Self-propelled straw compressor

A compressor and self-propelled technology, applied in the field of agricultural machinery, can solve the problems of waste of manpower and material resources, high soil content in the product, increase the cost of briquetting, etc., and achieve the effect of being beneficial to molding, flexible driving and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

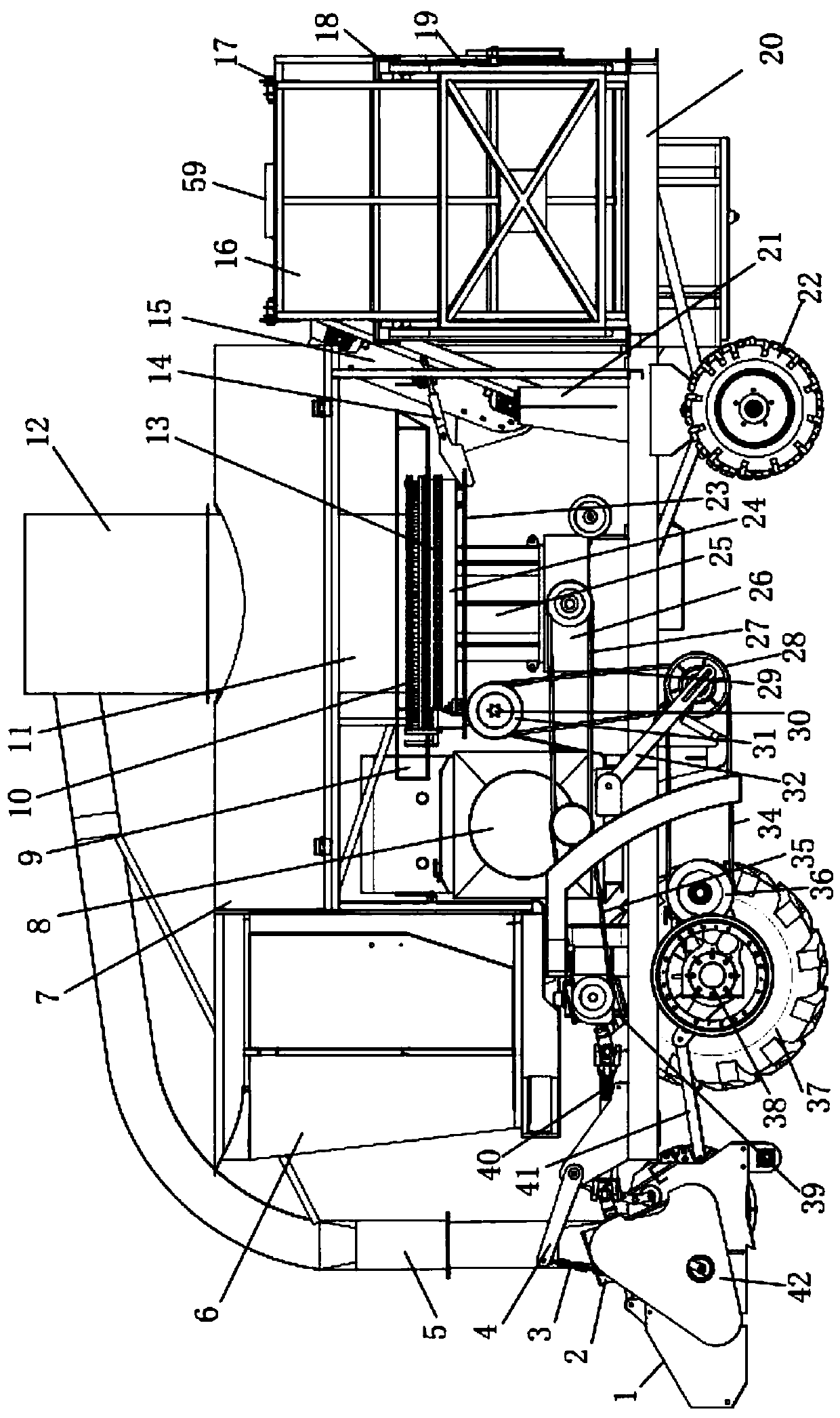

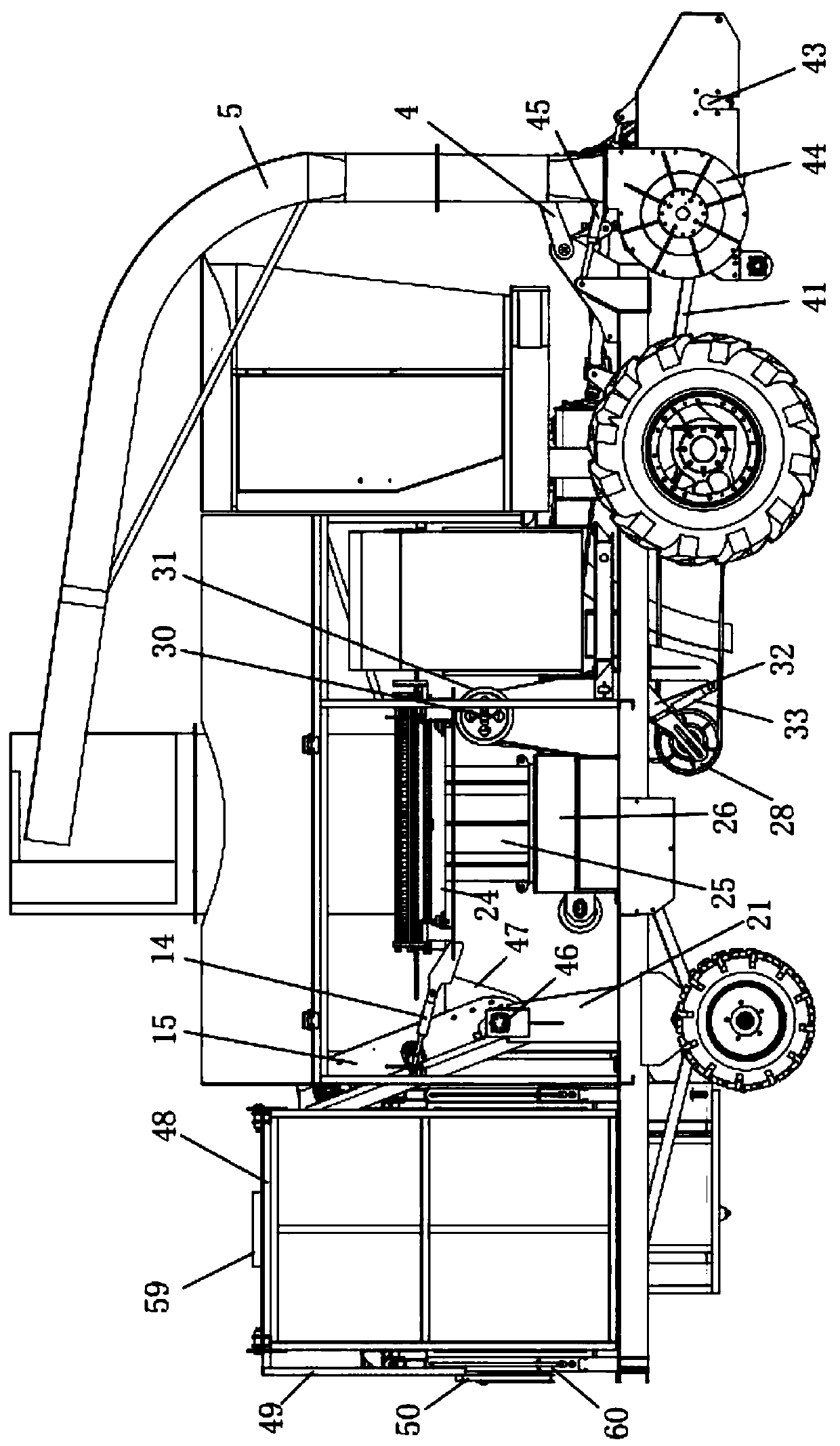

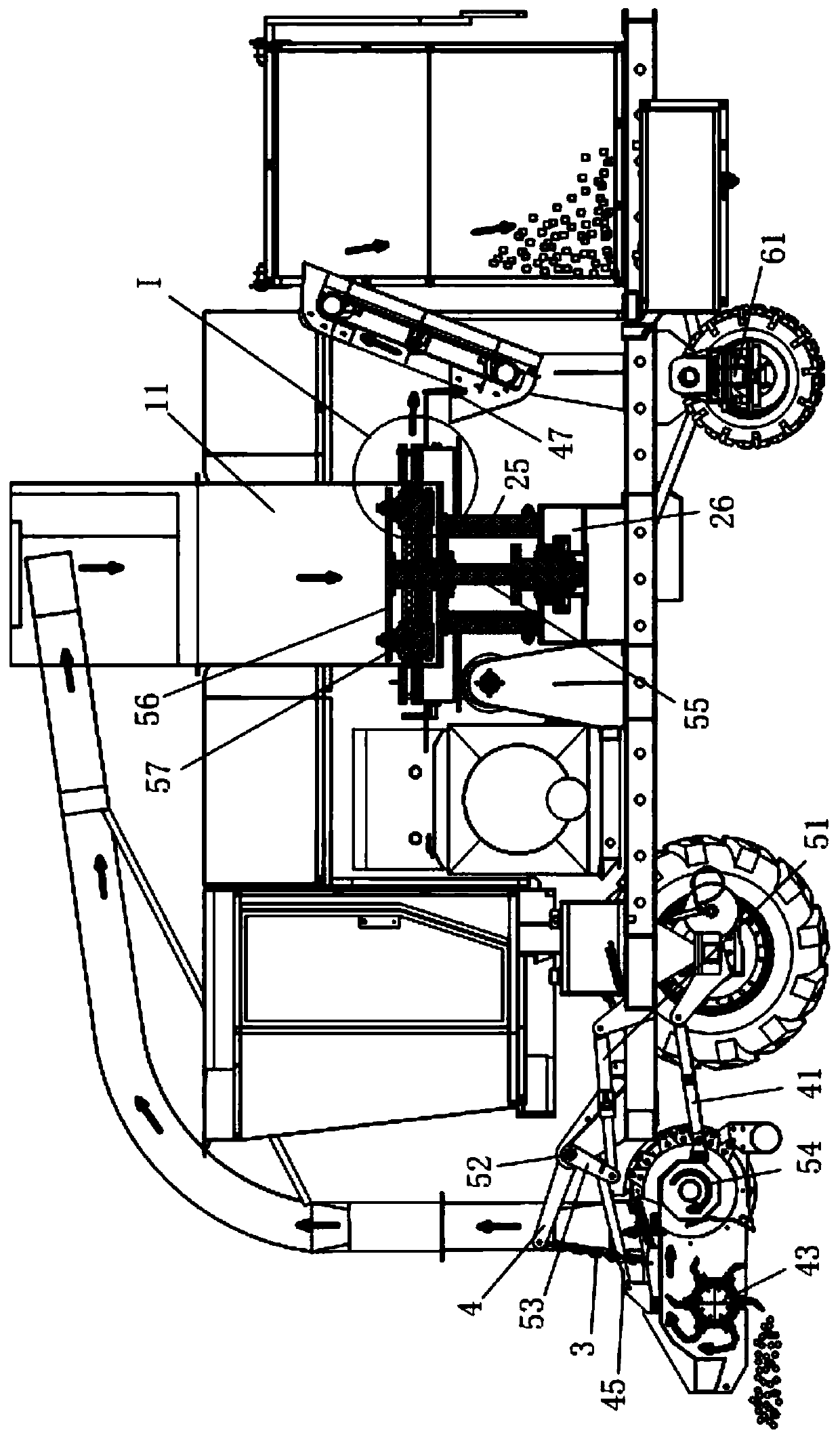

[0033] Such as Figure 1-Figure 8 As shown, the self-propelled straw compressor includes a motor vehicle body 20 with a walking wheel set, a cab 6 mounted on the motor vehicle body 20, a picking system, a compression system, a product storage bin and a transmission system.

[0034] Wherein, the walking wheel set is made up of a pair of walking front wheels 37 and a pair of steering rear wheels 22 whose diameter is smaller than the walking front wheels 37 and utilizing the steering rear axle 61 to install. A material hoist is provided between the discharge end of the compression system and the feeding port of the product storage bin.

[0035] The transmission system is composed of a diesel engine power assembly 8 fixed on the motor vehicle body 20, a pick-up drive assembly, a compression drive assembly and a travel drive assembly respectively connected to the power output end of the diesel engine power assembly 8. The drive assembly for picking up is composed of a transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com