Germinate green long-afterglow light-emitting material and preparation method thereof

A technology of long-lasting luminescence and germanate, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unable to meet the needs of lighting, limit the application range, and prone to phase transition, etc., and achieve the benefit of pilot test and production , High luminous efficiency, not easy to hydrolyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

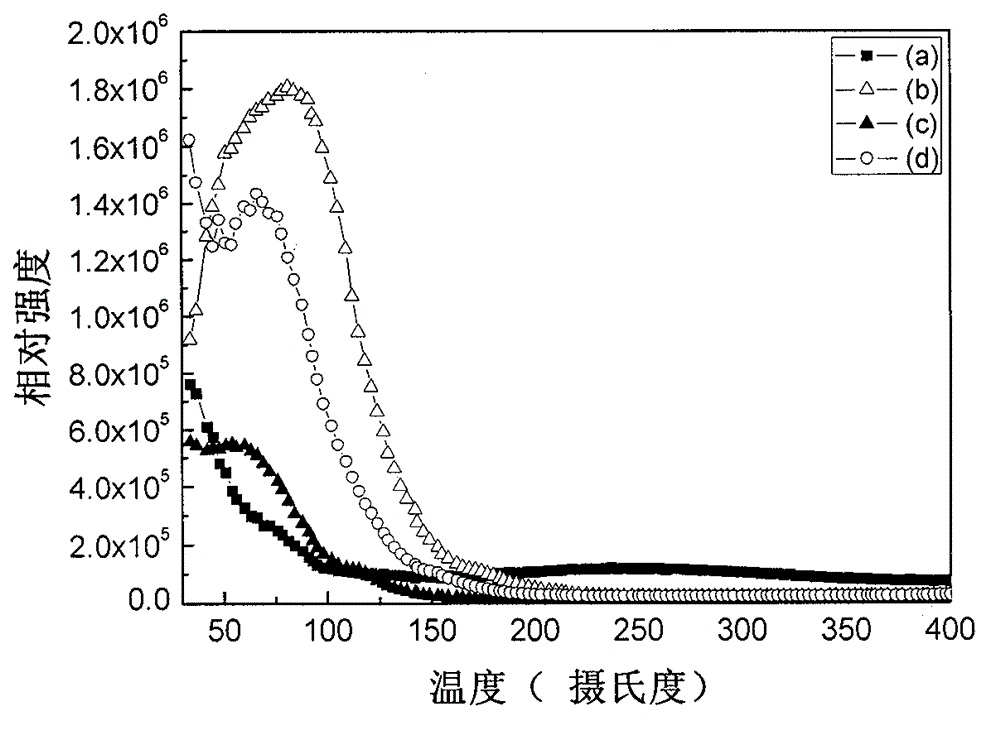

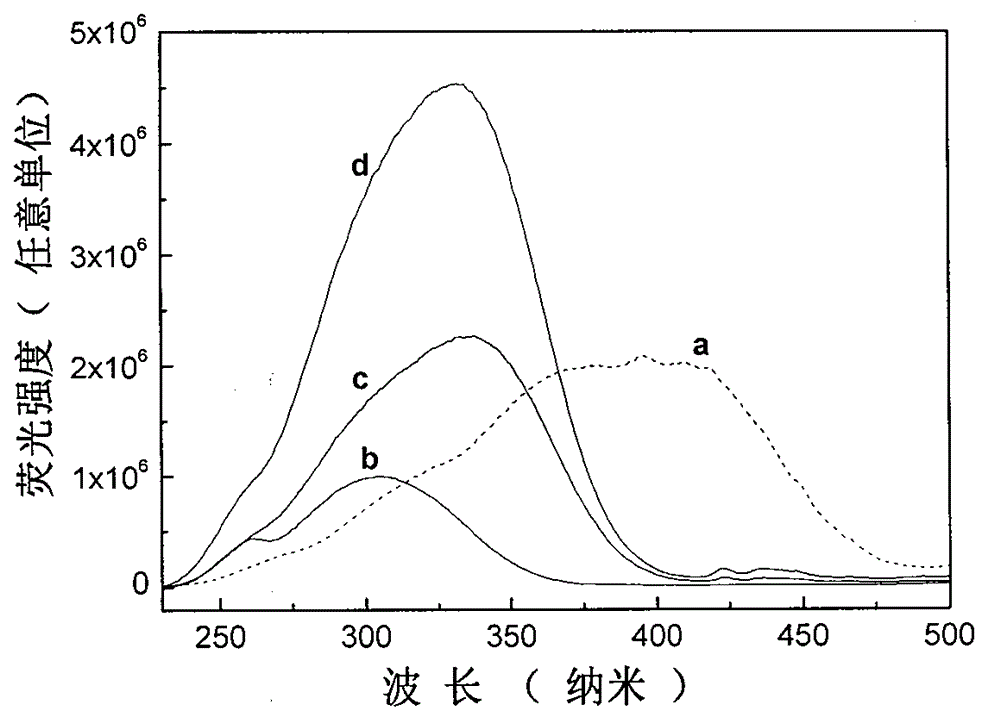

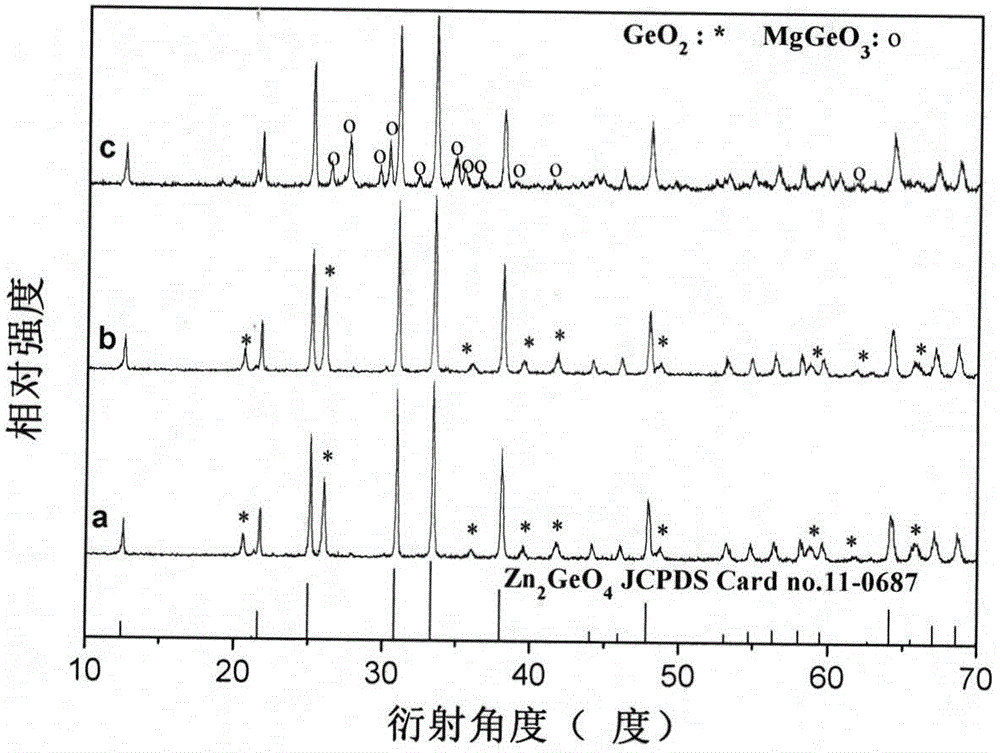

[0020] According to ZnO:GeO 2 :Mn 2+ =2 (1-0.02): 1.5: 0.02 molar ratio, respectively accurately weigh 0.7976g solid zinc oxide ZnO (analytical pure), 0.7845 solid germanium oxide GeO 2 (analytical pure), 0.0245g solid manganese acetate Mn(Ac) 2 4H 2 O (analytically pure), fully grind for 30 minutes to make the mixture uniform. Under air conditions, put the mixture in a muffle furnace at 700°C for 5 hours, take it out after cooling, and grind it again for 10 minutes to obtain a precursor, put the precursor into the air at -1100°C for 3 hours, and cool Take it out to get the product. Utilize XRD powder diffractometer (Bruker D8Advance) to detect the phase of product under room temperature condition, as figure 1 As shown in a, XRD shows that the product is pure Zn 2 GeO 4 phase; the material emits bright green light under the irradiation of ultraviolet light; using Fluoromax-4 fluorescence spectrometer (HORIBA Jobin Yvon Inc.), the luminescence properties of the product a...

Embodiment 2

[0022] According to ZnO:GeO 2 :Mn 2+ =2(1-0.001):1.5:0.001 molar ratio, accurately weigh 0.8131g solid zinc oxide ZnO (analytical pure), 0.7845g solid germanium oxide GeO respectively 2 (analytical pure), 0.0012g solid manganese acetate Mn(Ac) 2 4H 2 O (analytically pure), fully grind for 20 minutes to make the mixture uniform. Under air conditions, put the mixture in a muffle furnace at 600°C to melt for 4 hours, take it out after cooling, and grind it again for 20 minutes to obtain a precursor, put the precursor in the air at 1000°C for 4 hours, and take it out after cooling , the product is obtained. Utilize XRD powder diffractometer (Bruker D8Advance) to detect the phase of product under room temperature condition, show that product is pure Zn 2 GeO 4 Phase; using Fluoromax-4 fluorescence spectrometer (HORIBA Jobin Yvon Inc.), detect the luminescence performance of the product at room temperature, the product is excited at a wavelength of 336nm and emits a broad band...

Embodiment 3

[0024] According to ZnO:GeO 2 :Mn 2+ =2(1-0.08):1.5:0.08 molar ratio, accurately weigh 0.7487g solid zinc oxide ZnO (analytical pure), 0.7845g solid germanium oxide GeO respectively 2 (analytical pure), 0.0980g solid manganese acetate Mn(Ac) 2 4H 2 O (analytically pure), fully grind for 30 minutes to make the mixture uniform. Under air conditions, put the mixture in a muffle furnace at 800°C for 3 hours, take it out after cooling, and grind it again for 20 minutes to obtain a precursor, put the precursor in the air at 900°C for 5 hours, and take it out after cooling , the product is obtained. Utilize XRD powder diffractometer (Bruker D8Advance) to detect the phase of product under room temperature condition, show that product is pure Zn 2 GeO 4 phase; Utilize Fluoromax-4 fluorescence spectrometer (HORIBA Jobin Yvon Inc.) to detect the luminescent performance of the product at room temperature, the product is excited at a wavelength of 336nm and emits a wide band of 490-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com