A method for characterization of laser cladding layer and molten pool morphology

A technology of molten pool morphology and laser cladding, applied in coatings, optical devices, metal material coating processes, etc., can solve the problems of inability to express gravity, inability to fully characterize cladding layer and molten pool morphology, It is impossible to study the influence of gravity on the rapid prototyping and repair quality of parts, and achieve the effect of simple, direct and accurate characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

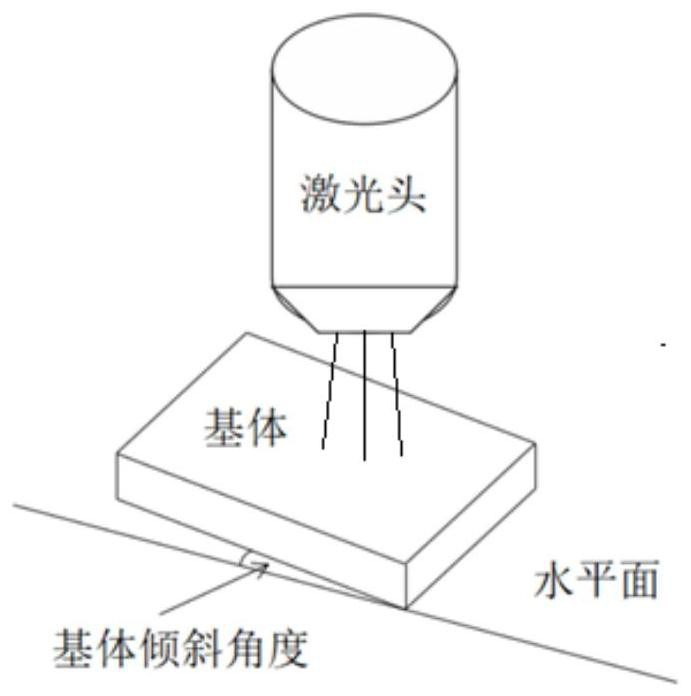

[0021] The base material used in this example is 17CrNiMo6, and the cladding layer material is Ni60. The inclination angle of the substrate is 60°, the laser power is 2000W, the scanning speed is 0.003m / s, and the powder feeding rate is 20r / min. The specific steps of the method are as follows:

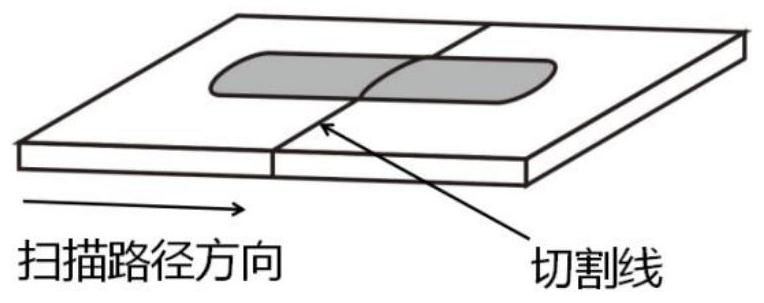

[0022] Step 1 Cut the substrate sample that has been clad

[0023] Use a wire cutting machine to cut the clad substrate sample along the direction perpendicular to the scanning path of the cladding layer, that is, along the figure 2 Cut at the position where the cutting line is marked;

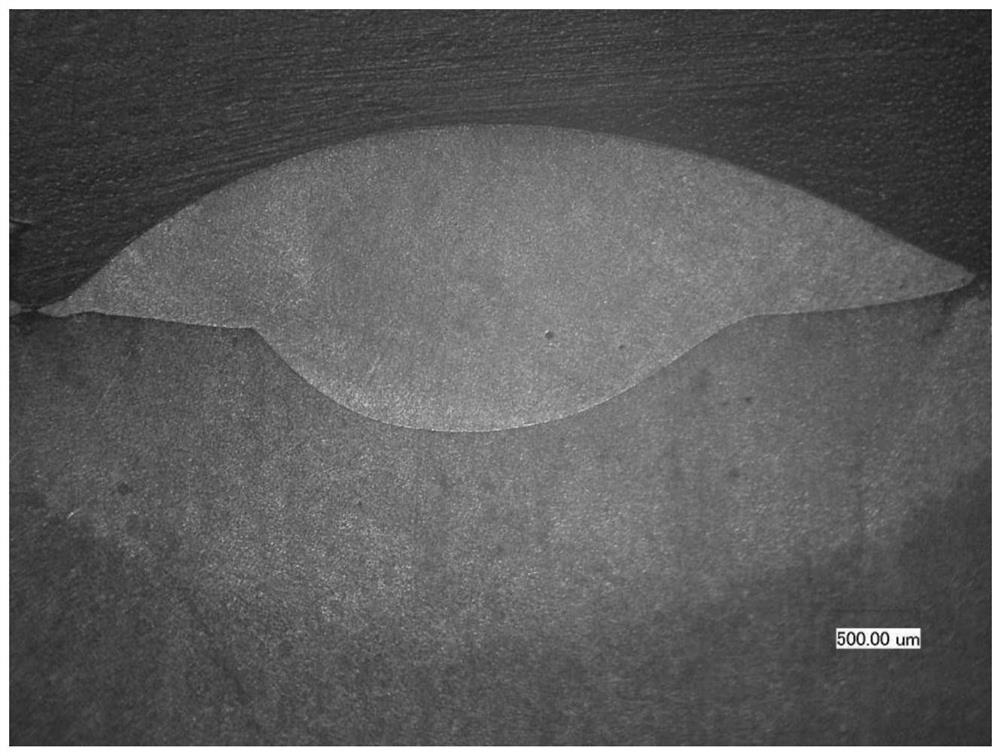

[0024] Step 2 Grinding the cut matrix sample

[0025] Grind one of the cut matrix samples on sandpaper with a particle size of 80, 120, 400, 800, 1500, 2000 and 2500 according to the method for metallographic sample preparation, and then grind the polished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com