Lead storage battery capable of overcoming early capacity attenuation and preparation method thereof

A lead-acid battery and capacity decay technology, applied in the field of lead-acid battery and its preparation to overcome the early capacity decay of lead-calcium alloy batteries, can solve the problems of easy decay of early capacity and the like, and meet the requirements of maintenance-free, reduced migration, and no increase in water loss rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

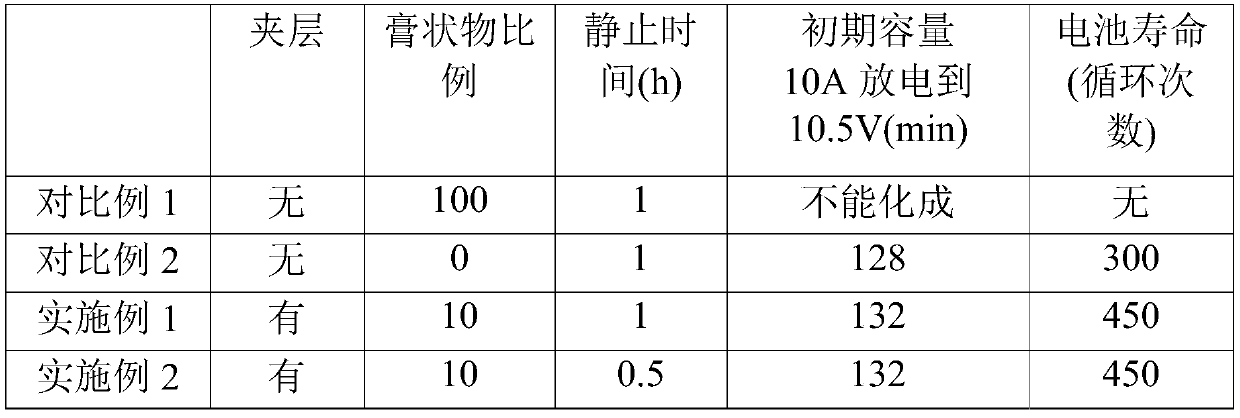

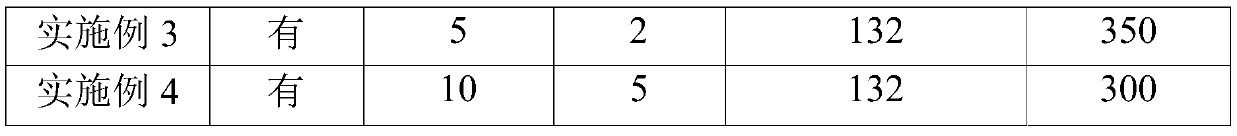

Examples

Embodiment 1

[0036] 1. Preparation of transition layer paste

[0037] Add 100Kg of lead powder, 70g of fiber and 1Kg of Sb to a common paste machine 2 o 3 , dry mix for 5 minutes, add 18Kg of water, stir for 5 minutes after adding water, then add 9.6Kg of 1.4 sulfuric acid, control the speed of acid addition, finish adding within 15 minutes, and stir for 3 minutes after adding acid to form Sb 2 o 3 A paste with a content of about 0.8% and an apparent specific gravity of 3.7.

[0038] 2. Formation of transition layer

[0039] The lead-calcium alloy grid of the 20Ah battery is immersed in the paste for 5 minutes, and the surface of the grid is coated with a brush, and the weight of the paste is controlled to be 10% of the total amount of the paste.

[0040] 3. Production of positive electrode paste

[0041] Add 100Kg of lead powder, 70g of fiber and 0.1Kg of Sb to a common paste machine 2 o 3 and 0.1Kg of SnSO 4 , dry mix for 5 minutes, add 12Kg of water, add water for 5 minutes, the...

Embodiment 2

[0051] 1. Preparation of transition layer paste

[0052] Add 100Kg of lead powder, 70g of fiber and 1Kg of Sb to a common paste machine 2 o 3 , dry mix for 5 minutes, add 18Kg of water, stir for 5 minutes after adding water, then add 9.6Kg of 1.4 sulfuric acid, control the speed of acid addition, finish adding within 15 minutes, and stir for 3 minutes after adding acid to form Sb 2 o 3 A paste with a content of about 0.8% and an apparent specific gravity of 3.7.

[0053] 2. Formation of transition layer

[0054] The lead-calcium alloy grid of the 20Ah battery is immersed in the paste for 5 minutes, and the surface of the grid is coated with a brush, and the content of the paste is controlled at 10% of the total amount of paste.

[0055] 3. Production of positive electrode paste

[0056] Add 100Kg of lead powder, 70g of fiber and 0.1Kg of Sb to a common paste machine 2 o 3 and 0.1Kg of SnSO 4 , dry mix for 5 minutes, add 12Kg of water, add water for 5 minutes, then add ...

Embodiment 3

[0066] 1. Preparation of transition layer paste

[0067] Add 100Kg of lead powder, 70g of fiber and 1Kg of Sb to a common paste machine 2 o 3 , dry mix for 5 minutes, add 18Kg of water, stir for 5 minutes after adding water, then add 9.6Kg of 1.4 sulfuric acid, control the speed of acid addition, finish adding within 15 minutes, and stir for 3 minutes after adding acid to form Sb 2 o 3 A paste with a content of about 0.8% and an apparent specific gravity of 3.7.

[0068] 2. Formation of transition layer

[0069] Immerse the lead-calcium alloy grid of a 20Ah battery in the paste for 5 minutes, and use a brush to coat the surface of the grid, and control the weight of the paste to 5% of the total amount of the paste .

[0070] 3. Production of positive electrode paste

[0071] Add 100Kg of lead powder, 70g of fiber and 0.1Kg of Sb to a common paste machine 2 o 3 and 0.1Kg of SnSO 4 , dry mix for 5 minutes, add 12Kg of water, add water for 5 minutes, then add 10Kg of 1.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com