether inhibitor and a waterborne monomer, then copolyester is generated, 2-butoxyethanol is added for stirring, and the product is obtained; number-average molecular weight (Mn) of copolyester is 2000-8000, and acid value is smaller than 10 mgKOH / g. The waterborne coating liquid prepared from waterborne copolyester as thebase material has good stability and is directly applied to a PET film without need of adding any refraction particles, and after biaxial stretching and heat setting treatment, transmittance of a BOPET film can be improved.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Cleaning solution for smoking paraphernalia and method therefor

InactiveUS9365809B1Organic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsAlcoholCarboxylic acid

A cleaning solution for smoking paraphernalia and other cleaning surfaces which may comprise: carboxylic acid, dipropylene glycol monomethyl ether, iodized salt, isopropyl alcohol, 2-butoxyethanol, ethylene glycol n-hexyl ether, and water. The solution may also contain grain alcohol and raw lemon. The solution may be combined with water and then heated prior to being applied to the soiled surface for cleaning.

Owner:710 CLEANER LLC

Quick-drying environment-friendly printing ink and preparation method thereof

The invention discloses quick-drying environment-friendly printing ink. The quick-drying environment-friendly printing ink comprises deionized water, pigment permanent red F4R, pigment fast scarlet, molybdate red 107, nitrocellulose, polyamide liquid resin, 2-butoxyethanol, octyl acetate, tricresyl phosphate, butyl acetate, sodium sulfate, polyethylene microcrystalline wax, a dispersing agent, a connection material, a wetting agent and methyl silicone. The printing ink is bright in color and high in tinting strength, and the expressive force of the printing ink reaches up to 91%-95%; surface dryness can be achieved in 0.9-1.6 seconds, full dryness can be achieved in 1.5-3.5 seconds, the cost is reduced by 25%-45%, and deterioration cannot happen when the printing ink is stored for 12-24 months; zero-VOC emission is realized, no solvent residues exist, food packages cannot be polluted, and environmental protection and health are achieved.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Comprehensive printed circuit board cleaning agent and preparation method thereof

InactiveCN103525568AGood recombinationStrong PH buffering capacityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringCleansing Agents

The invention relates to a comprehensive printed circuit board cleaning agent which is prepared from the raw materials of, by weight: 2-3 parts of sodium silicate, 3-4 parts of Tween-85, 2-3 parts of sodium tripolyphosphate, 12-15 parts of 2-butoxyethanol, 1-2 parts of benzalkonium chloride, 4-5 parts of isopropyl myristate, 1-2 parts of sodium hydroxide, 4-5 parts of inositol hexaphosphate, 4-5 parts of an auxiliary agent, and 100-120 parts of deionized water. The surfactant of the cleaning agent has good complounding performance. The cleaning agent has the advantages of high pH buffering capacity, comprehensive penetration, good cleaning effect, and low corrosion. The cleaning agent is suitable for the cleaning of various high-precision circuit board cleaning. With the auxiliary agent, a protective film can be formed on the surface of the circuit board, such that the circuit board can be prevented from being corroded by water and other molecules in the atmosphere, and also oxidation and short-circuit can be prevented. Therefore, the next step of manufacturing process can be conveniently carried out.

Owner:合肥市华美光电科技有限公司

Cardanol modified waterborne insulating varnish and preparation method thereof

The invention discloses cardanol modified waterborne insulating varnish and a preparation method thereof. The cardanol modified waterborne insulating varnish is prepared from raw materials in parts by weight as follows: 14-20 parts of cardanol, 17-21 parts of isophthalic acid, 9-15 parts of trimethylolpropane, 12-18 parts of neopentyl glycol, 7-9 parts of pyromellitic dianhydride, 7-9 parts of maleic anhydride, 12-16 parts of methylated amino resin, 7-10 parts of dimethylethanolamine, 16-17 parts of 2-butoxyethanol and 0.1-1 part of a water-based dispersing agent. Use of toluene, dimethylbenzene, styrene and solvent oil which are taken as a solvent is avoided, the production cost is reduced, environmental pollution is reduced, health of workers is guaranteed, and the raw materials such as cardanol and the like are widely sourced, and the waterborne insulating varnish has the advantages of low cost and simple production technology; meanwhile, water is taken as the solvent, production is low-carbon, and the waterborne insulating varnish has the advantages that the varnish is energy-saving, environmentally friendly and safe to transport, has low risk and has no harm to a human body.

Owner:JIANGXING JIASHENG INSULATION MATERIAL CO LTD

High-temperature resistant water-borne flashing coating used for photo frames

InactiveCN106085064AOrientation effect is goodImprove high temperature resistanceFireproof paintsPolyurea/polyurethane coatingsSodium bicarbonateFerric oxide yellow

High-temperature resistant water-borne flashing coating used for photo frames is disclosed. Raw materials of the coating include water-borne resin, hydroxy-containing polyacrylate emulsion, a cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethyl ethanolamine, triethylamine, triethanolamine, 2-amino-2-methyl-1-propanol, ammoniacal liquor, glycidyl acrylate, 2-butoxyethanol, aqueous aluminium powder, charcoal powder, talcum powder, sodium bicarbonate, glass fibers, vermiculite powder, perlite powder, EVA wax, polyethylene wax, nanometer titanium dioxide, a water-borne polyisocyanate curing agent, a wetting agent, a dispersant, a defoaming agent, a levelling agent and an anti-settling agent BYK-420. The flashing coating has excellent resistance to high temperatures.

Owner:蚌埠市禹会区贵宾装饰材料商行

Nano heat-dissipation paint

InactiveCN103773121AGood compatibilityImprove the level ofCoatingsDibutyl tin dilaurateCyclohexylamines

The invention discloses a nano heat-dissipation paint which is prepared from the following raw materials in parts by weight: 94 to 100 parts of high density polyethylene, 1 to 2 parts of nano titanium dioxide, 2 to 3 parts of 2-butoxyethanol, 3 to 4 parts of nano carbon powder, 5 to 6 parts of nano sepiolite powder, 2 to 4 parts of light calcium carbonate, 0.2 to 0.4 part of nickel aminosulfonate, 1 to 2 parts of sodium tripolyphosphate, 0.5 to 1 part of dibutyltin dilaurate, 1 to 2 parts of N,N-dimethyl cyclohexylamine and 6 to 10 parts of modified filling material. The nano heat-dissipation paint contains multiple nano raw materials, so that the compatibility among all the raw materials is enhanced; the heat-dissipation paint is good in fillibility, so that the levelling property and the smoothness on the surface of a painting layer are enhanced. As a result, the nano heat-dissipation paint is good in heat dissipation.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Composite elastomer plastic door and window

The present invention discloses a composite elastomer plastic door and window, which is composed of the following raw materials by weight: 5-7 parts of epoxidized soybean oil, 3-4 parts of 1,2-dimethylimidazole, 10-14 parts of thermoplastic elastomer TPE G130D, 60-70 parts of 20-30% sodium hydroxide solution, 30-41 parts of dimethyl carbonate, 2-3 parts of op-10, 20-30 parts of n-butyl acrylate, 0.4-0.6 part of ammonium persulfate, 60-70 parts of vinyl acetate, 36-40 parts of benzyl chloride, 400-430 parts of polyvinyl chloride, 2-4 parts of tea tree oil, 2-3 parts of sodium tripolyphosphate, 2-4 parts of monoethanolamine, 6-10 parts of oyster shell powder, 42-50 parts of graphite, 1-3 parts of 2-butoxyethanol and 6-10 parts of sisal fiber. The sisal fiber is treated by microwave to improve dispersion of cellulose and to increase the accessibility of benzyl chloride to cellulose; after etherification treatment, the number of hydroxy decreases, and the crystalline structure of cellulose is destroyed, so as to obtain thermoplasticity.

Owner:阜阳市锐达不锈钢制品销售有限公司

Permeable floor polyurethane finish paint and preparation method thereof

InactiveCN110041738AIncrease surface areaImprove heat resistanceFireproof paintsAntifouling/underwater paintsCyclohexanoneDiethylenetriamine

The invention discloses permeable floor polyurethane finish paint and a preparation method thereof. The permeable floor polyurethane finish paint comprises the following raw materials: hydroxy acrylicresin, chlorinated rubber, E-20 epoxy resin, xylene, butyl acetate, ethyl acetate, cyclohexanone, 2-butoxyethanol, N,N'-ethylenebis(stearamide), silicone oil, polyethylene-polypropylene glycol, gaseous silicon dioxide, titanium dioxide, corundum powder, diethylenetriamine, xylene, ethyl acetate, butyl acetate, a heat-resistant modification additive, expandable graphite, magnesium hydroxide, a silane coupling agent KH-570, and an oil-resistant modification additive. The permeable floor polyurethane finish paint is prepared by steps of base material preparation, modification material preparation, mixing of base materials, modification materials and additives and the like. The permeable floor polyurethane finish paint of the invention has excellent heat and oil resistance.

Owner:长沙如洋环保科技有限公司

Solvent for liquid ingredients to be used in effervescent products

InactiveUS20020127183A1Reduce solubilityInorganic/elemental detergent compounding agentsInorganic boron active ingredientsSolubilitySodium bicarbonate

An effervescent compound is disclosed which includes a solvent and an effervescent system. The solvent may be both hydrophilic and have low solubility with organic effervescent ingredients. The solvent may include a glycol ether, for example, but not limited to, 2-butoxyethanol. The effervescent system used in the effervescent compound may be, for example, but is not limited to, expanded sodium perborate or a mixture of sodium bicarbonate, sodium carbonate, and an acid. The effervescent compound may further include any one, or all, or any combination of the following ingredients: surfactants, bleaching compositions, anti-redeposition agents, binders, lubricants, colors, fragrances, and / or optical brighteners. Also disclosed is a method for making an effervescent compound, including the steps of providing a solvent, providing an effervescent system in powder form, and mixing the solvent with the effervescent system, thereby producing a free-flowing effervescent compound. The method disclosed may also include the steps of compressing the effervescent compound, and then forming either granules or a tablet.

Owner:DESENNA RICHARD A +3

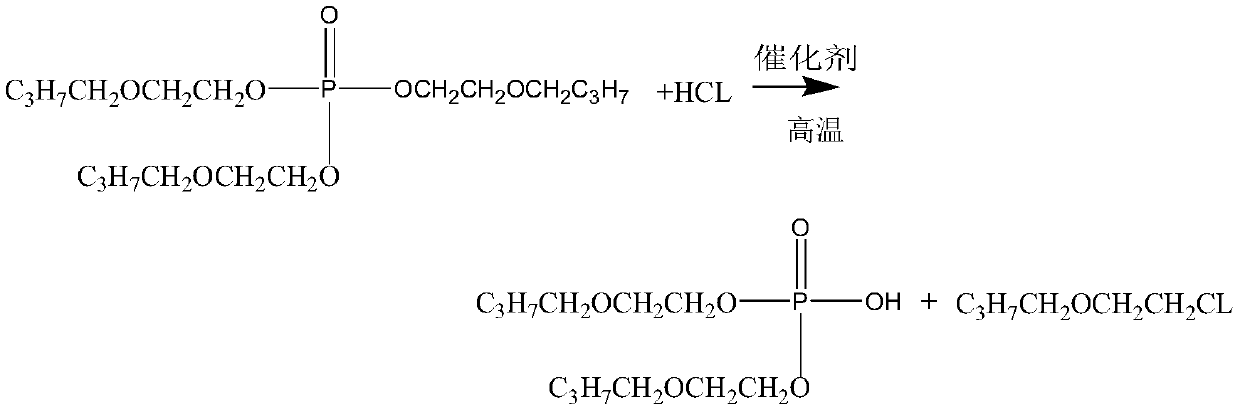

Industrial preparation method of high-purity tris(2-butoxyethyl)phosphate

The invention relates to a preparation method of high-purity tris(2-butoxyethyl)phosphate. The method comprises the following steps: 1) reacting phosphorus oxychloride with ethylene glycol monobutyl ether under a vacuum condition under the action of a Lewis catalyst; 2) carrying out vacuum distillation after the reaction is finished to recover a large amount of ethylene glycol monobutyl ether, andstopping distillation when the content of ethylene glycol monobutyl ether in the reactant 5-10%; 3) performing neutralization by using an alkali to make the pH value be 5-8, carrying out reduced pressure distillation, and stopping distillation until the content of the ethylene glycol monobutyl ether content is less than 0.1% in order to obtain a crude product; and 4) washing the crude product with water to separate, and carrying out reduced pressure distillation on the washed product to remove water in order to obtain the high-purity tris(2-butoxyethyl)phosphate. The method provided by the invention is simple, and greatly improves the purity, the color number and the yield of the product.

Owner:ZHEJIANG WANSHENG

Vegetable water retention agent

InactiveCN103734273AGood moisturizing effectRipeness and aromaFruit and vegetables preservationLocust bean gumGalactomannanase

The present invention provides a vegetable water retention agent, which comprises, by weight, 10-20 parts of benzyl alcohol, 0.1-0.8 part of galactomannanase, 100-150 parts of locust bean gum, 900-1200 parts of water, 1-5 parts of artemisinin, 1-3 parts of maslinic acid, and 0.5-2 parts of 2-butoxyethanol, wherein the viscosity of the fresh keeping agent aqueous solution with a mass percentage of 5% is 27CPS. The vegetable water retention agent has advantages of simple ratio, easy use, good water retention effect and good fresh keeping effect. The vegetable water retention agent specifically has the following characteristics that: the maturity of the fruits and the vegetables adopting the vegetable water retention agent to carry out fresh keeping is not changed, the odor is fragrant, the taste is good, the weight is only reduced by 2.8%, and the good water retention and moisturizing effect is provided.

Owner:时洪良

Solarization-resistant metallic paint

Disclosed solarization-resistant metallic paint is prepared from the following raw materials in parts by weight: 30-50 parts of polyacrylamide, 5-10 parts of an acrylate associative thickener, 50-90 parts of deionized water, 5-15 parts of calcium phytate, 8-16 parts of propanediol ether, 6-9 parts of 2-butoxyethanol, 4-9 parts of ammonium hydroxide, 4-8 parts of mica powder, 5-10 parts of ethyl acetate, 4-8 parts of damage-resistant jade powder, 10-16 parts of meerschaum, 15-25 parts of N-tert-butyl-2-benzothiazolesulfenamide, 3-7 parts of hematic acid, 10-20 parts of aluminium-silver paste, and 7-9 parts of sodium polycarboxylate. The provided solarization-resistant metallic paint is excellent in film-forming property, good in stability, resistant to solarization and resistant to explosion, and is capable of keeping original luster and brightness in sunlight.

Owner:QINGDAO JISHUNLONG TRADING

Manufacturing method of glass embossment

The invention provides a manufacturing method of a glass embossment. The manufacturing method comprises the following steps that patterns of a screen printing plate are designed as required, acid-resisting printing ink is printed on glass through the screen printing plate, then drying or airing is conducted, the acid-resisting printing ink is composed of, by weight, 32-60 parts of epoxy resin, 12-24 parts of 2-butoxyethanol, 3-8 parts of cyclohexanone and 7-16 parts of aromatic hydrocarbon, the obtained glass is taken and placed in an etching bath with an etching solution for etching, the etching time is 20-50 minutes, the etching solution comprises the components, by volume, 25-35 parts of hydrofluoric acid, 3-8 parts of sulfuric acid and 60-75 parts of water, the obtained glass is taken, residual etching solution on the glass is cleaned through alkali liquor, the obtained glass is taken, the acid-resisting printing ink on the glass is removed through a cleaning agent, and then drying or airing is conducted. Through the manufacturing method, the patterns are designed and engraved in the screen printing plate, the formed patterns can be controlled more easily, the accuracy is high, engraving is conducted with the etching solution, one-step forming is achieved, the procedures are simple, operation is convenient, and the manufacturing efficiency is high.

Owner:东莞市银泰玻璃有限公司

Water-based chipping resistant coating for automobiles

The invention discloses a water-based chipping resistant coating for automobiles. The water-based chipping resistant coating comprises following raw materials, by mass: 180 to 190 portions of styrene-acrylic acid-2-ethylhexyl-acrylic acid polymer, 9 to 12 portions of heavy calcium carbonate, 10 to 15 portions of silicon carbide micro powder, 0.9 to 1.8 portions of sodium hexametaphosphate, 10 to 15 portions of 2-butoxyethanol, 1 to 5 portions of dimethylaminoethanol, 30 to 38 portions of aluminium triphosphate, 0.5 to 1 portion of polyoxyethylene octylphenol ether and 18 to 25 portions of deionized water, wherein the solid content of styrene-acrylic acid-2-ethylhexyl-acrylic acid polymer is 45 to 50%, and the particle size of silicon carbide micro powder is 1200 meshes. Adhesive force of the water-based chipping resistant coating on metal is high, and the level of adhesive force is grade 1 when the temperature is 30 or -30 DEG C; chipping resistance of the water-based chipping resistant coating is excellent, and the level of chipping resistance is grade 1; the level of the appearance of the water-based chipping resistant coating is grade 2; the water-based chipping resistant coating can be used for automobile outer metal plate, mudapron, front fender, and the like, and is suitable for air spraying.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

Low-foam cleaning agent for cleaning wool carpet

InactiveCN103060108AGood removal effectDoes not damage the materialOrganic detergent compounding agentsSurface-active detergent compositionsFiberCleansing Agents

The invention discloses a low-foam cleaning agent for cleaning a wool carpet. The low-foam cleaning agent comprises the following raw materials: Span-65, Tween-85, sodium tripolyphosphate, 2-butoxyethanol, benzalkonium chloride, inositol hexaphosphate, oxalic acid, polyether, polydimethylsiloxane, copper sulfate pentahydrate and water. Compared with the prior art, the low-foam cleaning agent disclosed by the invention has excellent pollution removing ability and can basically avoid the production of foam during the cleaning process, and the water consumption for rinsing is obviously lower than that of an existing product. Furthermore, harmful bacteria in gaps between fibers of the carpet can be effectively killed, the material of the wool carpet is not damaged, and the original color, luster and hand feeling can be restored after cleaning.

Owner:如皋市五山漂染有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com