Normal-temperature nonphosphorus degreasing agent for metal surface processing and preparation method thereof

A metal surface treatment and degreasing agent technology, applied in the field of non-phosphorus degreasing agent at room temperature, can solve the problems of high foam, easy anti-contamination of oil stains, poor degreasing effect, etc., and achieve low foam and good degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

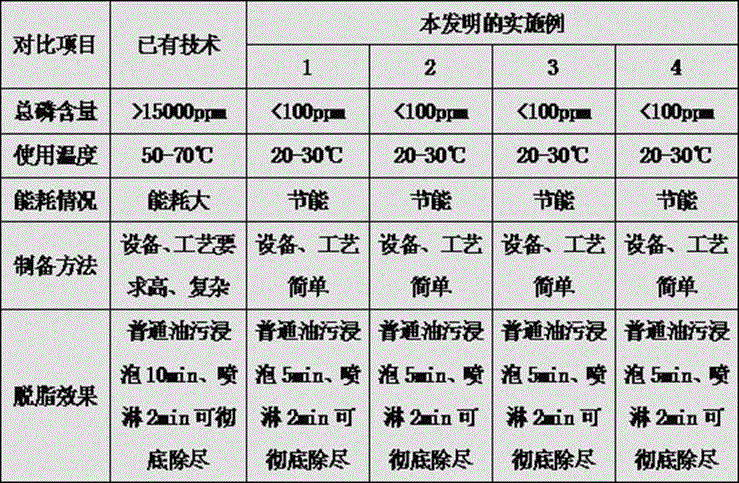

Examples

Embodiment 1

[0020] Embodiment 1: be used for the normal temperature phosphorus-free degreasing agent of metal surface treatment, the weight percent of its composition raw material is:

[0022] Sodium metasilicate 5%

[0024] Alkylphenol ethoxylates 6%

[0025] Linear Alkylbenzene Sulfonate 4%

[0026] 2-Butoxyethanol 2%

[0027] Polyether 0.5%

[0028] water balance

[0029] The preparation method of the normal temperature phosphorus-free degreasing agent used for metal surface treatment comprises the following steps:

[0030] (1) Weigh each raw material according to the weight percentage of the constituent raw materials, first put sodium hydroxide and water into the reaction kettle, stir and wait for it to completely dissolve, and place it for 2 hours;

[0031] (2) Then put sodium metasilicate and sodium carbonate into water in sequence, fully dissolve and add to the alkali solution in step (1), stir evenly; then add alkyl...

Embodiment 2

[0033] Embodiment 2: be used for the normal temperature non-phosphorus degreasing agent of metal surface treatment, the weight percent of its composition raw material is:

[0034] Sodium Hydroxide 20%

[0035] Sodium metasilicate 5%

[0036] Sodium carbonate 3%

[0037] Alkylphenol ethoxylates 8%

[0038] Linear Alkylbenzene Sulfonate 2%

[0039] 2-Butoxyethanol 1%

[0040] Polyether 1%

[0041] water balance

[0042] The preparation method is the same as in Example 1.

Embodiment 3

[0043] Embodiment 3: be used for the normal temperature non-phosphorus degreasing agent of metal surface treatment, the weight percent of its composition raw material is:

[0044] Sodium Hydroxide 15%

[0045] Sodium metasilicate 7.5%

[0046] Sodium carbonate 4%

[0047] Alkylphenol ethoxylates 7%

[0048] Linear Alkylbenzene Sulfonate 3%

[0049] 2-Butoxyethanol 2%

[0050] Polyether 0.5%

[0051] water balance

[0052] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com