Correction method of square resistance in ohmic contact area

An ohmic contact area and ohmic contact technology, applied in the measurement of resistance/reactance/impedance, circuits, electrical components, etc., can solve problems such as large amount of calculation, inability to do approximate processing, and influence of the accuracy of the square resistance value in the ohmic area. The process technology is simple and stable, the test method is fast and convenient, and it is conducive to the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

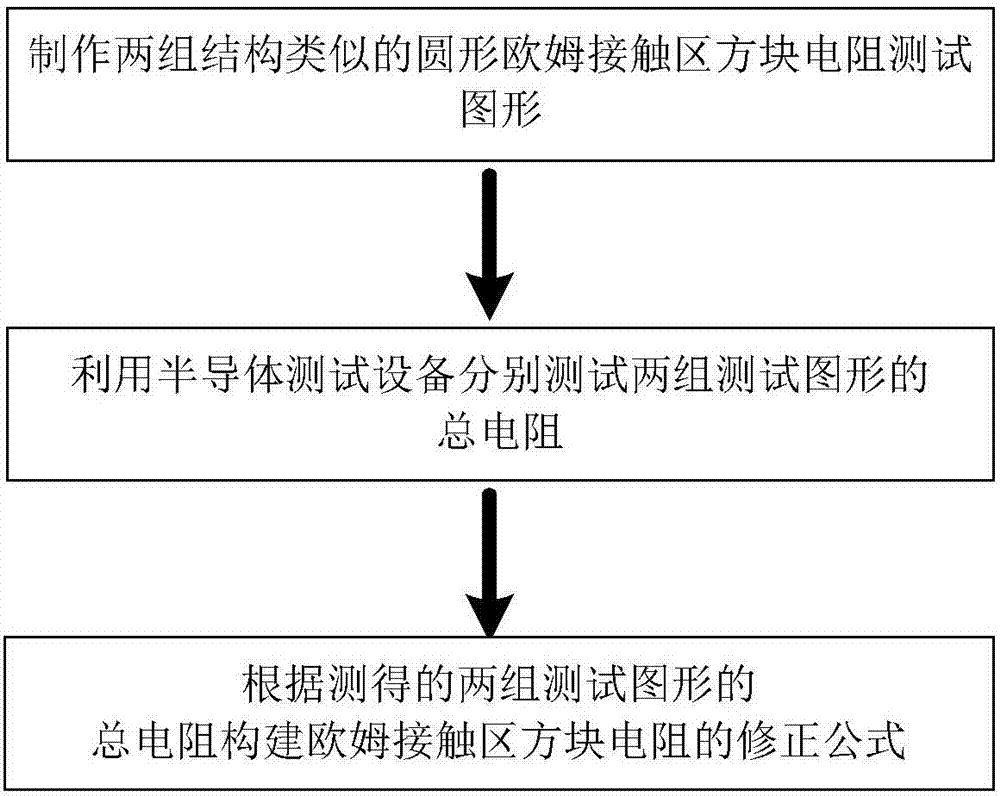

[0033] refer to figure 1 , the implementation steps of the present invention are as follows:

[0034]Step 1, make the test pattern of the square resistance of the ohmic contact area.

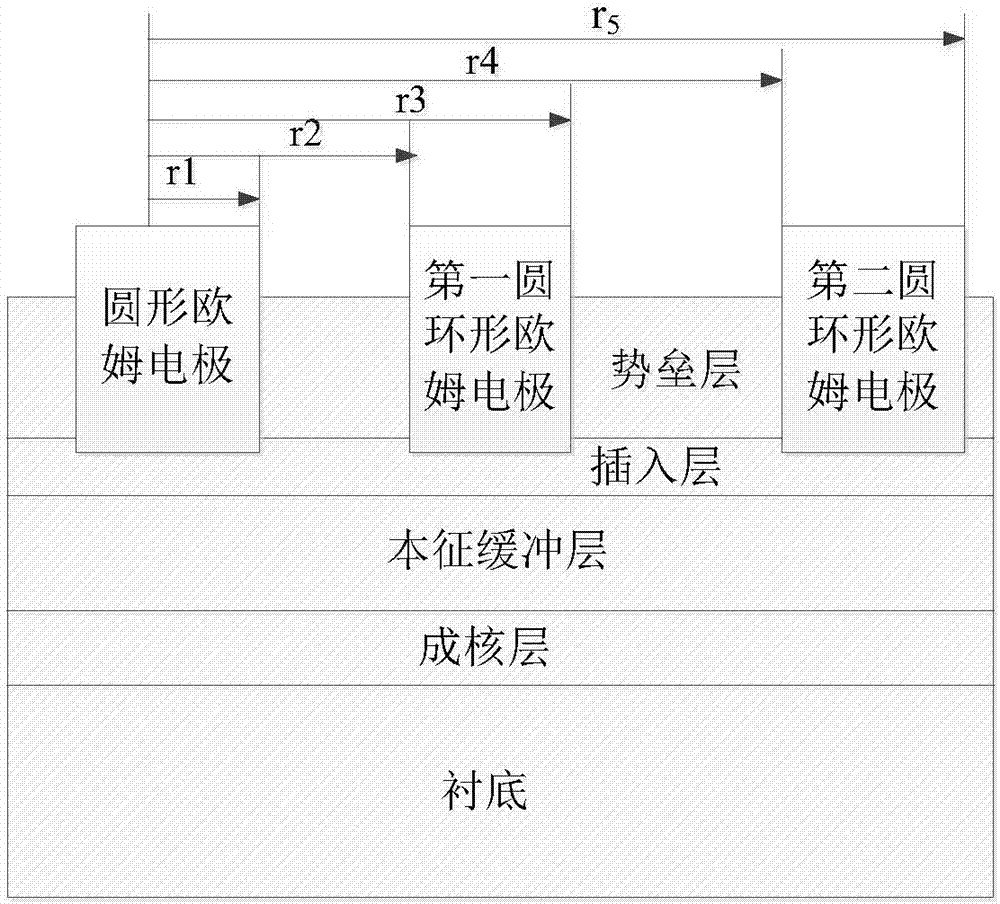

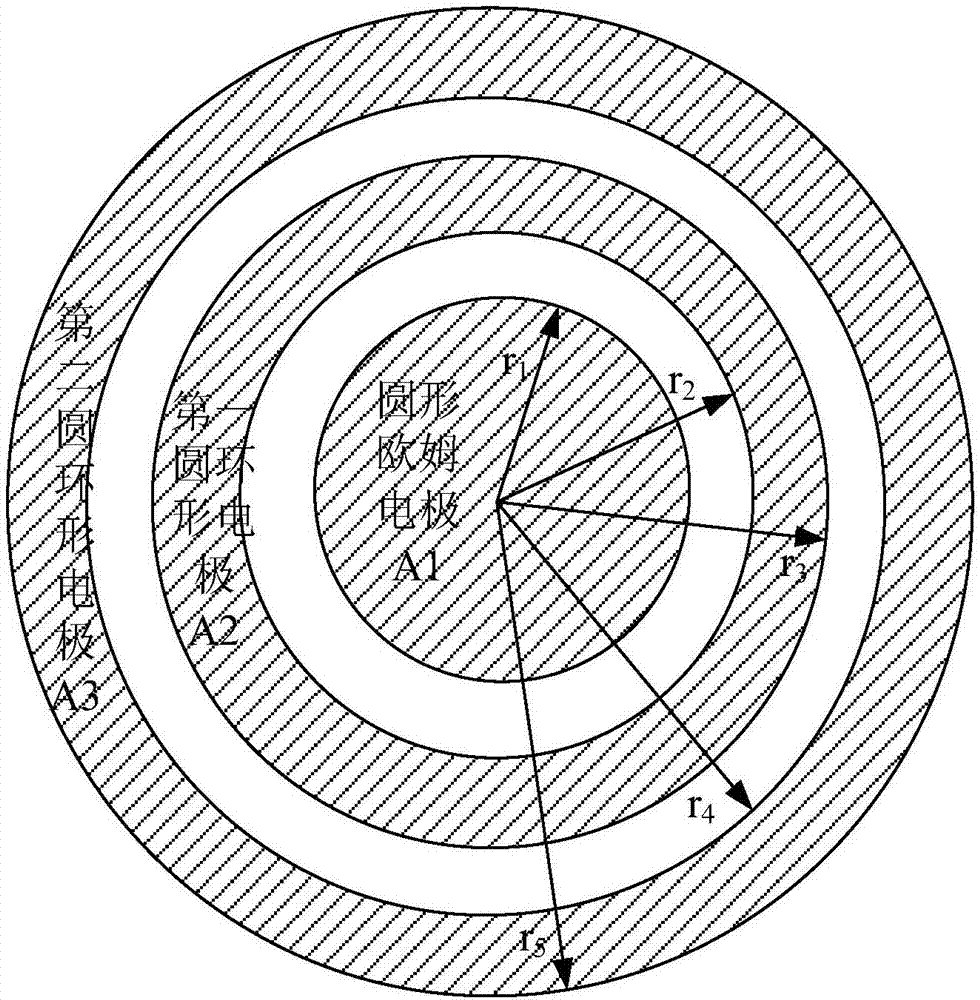

[0035] refer to figure 2 , the specific implementation of this step is as follows:

[0036] 1a) Using the heterojunction epitaxial growth method to grow the substrate layer, nucleation layer, intrinsic buffer layer, insertion layer, and barrier layer sequentially from bottom to top on the substrate; the commonly used substrates are sapphire, silicon, and silicon carbide , diamond and other materials, the nucleation layer and the insertion layer are commonly used aluminum nitride materials, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com