Corrosion inhibitor for alcohol ether fuel and preparation method for corrosion inhibitor

A corrosion inhibitor and fuel technology, which is applied in the directions of fuel additives, fuels, and liquid carbon-containing fuels, can solve the problems of unfriendly combustion products, reduced adhesion, and reduced anticorrosion performance, and achieves obvious anticorrosion effect. Less and less cost effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

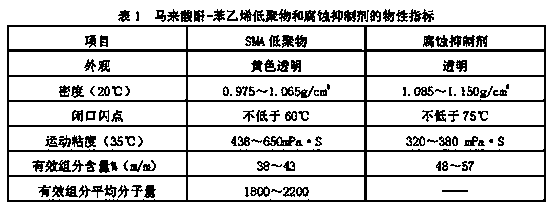

[0019] Add 24kg cyclohexanone, 8.25kg styrene, 0.12kg benzoyl peroxide, 1.05kg α-methylstyrene dimer in a stainless steel polymerization kettle with a reflux device, then add 7.75kg maleic anhydride, 25 rpm / min stirring and dissolving, the oil bath was heated to 104°C to start the reaction, and the reaction was completed for 6 hours to obtain 39.2 kg of maleic anhydride-styrene oligomer with a weight average molecular weight ranging from 1920 to 2160.

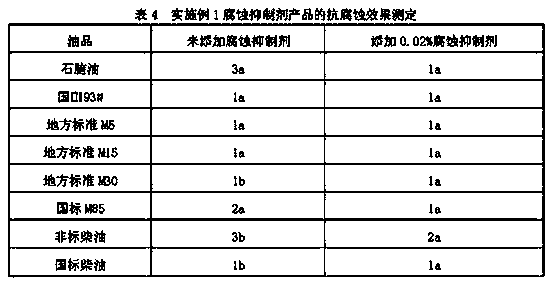

[0020] Add 38.5kg of maleic anhydride-styrene oligomer into the stirred tank, then add 0.70kg of water, 20kg of polypropylene glycol 600, heat to 78°C, stir for 3 hours, then connect the decompression device, and keep the vacuum under 100mmHg Under certain conditions, heat up to 90°C to distill out cyclohexanone and recover it, remove the vacuum distillation device, add 20kg of polypropylene glycol 2000, 45.3kg of ethylene glycol monobutyl ether, stop heating, stir and cool down to room temperature to obtain alcohol ether 99.6...

Embodiment 2

[0025] Add 170kg cyclohexanone, 67kg styrene, 0.78kg benzoyl peroxide, 7.8kg α-methylstyrene dimer in a stainless steel polymerization kettle with a reflux device, then add 63kg maleic anhydride, 30 rpm Stir to dissolve, heat the oil bath to 101°C to start the reaction, react for 6 hours, and complete the reaction to obtain 302 kg of maleic anhydride-styrene oligomer with a weight average molecular weight ranging from 1850 to 2100.

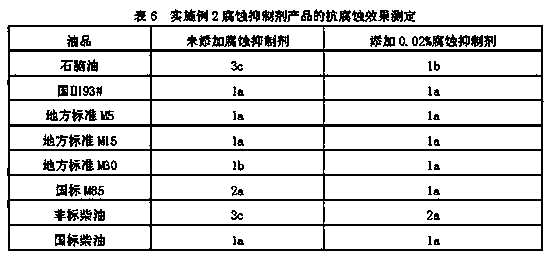

[0026] Add 284.5kg of maleic anhydride-styrene oligomer into the stirred tank, then add 5.4kg of water, 180kg of polypropylene glycol 600, heat to 73°C, stir and react for 3 hours, then connect the decompression device, when the vacuum degree is lower than 100mmHg Under certain conditions, raise the temperature to 90°C to distill out cyclohexanone and recover it, remove the vacuum distillation device, add 224.6kg of polypropylene glycol 2000, 470kg of ethylene glycol monobutyl ether, stop heating, stir and cool down to room temperature to obtain al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com