Threaded connection rotor structure of turbine thermoelectric conversion system

A technology of thermoelectric conversion and screw connection, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems affecting the reliability of the closed cycle turbine thermoelectric conversion system, reduce the connection strength of the rotor, and poor repeatability of assembly, so as to improve The effects of running stability and working reliability, reducing mass and moment of inertia, and reducing space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0039] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

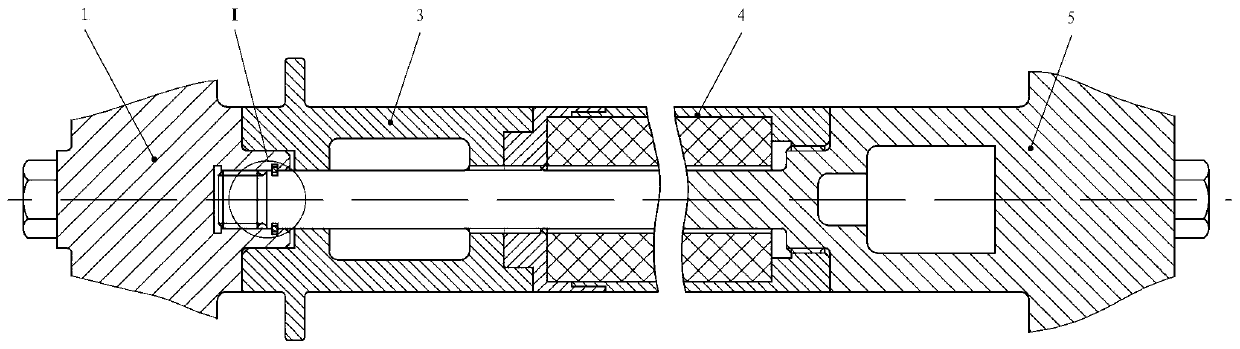

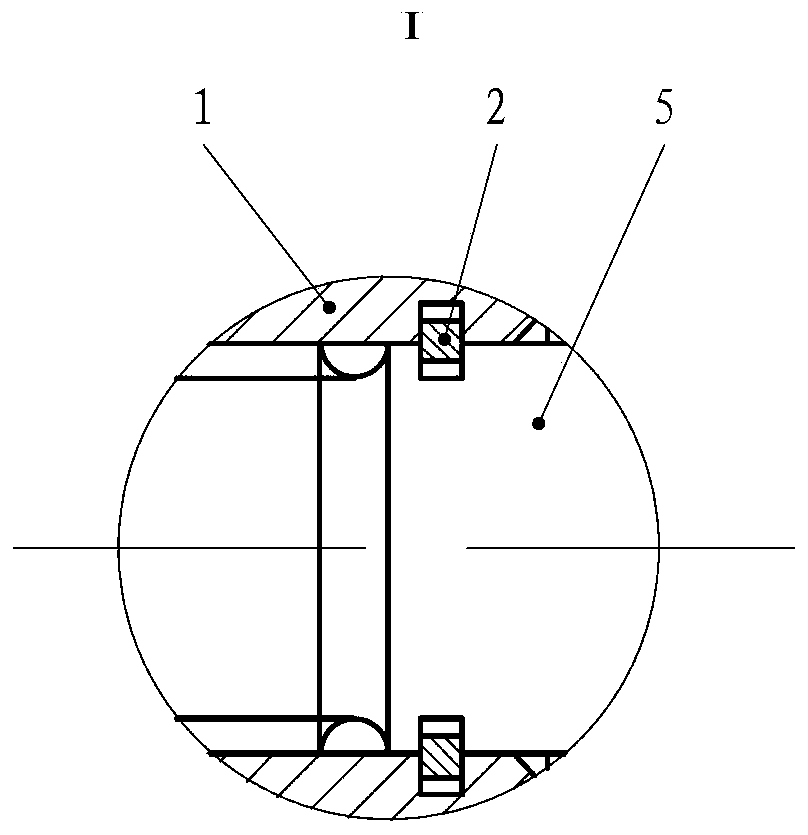

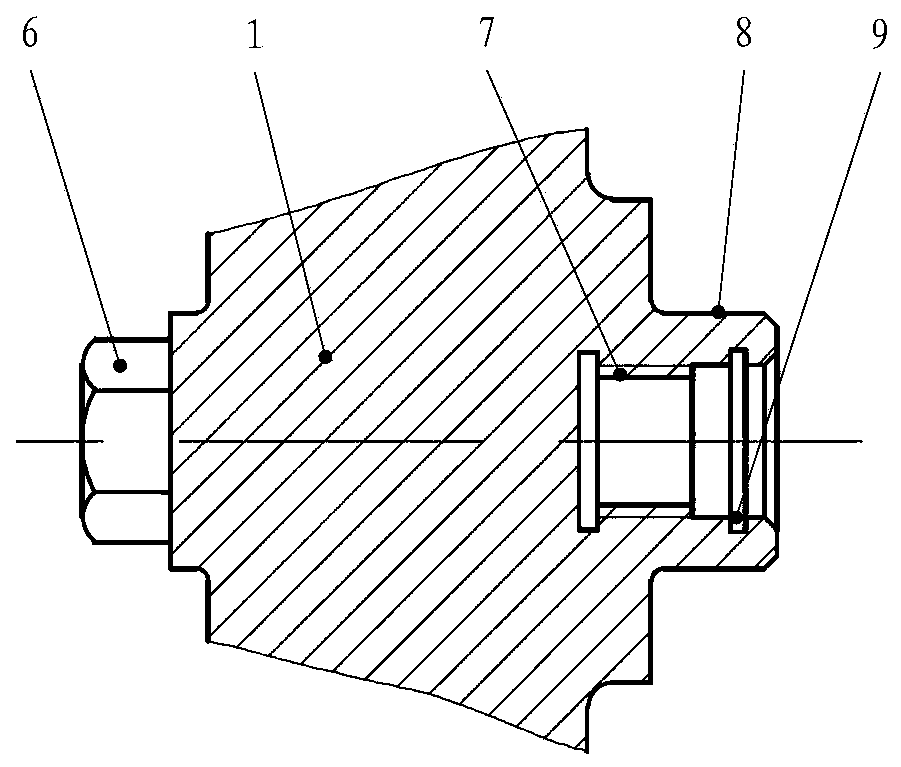

[0040] A threaded connection rotor structure of a turbine thermoelectric conversion system includes a compressor impeller 1, a locking ring 2, a shaft sleeve 3, a motor shaft 4 and a turbine rotating shaft 5. The compressor wheel 1 has a threaded hole 7 assembled with the turbine shaft. The internal thread of the threaded hole 7 of the compressor wheel 1 is the same as the rotation direction of the rotor of the turbine power generation system when it is working. The compressor wheel 1 There is a coaxially sleeved outer cylindrical surface 8, the compressor impeller 1 has a locking ring groove 9 assembled with a locking ring, and the air inlet end of the compressor impeller 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com