Conductive MOF modified carbon fiber paper intercalation material for lithium-sulfur battery

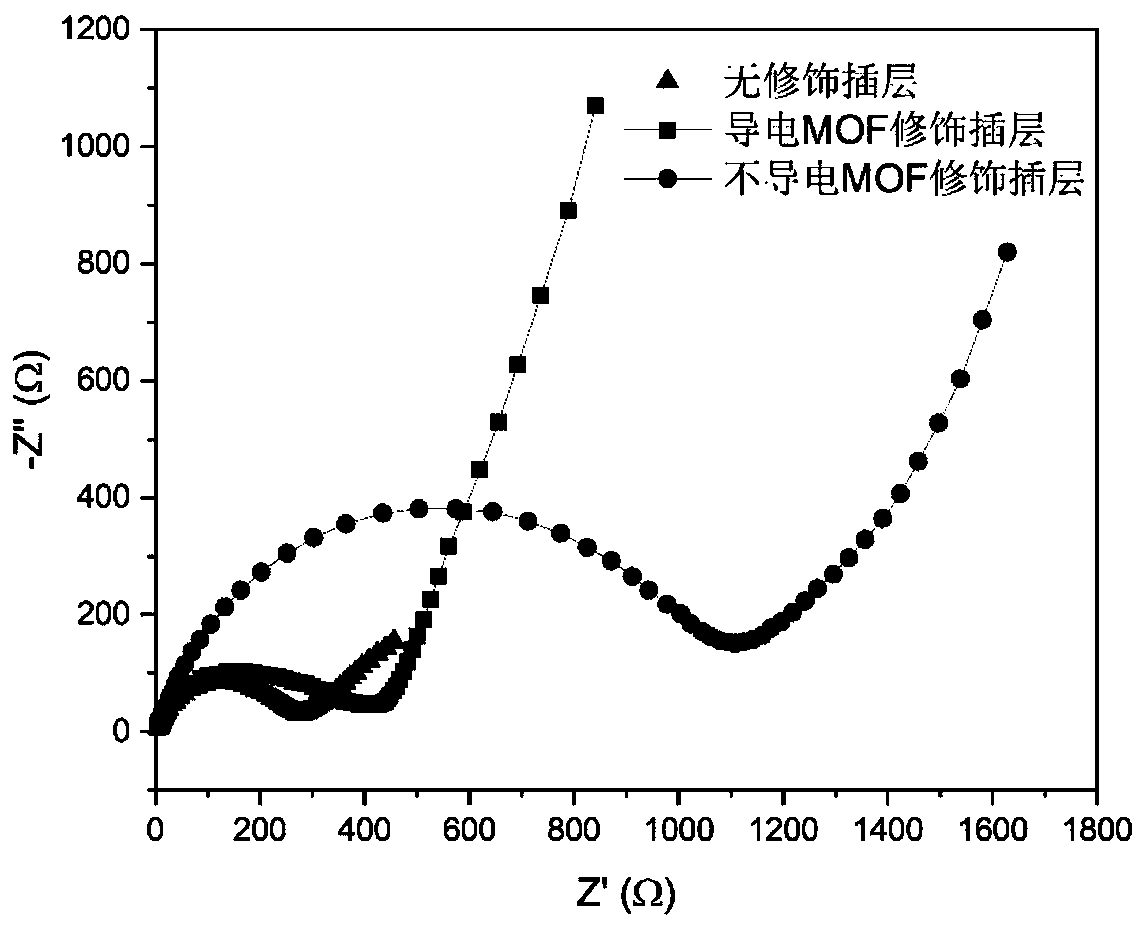

A carbon fiber paper, lithium-sulfur battery technology, applied in lithium batteries, battery electrodes, fiber raw material processing and other directions, can solve the problems of low conductivity, low efficiency of lithium polysulfide shuttle inhibition, poor cycle stability of lithium-sulfur batteries, etc. The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a second typical embodiment of the present invention, the preparation method of the carbon fiber paper material modified by the conductive MOF is provided, the method may further comprise the steps:

[0037] Pretreatment of carbon fiber paper: hydrophilic treatment of carbon fiber paper materials;

[0038] Preparation grown with Co 3 (HITP) 2 carbon fiber paper: divalent cobalt ion Co 2+ Coordinate with hexaaminotriphenylene (HITP) on the surface of hydrophilic carbon fiber paper and grow in situ;

[0039] Removal of structural impurities: removal of Co that did not participate in the reaction 2+ , ligand HITP, solvent DMF molecules and free MOF molecules on the surface of carbon fiber paper.

[0040] In the present invention, there can be many kinds of hydrophilic treatment methods for carbon fibers, but in order to better maintain the integrity of carbon fibers and better improve the hydrophilic performance-uniformity, in some embodiments of the present inventi...

Embodiment 1

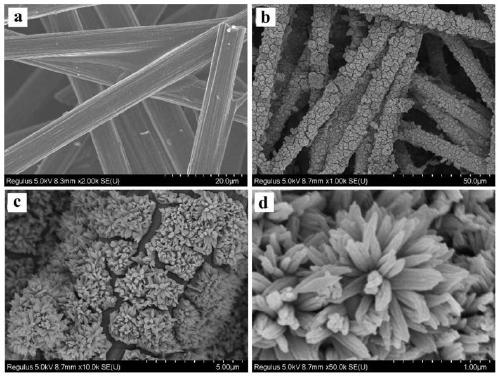

[0062] A flower-like Co 3 (HITP) 2 carbon fiber paper material, divalent cobalt ion Co 2+ Coordinate with HITP on the surface of hydrophilic carbon fiber paper and grow in situ.

[0063] The preparation method of this material comprises the following steps:

[0064] (1) Hydrophilic treatment of carbon fiber paper: cut commercial carbon fiber paper (source: physical and chemical (Hong Kong) Co., Ltd. model is N0S1005 carbon fiber paper) with a microtome and store it for later use (16mm in diameter), take deionized water and acetone respectively 10ml each of isopropanol and mix well in a 50ml beaker. Take a certain number of carbon fiber paper slices, make them completely submerged in the mixed solution, seal the beaker with paraffin parafilm and ultrasonically treat it for 60 minutes. After treatment, take it out and ultrasonically clean it with deionized water for 3 times, each time for 5 minutes, and then use absolute ethanol to ultrasonically clean it for 3 times, each t...

Embodiment 2

[0088] A flower-like Co 3 (HITP) 2 carbon fiber paper material, which is prepared by the following method:

[0089] (1) Hydrophilic treatment of carbon fiber paper: cut commercial carbon fiber paper with a microtome and store it for later use (16 mm in diameter), weigh 12 ml each of deionized water, acetone, and isopropanol, and mix them evenly in a 50 ml beaker. Take a certain number of carbon fiber paper slices, make them completely submerged in the mixture, seal the beaker with parafilm and ultrasonicate for 75 minutes. After treatment, take it out and ultrasonically clean it with deionized water for 3 times, each time for 4 minutes, and then use absolute ethanol to ultrasonically clean it for 3 times, each time for 4 minutes. The carbon fiber paper was transferred to a glass dish lined with filter paper, and dried in an oven at 100°C for 13 hours.

[0090] (2) Prepare and grow flower-like Co 3 (HITP) 2 carbon fiber paper: Use a pipette gun to pipette 500 μL each of DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com