Deep red phosphor for LED plant growth lamp and preparation method thereof

A plant growth lamp and phosphor technology, applied in the directions of botanical equipment and methods, horticultural methods, chemical instruments and methods, etc., to achieve the effects of easy operation, wide excitation range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

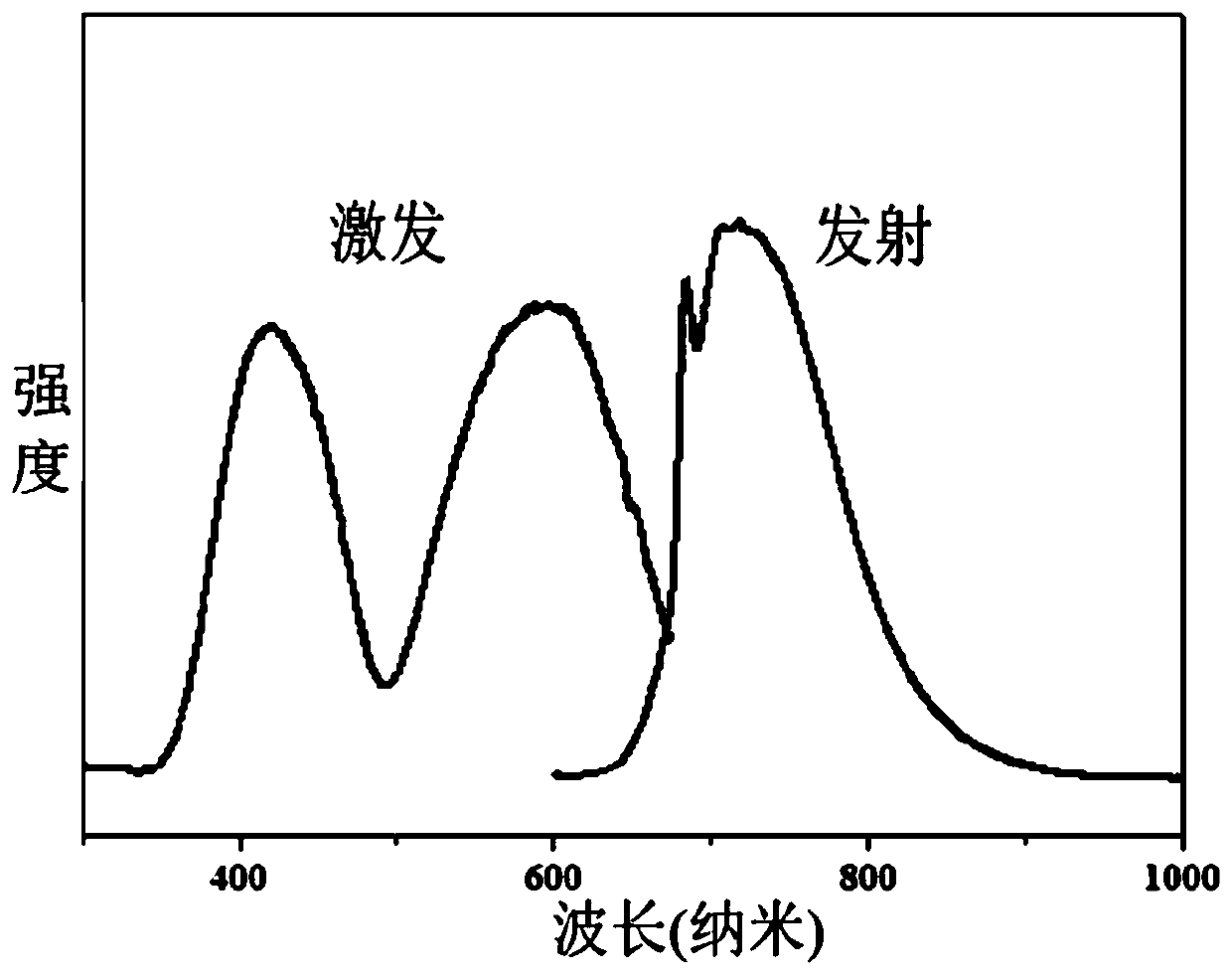

[0032] Weigh raw material Y 2 o 3 0.005 mol, Al 2 o 3 0.0144 mol, H 3 BO 3 0.056 mol, Cr 2 o 3 0.0006 mol. After the raw materials are fully mixed, they are sintered in air at 1250°C for 10h. The resulting product is fully ground, washed three times with deionized water, and dried at 80° C. to obtain the deep red phosphor of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached figure 1 shown.

Embodiment 2

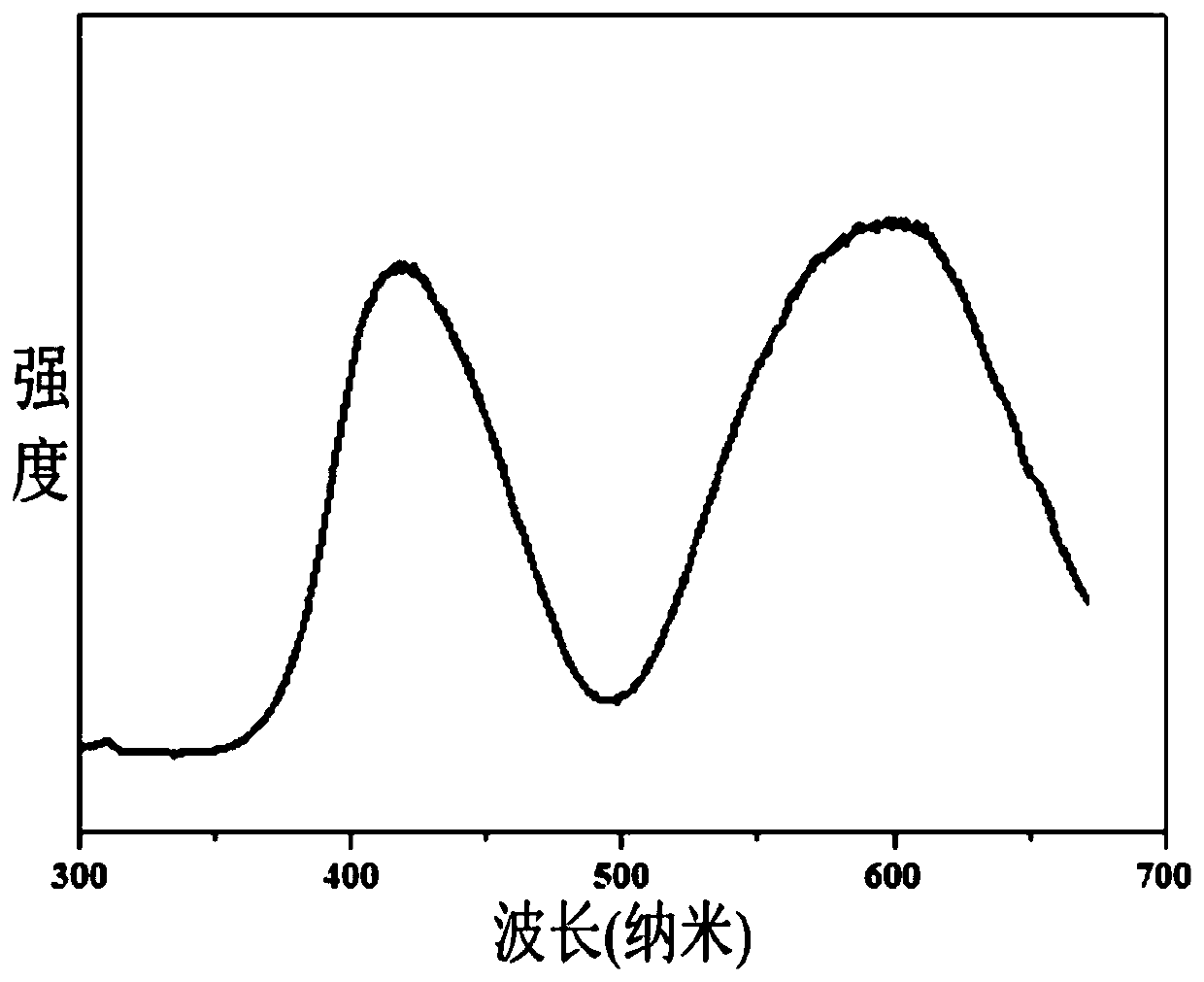

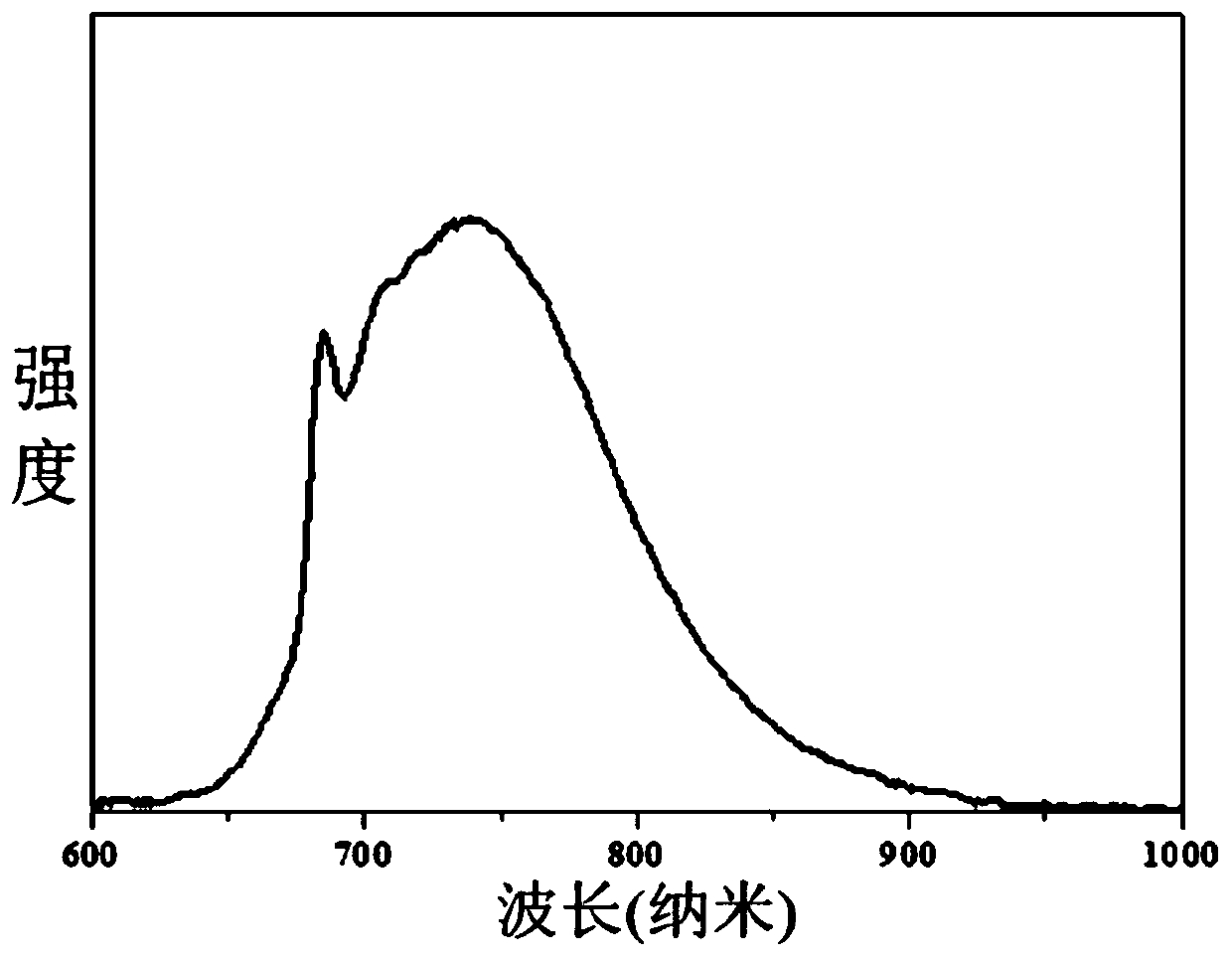

[0034] Weigh raw material Gd 2 o 3 0.005 mol, Al 2 o 3 0.0144 mol, H 3 BO 3 0.056 mol, Cr 2 o 3 0.0006 mol, weigh 1% AlF by raw material weight 3 as a flux. After fully mixing the raw materials and flux, sinter in air at 1200°C for 5h. After the calcined product is fully ground, it is fired a second time at 1200°C for 10 hours in air. The resulting product was ground, washed three times with deionized water, and dried at 100° C. to obtain the deep red phosphor of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached figure 2 , 3 shown.

Embodiment 3

[0036] Weigh raw material Lu 2 o 3 0.005 mol, Al 2 o 3 0.0144 mol, H 3 BO 3 0.056 mol, Cr 2 o 3 0.0006 mol, weigh 5% AlF of raw material weight 3 as a flux. After fully mixing the raw materials and flux, sinter in air at 1200°C for 20h. After the calcined product is fully ground, it is washed three times with deionized water and dried at 120° C. to obtain the deep red phosphor of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached Figure 4 , 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com