A kind of technological method of producing clean diesel oil

A process method and diesel technology, which are applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment and other directions, can solve the problems of increasing the investment cost of the reactor, and achieve the effects of improving the hydrogen dissolving capacity, good technical effect and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

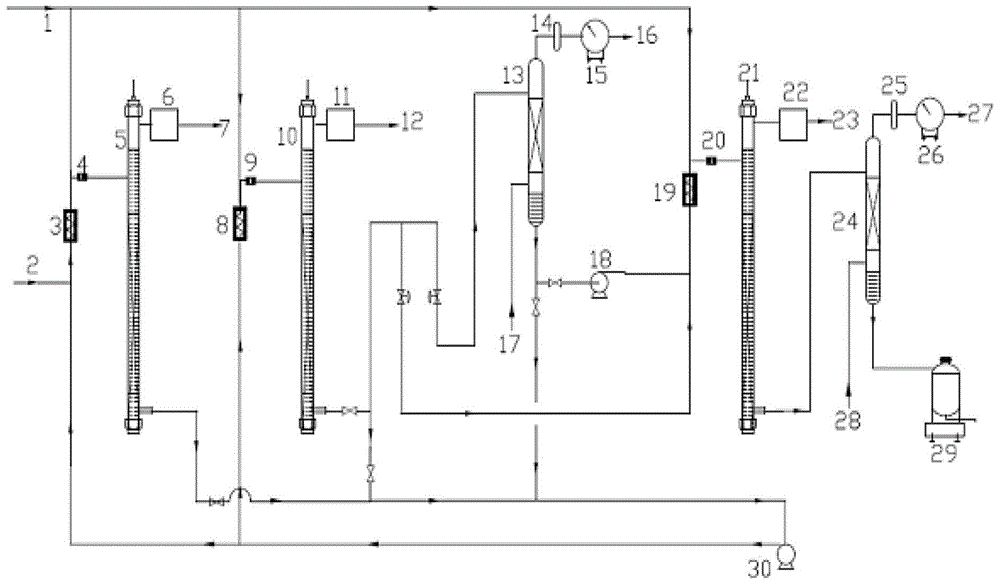

Method used

Image

Examples

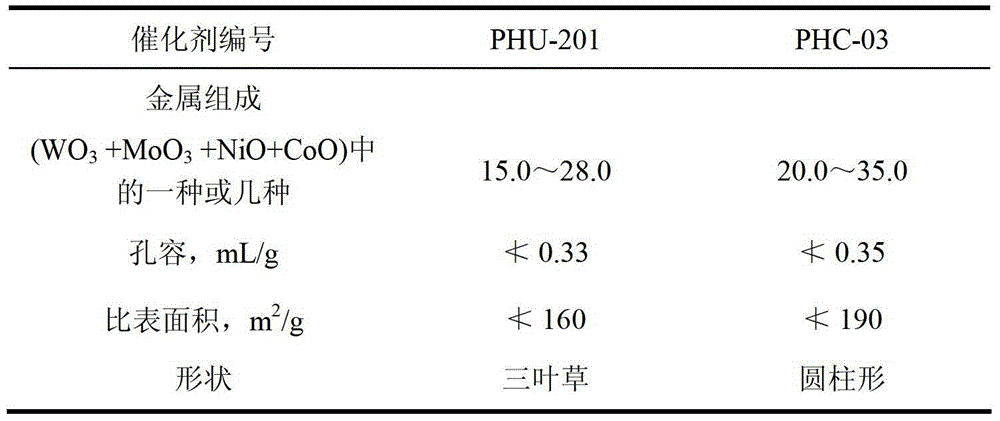

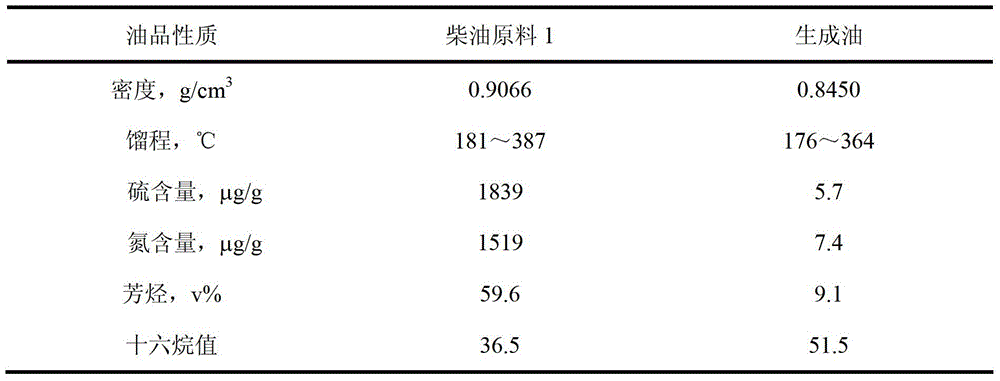

Embodiment 1

[0038] The mixed diesel raw material 1 passes through the heating furnace to reach the required temperature and fully mixes and dissolves the hydrogen in the gas-liquid mixer, then enters the first hydrogenation reactor. The reaction conditions are: reaction system pressure 7.5MPa, reaction temperature 350℃, converted to hydrogen The volume ratio is 200:1. Part of the effluent enters the circulation pipeline and is circulated to the first and second reverse inlets through the liquid circulation pump. The circulation ratio is 1:1, and part of it directly enters the second hydrogenation reactor. The reaction conditions are: reaction system pressure 7.5MPa, reaction temperature 350°C, converted hydrogen to oil volume ratio is 200:1, part of the effluent enters the circulation pipeline and circulates to the first and second reverse inlets through the liquid circulation pump, the circulation ratio is 1:1, and part of it enters the first separator Carry out gas-liquid separation, the...

Embodiment 2

[0041] The mixed diesel raw material 2 goes through the heating furnace to reach the required temperature and fully mixes and dissolves the hydrogen in the gas-liquid mixer, and then enters the first hydrogenation reactor. The volume ratio is 210:1. Part of the effluent enters the circulation pipeline and is circulated to the first and second reverse inlets through the liquid circulation pump. The circulation ratio is 1:1, and part of it directly enters the second hydrogenation reactor. The reaction conditions are: reaction system pressure 7.5MPa, reaction temperature 355℃, converted hydrogen to oil volume ratio is 210:1, part of the effluent enters the circulation pipeline and circulates to the first and second reverse inlets through the liquid circulation pump, the circulation ratio is 1:1, and part of it enters the first separator Carry out gas-liquid separation, the separated liquid effluent enters the third reactor, the reaction conditions are: the reaction system pressure...

Embodiment 3

[0044] The mixed diesel raw material 3 passes through the heating furnace to reach the required temperature and fully mixes and dissolves hydrogen in the gas-liquid mixer before entering the first hydrogenation reactor. The reaction conditions are: reaction system pressure 7.5MPa, reaction temperature 360°C, converted to hydrogen oil The volume ratio is 225:1. Part of the effluent enters the circulation pipeline and is circulated to the first and second reverse inlets through the liquid circulation pump. The circulation ratio is 2:1, and part of it directly enters the second hydrogenation reactor. The reaction conditions are: reaction system pressure 7.5MPa, reaction temperature 360°C, converted hydrogen to oil volume ratio is 225:1, part of the effluent enters the circulation pipeline and circulates to the first and second reverse inlets through the liquid circulation pump, the circulation ratio is 2:1, and part of it enters the first separator Carry out gas-liquid separation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com