Permeable floor polyurethane finish paint and preparation method thereof

A polyurethane topcoat and permeable floor technology, which is applied in the field of polyurethane topcoat, can solve the problems of insufficient heat resistance and oil resistance of permeable floor polyurethane topcoat, and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

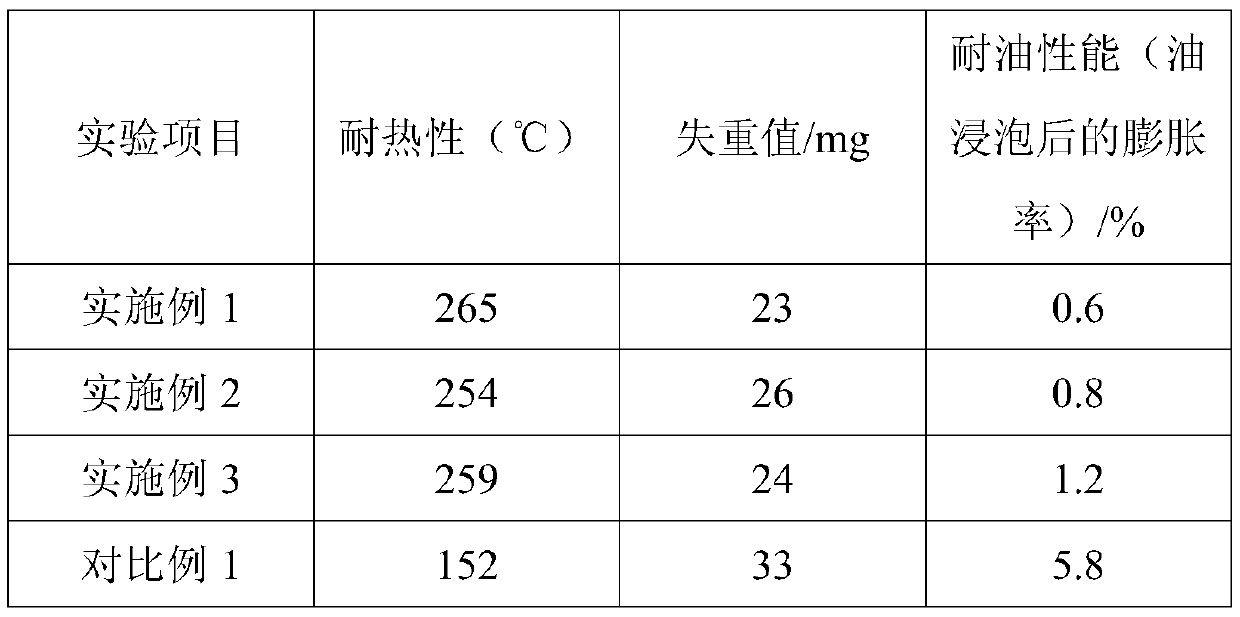

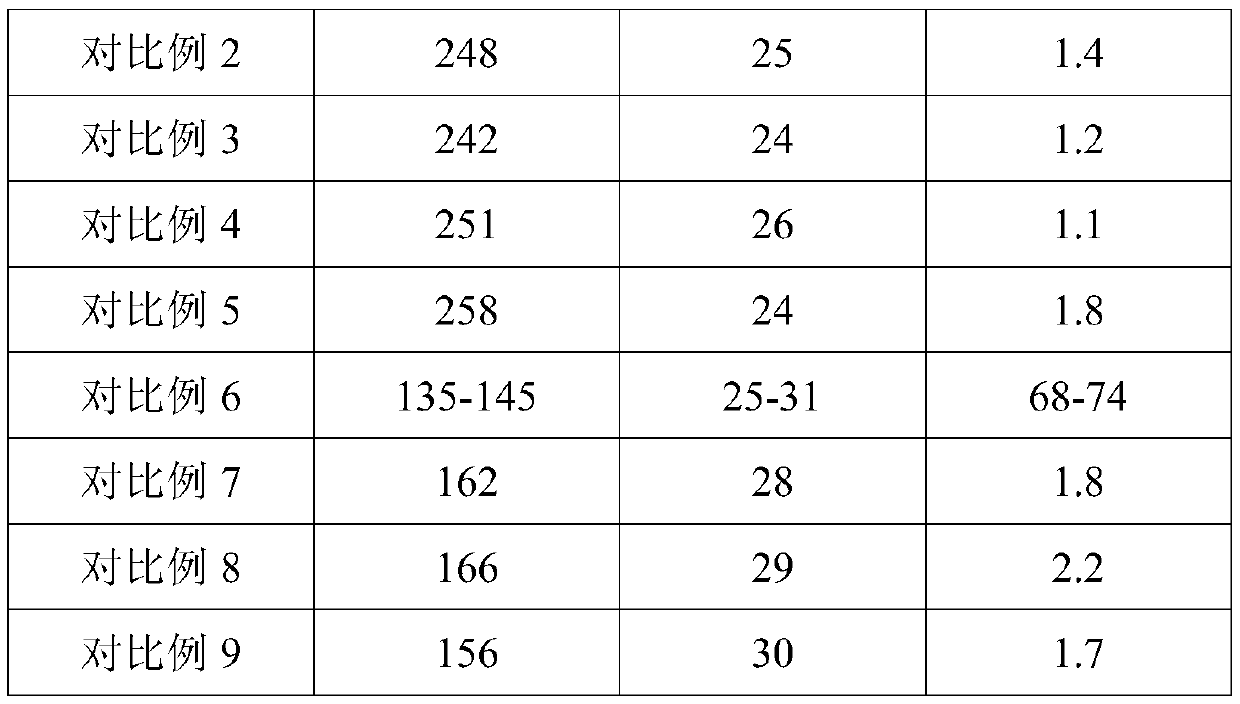

Examples

preparation example Construction

[0032] The present invention also proposes a preparation method of a permeable floor polyurethane topcoat, comprising the following steps:

[0033] S1. Mix hydroxyacrylic resin, chlorinated rubber, xylene, ethyl acetate, cyclohexanone, ethylene glycol monobutyl ether, xylene, ethyl acetate, and butyl acetate evenly, heat up to 110-120°C, and keep warm 10-20min, then disperse at 1500-2500r / min for 25-45min, then add fumed silica, titanium dioxide and corundum powder and mix evenly, disperse at 300-1000r / min for 15-25min, cool down to 80-90℃ , keep warm for 5-15min, then add E-20 epoxy resin, vinylbisstearamide, silicone oil, polyoxypropylene oxide ethylene glyceryl ether and diethylenetriamine and mix evenly, after stirring evenly, let it stand for 1-3h to obtain the base material;

[0034] S2. Mix 10-20 parts of heat-resistant modification additive, silane coupling agent KH-570 and oil-resistant modification additive evenly, stir at 600-800r / min for 1-3h, and then add expanda...

Embodiment 1

[0038] A kind of permeable floor polyurethane topcoat, with parts by weight as the unit, comprising the following raw materials: 100 parts of hydroxyl acrylic resin, 20 parts of chlorinated rubber, 6 parts of E-20 epoxy resin, 4.5 parts of xylene, 5 parts of butyl acetate , 3 parts of ethyl acetate, 6 parts of cyclohexanone, 6 parts of ethylene glycol monobutyl ether, 4 parts of vinyl bis stearamide, 3 parts of silicone oil, 4.5 parts of polyoxypropylene oxide glyceryl ether, 4.5 parts of fumed silica 3 parts of titanium dioxide, 6 parts of corundum powder, 4.5 parts of diethylenetriamine, 5 parts of xylene, 3 parts of ethyl acetate, 6 parts of butyl acetate, 20 parts of heat-resistant modification additives, 2.5 parts of expandable graphite , 7.5 parts of magnesium hydroxide, 2 parts of silane coupling agent KH-5702, 15 parts of oil resistance modification additive.

[0039] The heat-resistant modification additive is prepared according to the following process: 20 parts of p...

Embodiment 2

[0046] A kind of permeable floor polyurethane topcoat, with parts by weight as the unit, comprising the following raw materials: 80 parts of hydroxyacrylic resin, 25 parts of chlorinated rubber, 4 parts of E-20 epoxy resin, 6 parts of xylene, 2 parts of butyl acetate , 5 parts of ethyl acetate, 4 parts of cyclohexanone, 9 parts of ethylene glycol monobutyl ether, 2 parts of vinyl bis stearamide, 5 parts of silicone oil, 3 parts of polyoxypropylene oxide glyceryl ether, 7 parts of fumed silica 1 part, titanium dioxide 1 part, corundum powder 8 parts, diethylenetriamine 3 parts, xylene 8 parts, ethyl acetate 1 part, butyl acetate 8 parts, heat-resistant modification additive 15 parts, expandable graphite 4 parts , 6 parts of magnesium hydroxide, 3 parts of silane coupling agent KH-5703, 10 parts of oil resistance modification additive.

[0047] The heat-resistant modification additive is prepared according to the following process: 15 parts of polymethyl methacrylate, 16 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com