Linear motor

A technology of linear motors and electromagnetic wires, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced service life, affecting the vibration intensity of linear motors, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

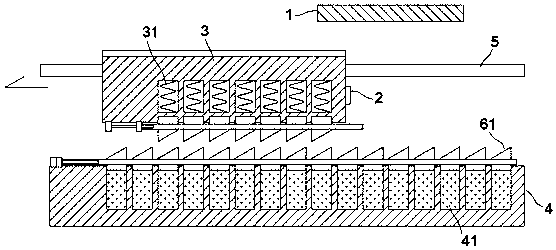

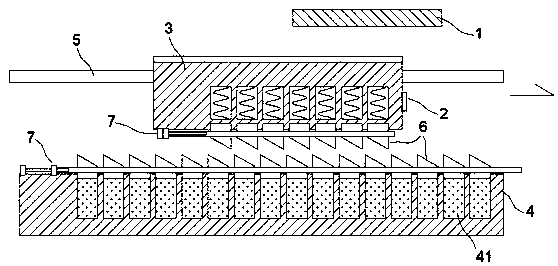

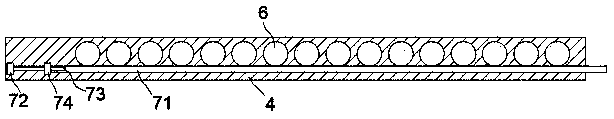

[0019] exist figure 1 , figure 2 , image 3 In the shown embodiment, the linear motor includes a control element 1, a positioning element 2, a moving plate 3, a fixed plate 4 and a fixed slide rail 5, the moving plate 3 is slidably arranged on the fixed slide rail 5, and the fixed plate 4 and the moving plate The plates 3 are arranged parallel to each other; permanent magnets 41 are arranged in an equidistant array on the fixed plate 4 , and an electromagnetic wire barrel 31 is arranged inside the moving plate 3 , and the electromagnetic wire barrel 31 is electrically connected to the control element 1 , the positioning element 2 is electrically connected to the control element 1, and the positioning element 2, the electromagnetic wire barrel 31, and the control element 1 are powered by a power supply;

[0020] The magnetic pole connection direction of the permanent magnet 41 is perpendicular to the plate surface of the moving plate 3, and the magnetic pole arrangement orie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap