Construction method for large-span continuous beam UHPC columns

A construction method and column section technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of continuous growth of deformation, and achieve the effect of solving the continuous growth of deformation, reducing the interference of secondary vertical formwork, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The construction method of the long-span continuous beam UHPC column according to the present invention is described below with specific examples.

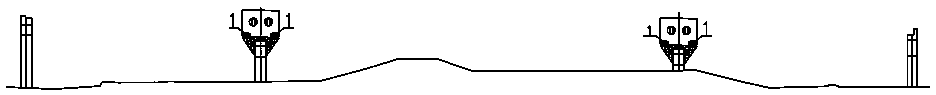

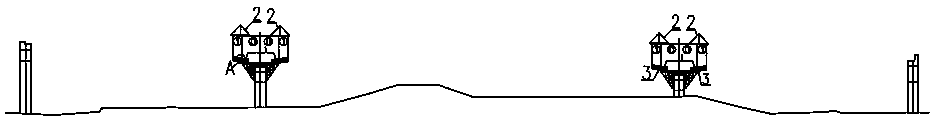

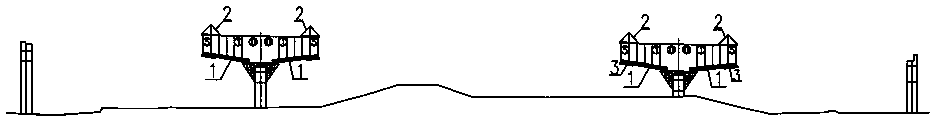

[0018] Such as Figure 1-7 Shown, above-mentioned construction method comprises the steps:

[0019] In the first step, the UHPC column segment 1 is prefabricated, such as Figure 8 , 9 As shown, each UHPC column segment 1 is provided with longitudinal reinforcement 1.1, and the two ends of the UHPC column segment 1 are provided with a cast-in-place joint surface structure 1.2 with a concave middle, and one end of the UHPC column segment 1 is covered with There are U-shaped positioning steel plates 1.3 for connecting adjacent UHPC column segments, and shear nails 1.4 are welded on the inner and outer sides of the bottom plate, left side plate, and right side plate of the U-shaped positioning steel plate 1.3;

[0020] The second step is to set up brackets next to the main pier and preload the brackets, then install the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com