Calibration method for joint transmission ratio error of industrial tandem robot

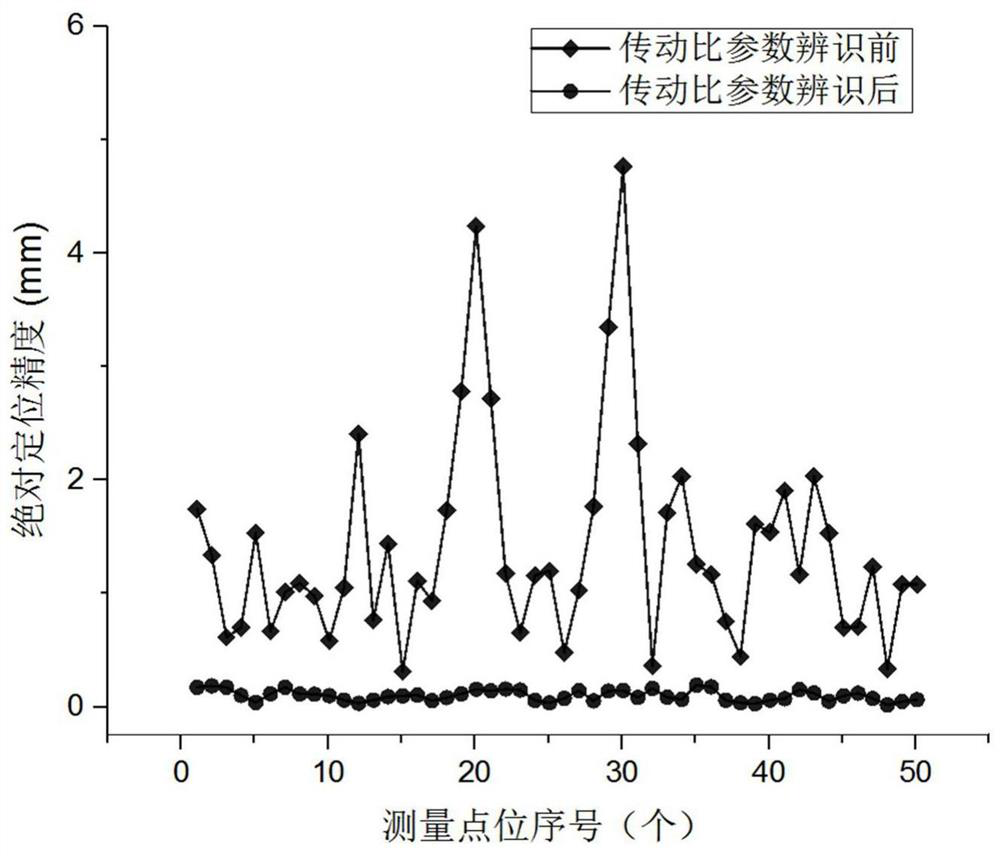

A technology of error calibration and robotics, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of cumbersome identification operations and poor accuracy, achieve high calibration accuracy, fast speed, and improve the effect of absolute positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

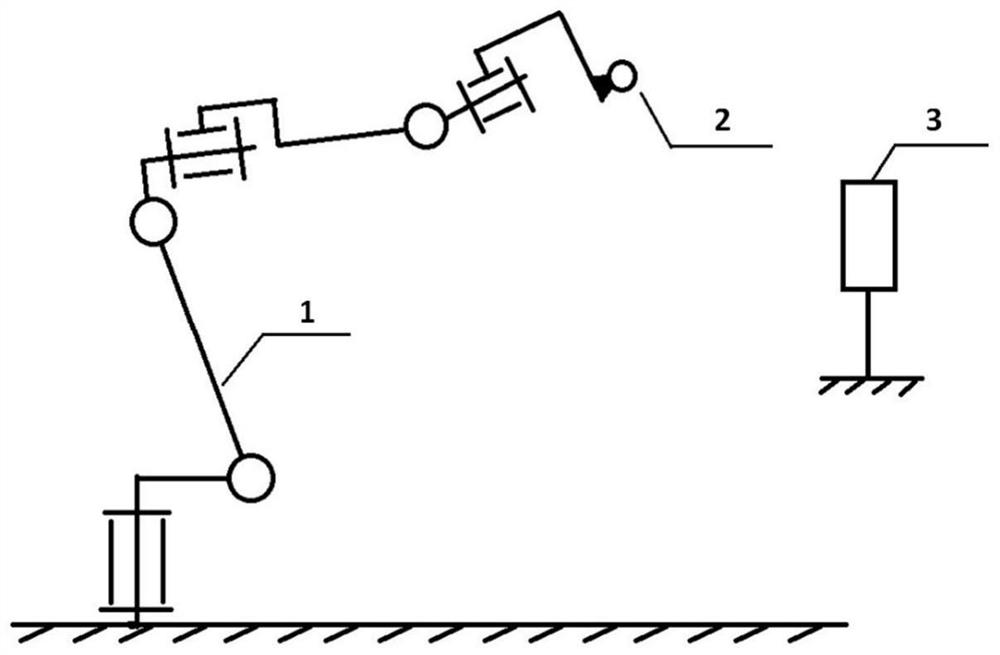

[0048] Such as figure 1 , figure 2 The illustrated embodiment is a joint transmission ratio error calibration method of an industrial tandem robot, including an industrial tandem robot 1, a robot controller, a computer, a laser tracker 3 and a tooling for installing a laser target 2; an industrial tandem robot and a robot controller Data connection, the computer is respectively connected to the robot controller and the laser tracker data; the tooling for installing the laser target is fixedly connected to the end of the robot; including the following steps:

[0049] Step 100, the robot runs to m positions in the flexible workspace

[0050] According to GB / T12642, select any m position points in the cube in the flexible working space of the industrial robot, and the robot controller controls the end of the robot to reach the selected m position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com