A Method for Improving Hot Workability of Nickel-based Precipitation Strengthened Superalloy with High γ′ Phase Volume Fraction

A volume fraction, precipitation strengthening technology, applied in the field of material processing, can solve the problems of deterioration of thermal processing performance, increase of material flow stress, decrease of plasticity, etc., and achieve the effect of improving thermal processing performance, reducing flow stress and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

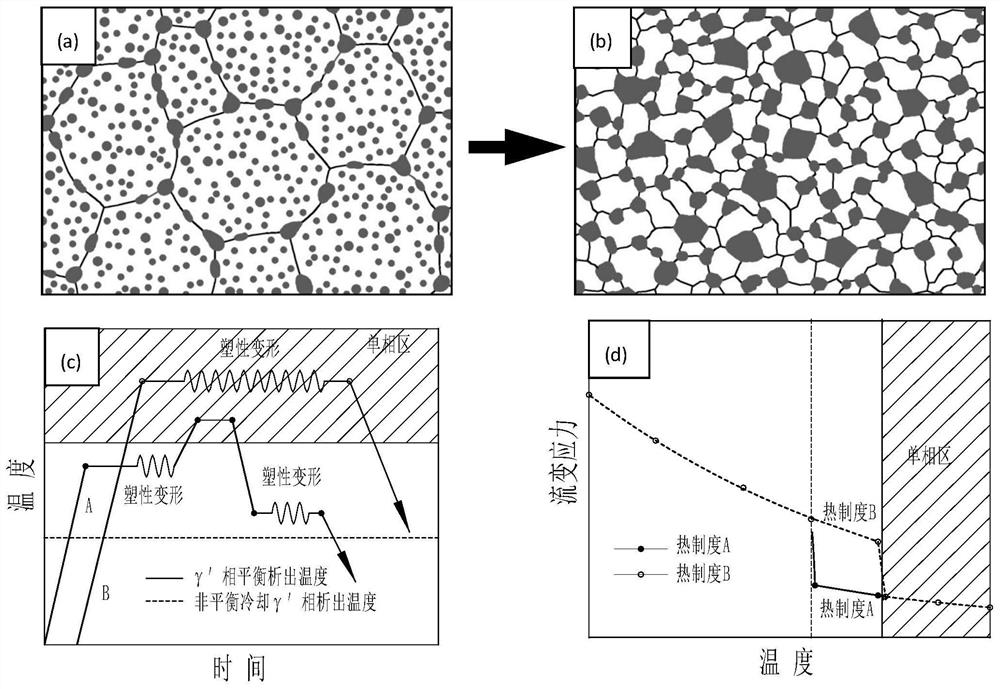

Method used

Image

Examples

Embodiment 1

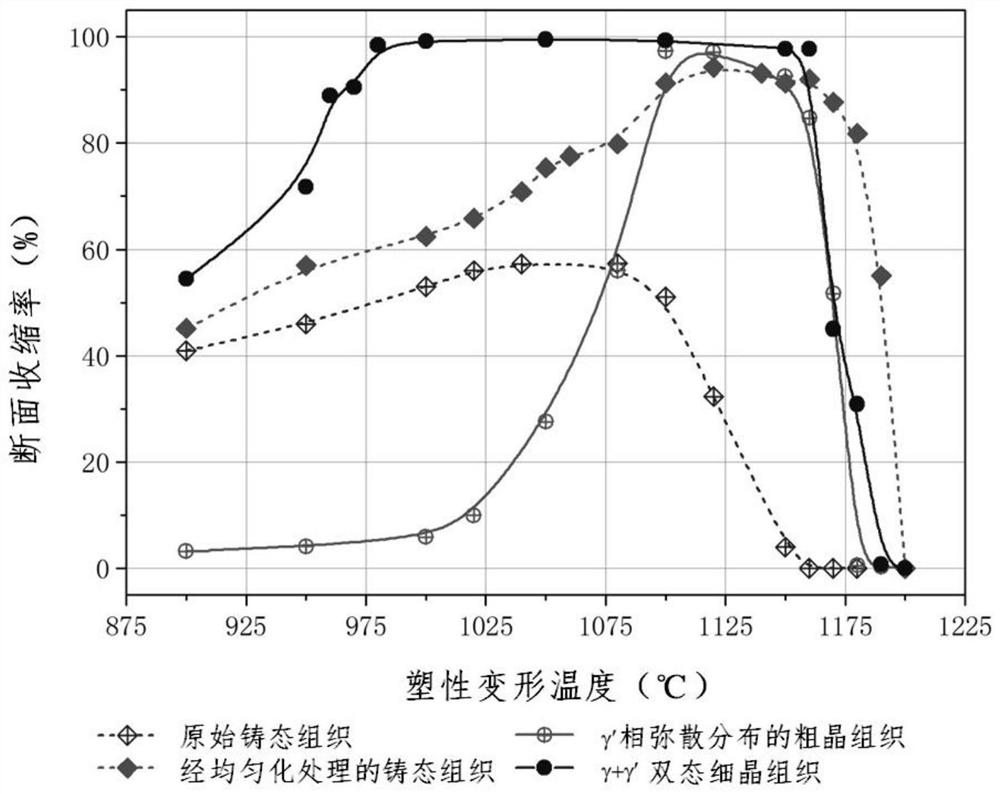

[0073] GH4065 alloy is a high-alloyed nickel-based precipitation-strengthened alloy with a γ′ phase volume fraction exceeding 35%. The high γ′ phase volume fraction makes it difficult to deform GH4065, and the application of traditional thermal deformation process will lead to cracks and scrap. The specific steps for improving the hot working plasticity of this alloy are as follows for application of the present invention:

[0074] (1) Apply vacuum induction + electroslag remelting + vacuum self-consumption triple melting casting process to prepare remelted ingots of Ф508mm, homogenize the surface lathe after heat treatment, and obtain bars with a specification of Ф490×1100mm, and return this specification to the furnace every time for heat preservation The time is 6h;

[0075] (2) After thermodynamic calculation and microstructure observation, it is measured that the volume fraction of the γ′ phase of the GH4065 alloy is 42%, and the complete melting temperature of the γ′ ph...

Embodiment 2

[0084] GH4720Li alloy is a high-alloyed nickel-based precipitation-strengthened alloy with a γ′ phase volume fraction exceeding 35%. The high γ′ phase volume fraction makes GH4720Li difficult to deform, and the application of traditional thermal deformation process will lead to cracks and scrap. The specific steps for improving the hot working plasticity of this alloy are as follows for application of the present invention:

[0085] (1) Vacuum induction + electroslag remelting + vacuum self-consumption triple casting process is used to prepare consumable ingots of Ф508 mm, and the surface is polished after homogenization of heat treatment to obtain rods with a specification of Ф490 × 1100 mm. This specification is returned to the furnace for heat preservation every time The time is 6h;

[0086] (2) After thermodynamic calculation and microstructure observation, it is measured that the volume fraction of the γ′ phase of the GH4720Li alloy is 46%, and the complete melting tempe...

Embodiment 3

[0094] GH4175 alloy is a high-alloyed nickel-based precipitation-strengthened alloy with a γ′ phase volume fraction exceeding 35%. The high γ′ phase volume fraction makes it difficult to deform GH4175, and the application of traditional thermal deformation process will lead to cracks and scrap. The specific steps for improving the hot working plasticity of this alloy are as follows for application of the present invention:

[0095](1) Prepare a Ф410mm remelted ingot by applying the vacuum induction + vacuum self-consumption double casting process, homogenize the surface finish after heat treatment, and obtain a Ф390×1000mm bar.

[0096] (2) After thermodynamic calculation and microstructure observation, it is measured that the volume fraction of the γ′ phase of the GH4175 alloy is 60%, and the complete melting temperature of the γ′ phase is about 1185°C;

[0097] (3) Heat up the Ф390×1000mm bar to T s -40°C is 1145°C, heat preservation for 6 hours for the first heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com