A kind of preparation method and application of lead storage battery positive plate

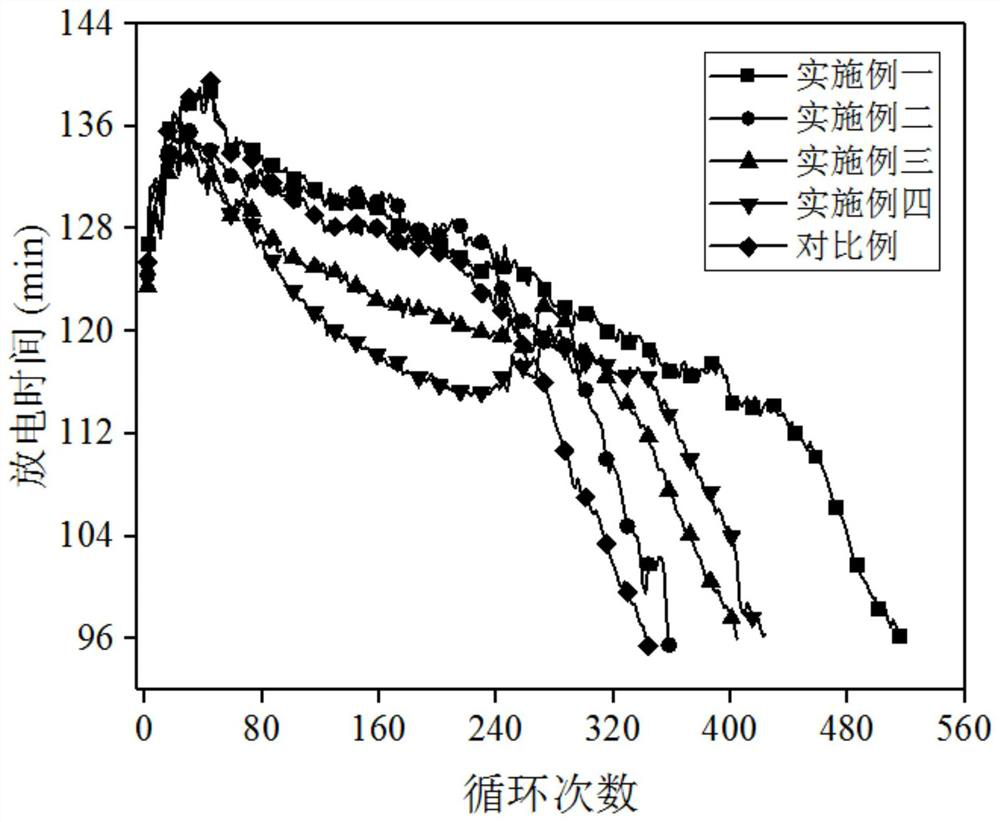

A lead-acid battery, positive plate technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc., can solve the problems of rapid battery capacity decay, short cycle life, etc., to avoid capacity decay, prolong cycle life, Solve the effect of poor battery discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the lead storage battery positive plate of the present embodiment comprises the steps of:

[0032] (1) Clean the 6-DZF-20 positive plate with detergent to remove impurities such as saponified oil on the plate, and then wash the detergent with pure water.

[0033] (2) Pretreatment: Immerse the positive plate in the pretreatment solution and charge it with a current density of 0.02mA / cm 2 , the charging time is 30h, the charging temperature is 25±5℃, then take out the positive plate and rinse the positive plate with a large amount of pure water, and dry it;

[0034] The pretreatment liquid contains NaClO 4 , SbCl 3 and H 2 o 2 sulfuric acid solution, where NaClO 4 The mass concentration is 0.7%, SbCl 3 The mass concentration is 0.2%, H 2 o 2 The mass concentration is 1%, the mass concentration of sulfuric acid is 4%, and the temperature of the pretreatment liquid is 25±2°C.

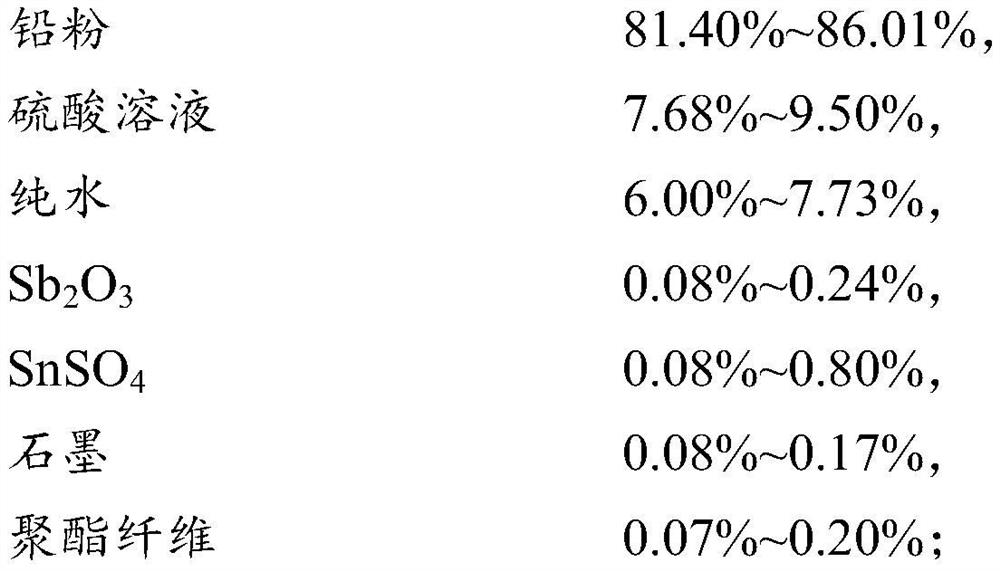

[0035] (3) Coating lead paste on the surface of the pretreated...

Embodiment 2

[0043] The preparation method of the lead storage battery positive plate of the present embodiment comprises the steps of:

[0044] (1) Clean the 6-DZF-20 positive plate with detergent to remove impurities such as saponified oil on the plate, and then wash the detergent with pure water.

[0045] (2) Pretreatment: Immerse the positive plate in the pretreatment solution and charge it with a current density of 0.02mA / cm 2 , the charging time is 30h, the charging temperature is 25±5℃, then take out the positive plate and rinse the positive plate with a large amount of pure water, and dry it;

[0046] The pretreatment liquid contains NaClO 4 sulfuric acid solution, where NaClO 4 The mass concentration is 0.4%, the mass concentration of sulfuric acid is 4%, and the temperature of the pretreatment liquid is 25±2°C.

[0047] (3) Coating lead paste on the surface of the pretreated positive plate.

[0048] Taking the total weight of raw materials as 100%, the raw material compositio...

Embodiment 3

[0054] The preparation method of the lead storage battery positive plate of the present embodiment comprises the steps of:

[0055] (1) Clean the 6-DZF-20 positive plate with detergent to remove impurities such as saponified oil on the plate, and then wash the detergent with pure water.

[0056] (2) Pretreatment: Immerse the positive plate in the pretreatment solution and charge it with a current density of 0.02mA / cm 2 , the charging time is 30h, the charging temperature is 25±5℃, then take out the positive plate and rinse the positive plate with a large amount of pure water, and dry it;

[0057] The pretreatment liquid contains NaClO 4 , SbCl 3 and H 2 o 2 sulfuric acid solution, where NaClO 4 The mass concentration is 0.7%, SbCl 3 The mass concentration is 0.05%, H 2 o 2 The mass concentration is 0.2%, the mass concentration of sulfuric acid is 4%, and the temperature of the pretreatment liquid is 25±2°C.

[0058] (3) Coating lead paste on the surface of the pretrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com