Line-scanning X-ray tube digital imaging detection device

A technology of digital imaging and detection device, applied in the direction of using radiation for material analysis, etc., can solve the problems of low detection efficiency, low detection efficiency, affecting detection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

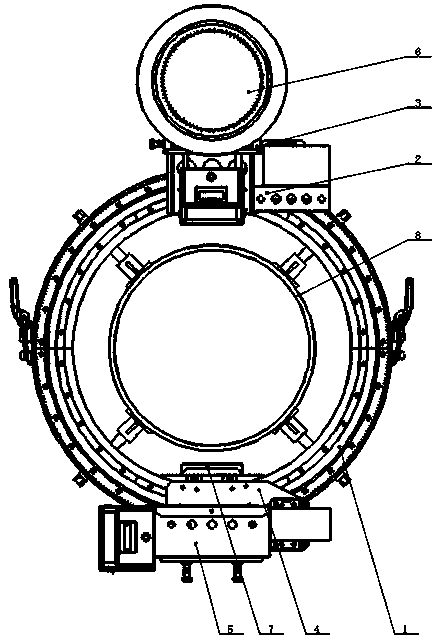

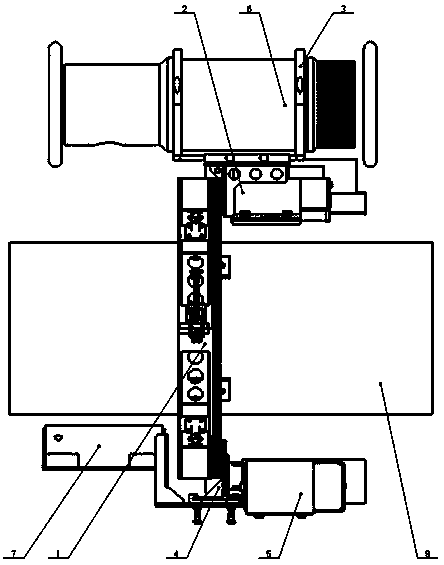

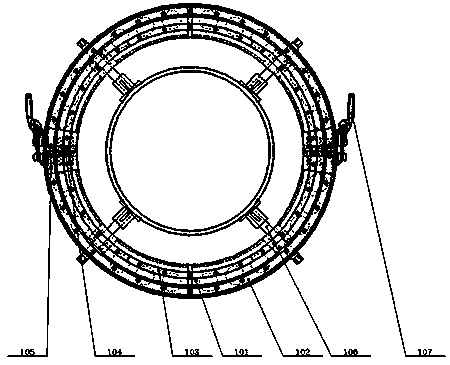

[0029] Such as Figure 1-Figure 12 A line scanning type X-ray pipeline digital imaging detection device is shown, including a detection equipment fixing ring 1, a X-ray machine moving base 2, a X-ray machine fixing device 3, a detector moving base 4, a detector dismounting device 5, a X-ray machine 6, Line array device 7; wherein the testing equipment fixing ring 1 is fixed outside the center position of the butt weld of the steel pipe 8 to be tested, and the X-ray machine moving base 2 is connected with the arc guide rail 103 through the arc guide rail slider 106 and fixed on the testing equipment. On the upper end of the ring 1, the drive gear 1 205 is engaged with the arc rack 102 to complete the drive transmission, and the detector moving base 4 is connected to the arc guide rail 103 through the arc guide rail slider 2 406 and fixed on the detection equipment fixed ring 1 At the lower end, the drive gear 2 405 is engaged with the arc-shaped rack 102 to complete the drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com