Normal-temperature curing flexibility epoxy resin waterproof binder for roads and bridges and preparation method of normal-temperature curing flexibility epoxy resin waterproof binder

An epoxy resin, curing technology at room temperature, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of environment and construction personnel damage, brittle cured product, and reduce the viscosity of the mixture, so as to improve flexibility, Inexpensive, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail through the following examples.

[0044] For the preparation method of A component of high-performance room temperature curing epoxy resin waterproof bonding material for road and bridge is as follows:

[0045] Heat the epoxy resin to 70°C, slowly add the toughening agent a after reaching the predetermined temperature, and keep stirring for 10 minutes after the addition of the toughening agent a. When the temperature drops to 50°C, add the diluent, stir for 5 minutes, and then ultrasonically remove the air bubbles in the 50°C environment for 20 minutes to facilitate subsequent operations. After cooling to room temperature, you can get the room temperature curing flexible epoxy resin waterproof adhesive for road bridges. A component.

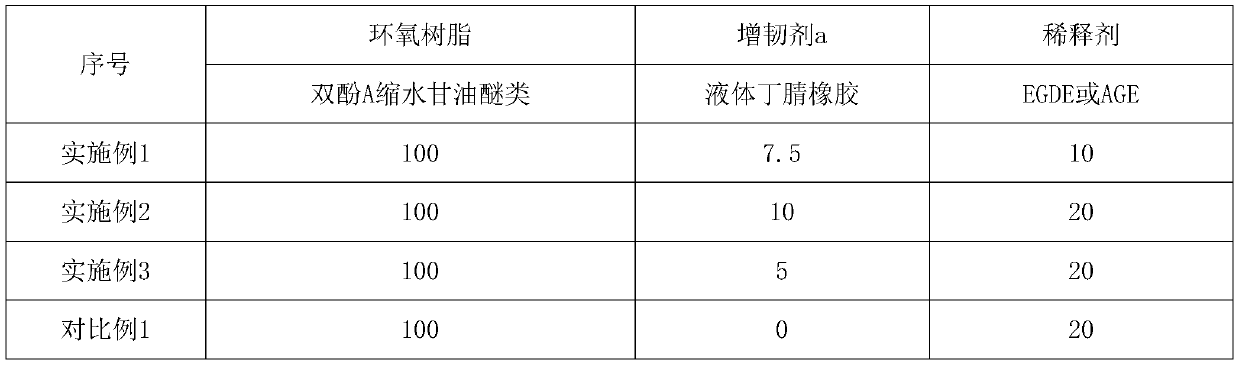

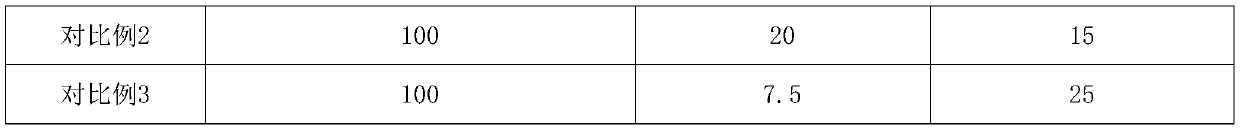

[0046] Through the above preparation methods, three examples and three comparative examples are given this time, as shown in Table 1.

[0047] Table 1 Mass ratio of component A of room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com