A kind of agwcc electrical contact material with special organizational structure and its preparation method

A technology of electrical contact material and tissue structure, applied in circuits, electrical switches, electrical components, etc., can solve the problems of difficult dispersion of WC reinforced phase particles, low density, and high product bulk resistance, to ensure overall contact resistance stability, Stable temperature rise/low, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

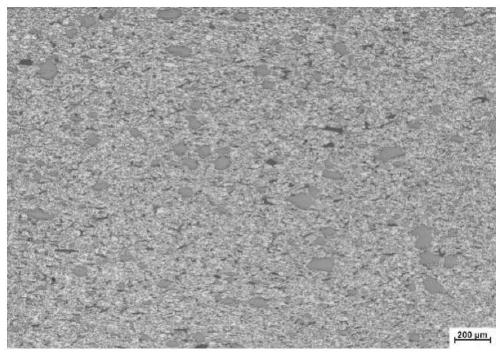

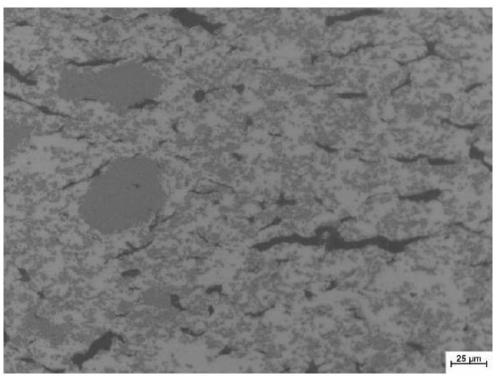

[0089] Taking the preparation of Ag85WC-W-C2 (silver content 85wt%) electrical contact material as an example

[0090] The first step, silver powder (D90=100nm) 0.5wt%; WC powder (D90=10nm)+W powder (D90=5μm) 94.5wt%, Ni powder (D90=50nm) 5% (wt) carries out high-energy ball milling, The ratio of W powder weight / WC powder weight is 1 / 12, the high-energy ball milling speed is 180 rpm, the ball milling time is 6 hours, and the ball-to-material ratio is 10:1.

[0091] In the second step, the composite powder obtained in the first step is mixed with silver powder, the powder mixing speed is 20 rpm, the time is 2 hours, the total silver content is 10%, and the particle size D90 of the silver powder is 100nm.

[0092]The third step is to add silver powder to the sieved powder for wet mixing, and add polyethylene glycol colloid. Acetone can be selected as the wet mixing solution medium, the ratio is total weight of powder (Kg) / volume of solution (L)=2:1, total weight of powder / total...

Embodiment 2

[0105] '" In the first step, silver powder (D90=5 μm) 5wt%; WC powder (D90=2 μm)+W powder (D90=10nm) 94.5wt%, Co powder (D90=100 μm) 0.5wt% carry out high-energy ball milling, wherein The ratio of W powder weight / WC powder weight is 1; the high-energy ball milling speed is 300 rpm, the ball milling time is 2 hours, and the ball-to-material ratio is 2:1.

[0106] In the second step, the composite powder obtained in the first step is mixed with silver powder. The rotation speed is 150 rpm, the time is 10 hours, the total silver content is 15%, and the particle size D90 of the silver powder is 5 μm.

[0107] The third step is to add silver powder to the sieved powder for wet mixing, and add polyethylene glycol colloid. Acetone can be selected as the wet mixing solution medium, the ratio is total powder weight (Kg) / solution volume (L)=1:5, total powder weight / total weight of steel balls=1:10, the speed is 300 rpm, and the time for 2 hours.

[0108] The fourth step is to dry and...

Embodiment 3

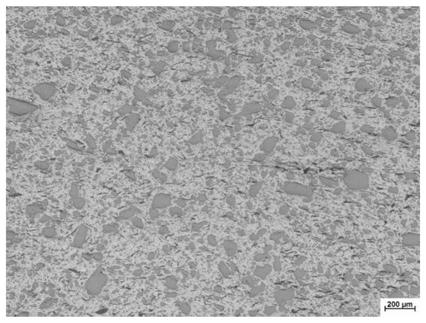

[0120] Taking the preparation of Ag75WCC3.5 (silver content 75wt%) electrical contact material as an example

[0121] In the first step, silver powder (D90=100 μm) 3wt%, WC powder (D90=10 μm) 95wt%, Co powder (D90=10 μm) 2wt% are subjected to high-energy ball milling without W powder; the speed of high-energy ball milling is 150 rpm , the ball milling time is 4 hours, and the ball-to-material ratio is 5:1.

[0122] In the second step, the composite powder obtained in the first step is mixed with silver powder. The powder mixing speed is 100 rpm, the time is 30 hours, the total silver content is 30%, and the particle size D90 of the silver powder is 100nm.

[0123] The third step is to add silver powder to the sieved powder for wet mixing, and add polyethylene glycol colloid. Acetone can be selected as the wet mixing solution medium, the ratio is total weight of powder (Kg) / volume of solution (L)=1:1, total weight of powder / total weight of steel balls=1:10, the rotation speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com