Powder liquid mixing and emulsifying machine and working method thereof

An emulsifying machine and powder-liquid technology, applied in the direction of mixing methods, mixers, chemical instruments and methods, etc., can solve the problems of uneven mixing of emulsifying machines, small application range of equipment, and poor emulsification effect, etc., to achieve convenient cleaning of equipment, High practicability and the effect of improving the effective contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

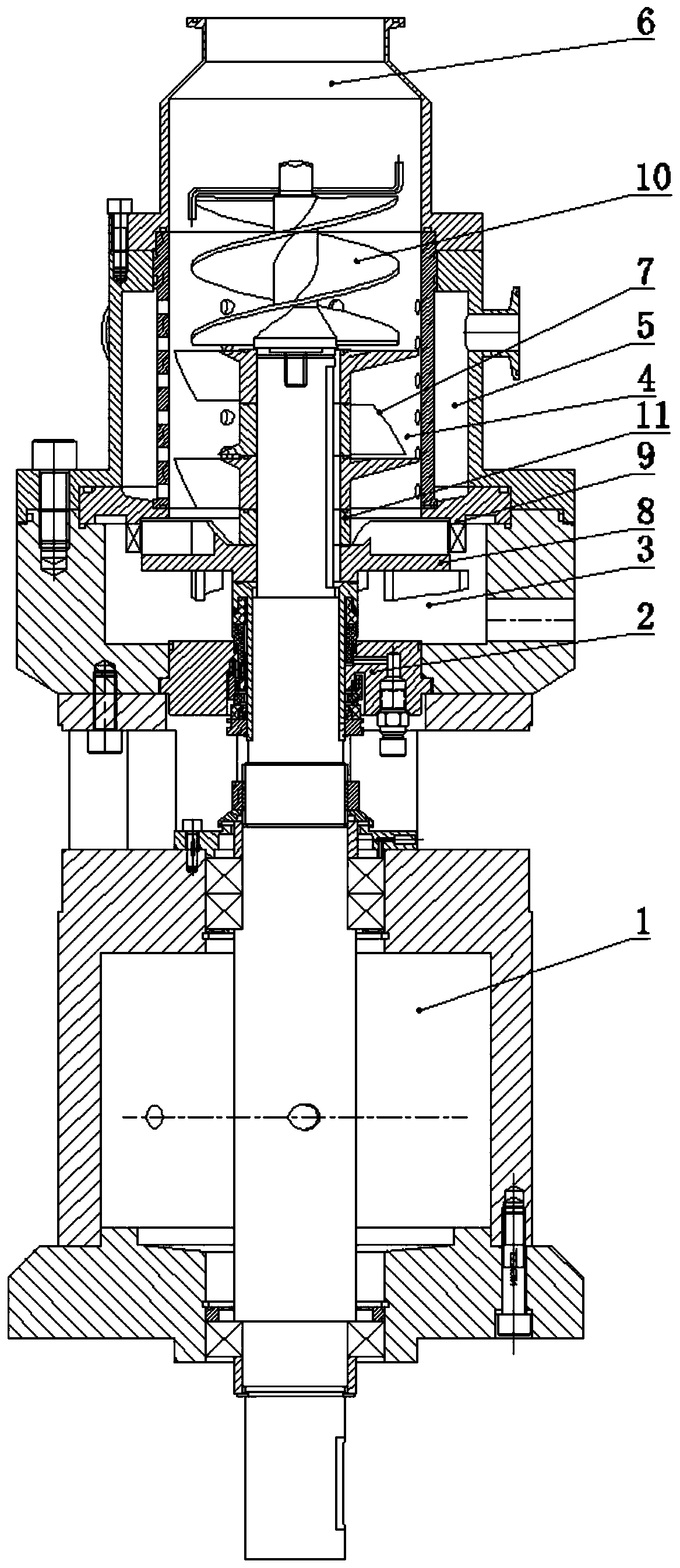

[0047] Such as Figure 1-8 A powder-liquid mixing and emulsifying machine is shown, comprising: a base body 1, a machine seal 2, a discharge cavity 3, a branch cylinder 4, a side material feeding cavity 5 and a top feeding cavity 6, wherein the base body 1 is provided with a main shaft , The outer side of the main shaft is provided with an organic seal 2, a shunt cylinder 4, and a top feed cavity 6 in sequence, the mechanical seal 2 is provided on the top of the base 1, and the outer side of the mechanical seal 2 is provided with a discharge cavity 3, the discharge cavity 3 is connected to the split tube 4, a side material feeding cavity 5 is provided outside the split tube 4, the side material feeding cavity 5 is in communication with the split tube 4, and the top of the split tube 4 is in communication with the top feeding cavity 6.

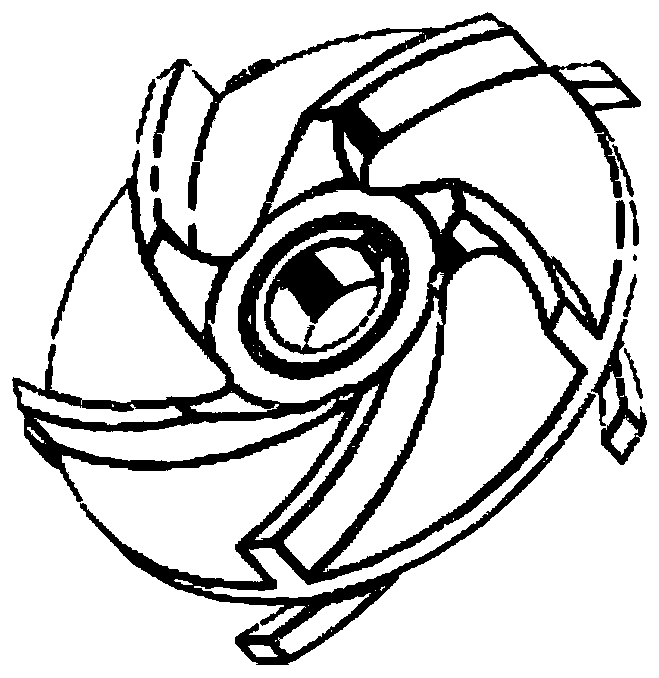

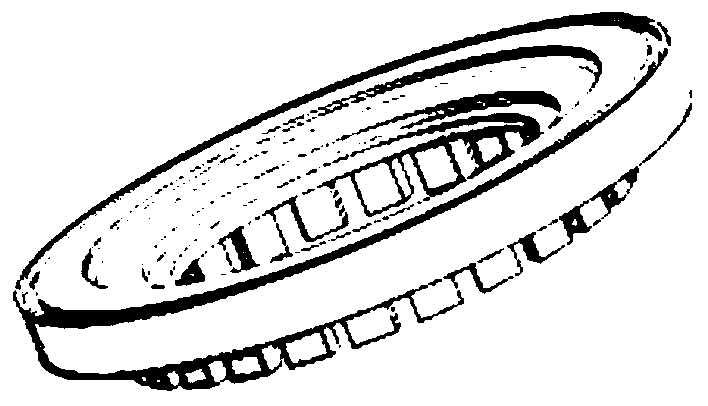

[0048] The shunt cylinder 4 described in this embodiment is provided with an impeller 7, a rotor 8 and a stator 9, and a rotor 8 is provided in th...

Embodiment 3

[0062] Such as figure 1 with 8 A powder-liquid mixing and emulsifying machine is shown, comprising: a base body 1, a machine seal 2, a discharge cavity 3, a branch cylinder 4, a side material feeding cavity 5 and a top feeding cavity 6, wherein the base body 1 is provided with a main shaft , The outer side of the main shaft is provided with an organic seal 2, a shunt cylinder 4, and a top feed cavity 6 in sequence, the mechanical seal 2 is provided on the top of the base 1, and the outer side of the mechanical seal 2 is provided with a discharge cavity 3, the discharge cavity 3 is connected to the split tube 4, a side material feeding cavity 5 is provided outside the split tube 4, the side material feeding cavity 5 is in communication with the split tube 4, and the top of the split tube 4 is in communication with the top feeding cavity 6.

[0063] The mechanical seal 2 described in this embodiment includes an inner mechanical seal body 21, a first moving ring 22, a first static ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com