System and method of temperature-ultrasonic synergistic regulation of dissolved hydrogen content in beverage

A beverage and hydrogen dissolving technology, which is applied in food ultrasonic treatment, gas-containing food ingredients, food science, etc., can solve the problems of waste, hydrogen cost and energy consumption, etc., and achieve the effect of large hydrogen dissolution and good product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

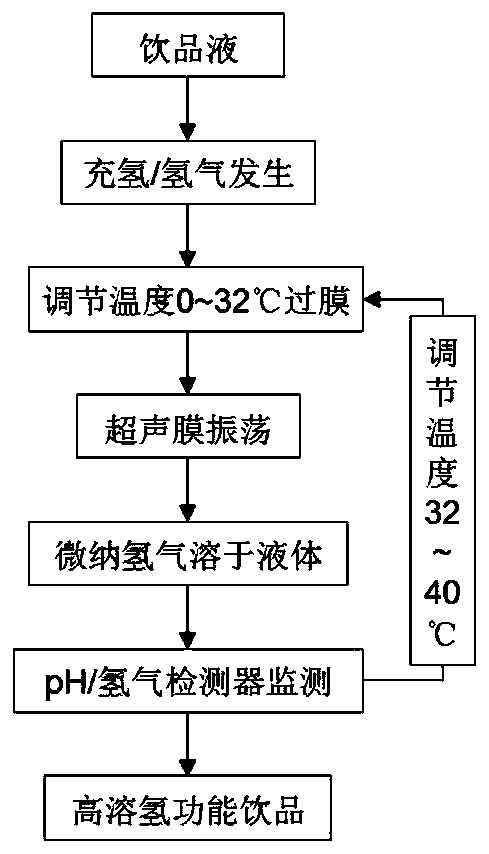

Method used

Image

Examples

Embodiment 1

[0017] Set the temperature-ultrasonic cooperative adjustment system for the hydrogen dissolution of beverages in the degassed fruit juice, turn on the hydrogen generator, reduce the temperature in the degassed juice to 20°C, turn on the ultrasound, and control its vertical diffusion frequency to 600KHz, the temperature The pores of the responsive microporous membrane expand and oscillate to release micro-nano hydrogen gas, which dissolves in the fruit juice. When the juice reaches 3% hydrogen dissolution, raise the temperature of the system to 32°C, turn off the ultrasonic and hydrogen generators, and export the hydrogen-rich juice for filling.

[0018] Add the hydrophobic dye rhodamine 6G to the hydrogen-rich juice prepared above to reversely mark hydrogen gas, and observe the distribution under a super-resolution confocal laser microscope; dope nano-fluorescent cadmium sulfide quantum dots in the bulk phase of the hydrogen-rich juice for further observation distributed. The...

Embodiment 2

[0020] Set the temperature-ultrasonic cooperative adjustment system for the hydrogen dissolution of drinks in the degassed milk, turn on the hydrogen generator, reduce the temperature in the degassed milk to 10°C, turn on the ultrasound, and control its vertical diffusion frequency to 1MHz, the temperature The pores of the responsive microporous membrane expand and oscillate to release micro-nano hydrogen gas, which dissolves in the milk. When the degree of 4% hydrogen dissolution in the milk is reached, the system temperature is raised to 32°C, the ultrasonic and hydrogen generators are turned off, and the hydrogen-rich milk is exported for filling.

[0021] The hydrogen-rich milk prepared above was added to the hydrophobic dye rhodamine 6G to reversely mark the hydrogen gas, and the distribution was observed under a super-resolution confocal laser microscope; nano-fluorescent cadmium sulfide quantum dots were doped in the bulk phase of the hydrogen-rich milk for further obser...

Embodiment 3

[0023] Set the temperature-ultrasonic cooperative adjustment system for the hydrogen dissolution of beverages in degassed water, open the hydrogen filling catheter, lower the temperature in the degassed water to 0°C, turn on the ultrasound, and control its longitudinal diffusion frequency to 1MHz, temperature-responsive type The pores of the microporous membrane expand and oscillate to release micro-nano hydrogen gas, which dissolves in water. When the water reaches 6% hydrogen dissolving level, raise the system temperature to 32°C, turn off the ultrasound and hydrogen charging conduit, and export the hydrogen-rich water for filling.

[0024] Add the hydrophobic dye Rhodamine 6G to the hydrogen-rich water prepared above to reversely mark the hydrogen gas, and observe the distribution under the ultra-high resolution confocal laser microscope; dope nano-fluorescent cadmium sulfide quantum dots in the hydrogen-rich water phase, and further observe the distribution . The results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com