Granular premixed feed for laying hens and production process of granular premixed feed for laying hens

A premixed feed and granule technology, which is applied in the shaping or processing of animal feed, animal feed, additional food elements, etc., can solve the problems of poor mixing uniformity, vitamin destruction, and nutrient loss, so as to reduce oxidation and increase production. Egg rate and egg weight, the effect of maintaining ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

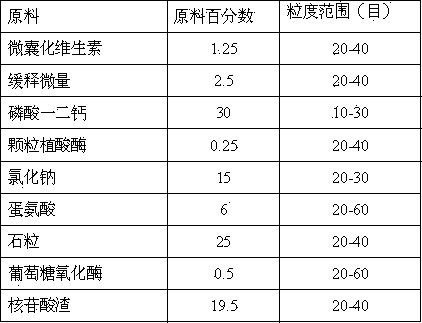

[0031] The formula of granular premixed feed for laying hens is as follows:

[0032]

[0033] The mixing method is as follows:

[0034] (1) Sustained-release trace, methionine, stone grains and nucleotide slag are automatically weighed by computer in the warehouse, and they are ready for use;

[0035] (2) Microencapsulated vitamins, granular phytase and glucose oxidase are pre-mixed after manual weighing, and mixed evenly;

[0036] (3) Put the raw materials of step (1) and step (2) into a twin-shaft paddle stainless steel mixer and mix for 120 seconds, pack it, and get it.

[0037] The addition amount of the granular premixed feed for laying hens provided in this example is 1% during use.

Embodiment 2

[0039] The formula of granular premixed feed for laying hens is as follows:

[0040]

[0041] The mixing method is as follows:

[0042] (1) Sustained-release trace, monocalcium phosphate, sodium chloride, methionine, stone grains and nucleotide slag are automatically weighed in the warehouse by computer, and they are ready for use;

[0043] (2) Microencapsulated vitamins, granular phytase and glucose oxidase are pre-mixed after manual weighing, and mixed evenly;

[0044] (3) Put the raw materials of step (1) and step (2) into a twin-shaft paddle stainless steel mixer and mix for 120 seconds, pack it, and get it.

[0045] The addition amount of the granular premixed feed for laying hens provided in this example is 2% during use.

Embodiment 3

[0047] The formula of granular premixed feed for laying hens is as follows:

[0048]

[0049] The mixing method is as follows:

[0050] (1) Sustained-release trace, monocalcium phosphate, sodium chloride, methionine, stone grains and nucleotide slag are automatically weighed in the warehouse by computer, and they are ready for use;

[0051] (2) Microencapsulated vitamins, granular phytase and glucose oxidase are pre-mixed after manual weighing, and mixed evenly;

[0052] (3) Put the raw materials of step (1) and step (2) into a twin-shaft paddle stainless steel mixer and mix for 120 seconds, pack it, and get it.

[0053] The addition amount of the granular premixed feed for laying hens provided in this example is 3% during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com