Leakage restoring device

A gas, gas-liquid separation technology, applied in the direction of fuel air filter, fuel air intake, engine components, etc., can solve the problems of increasing the number of parts and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

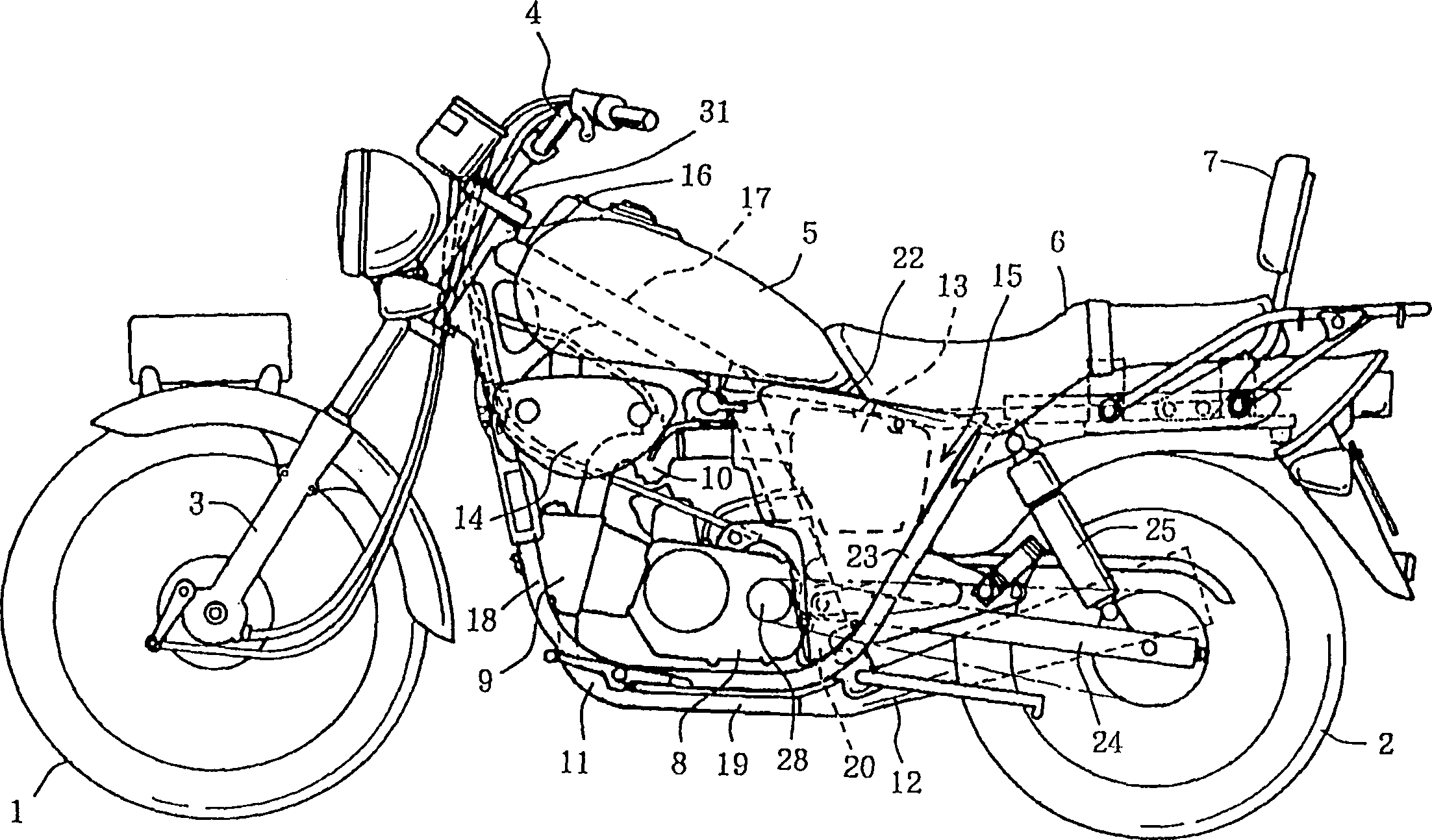

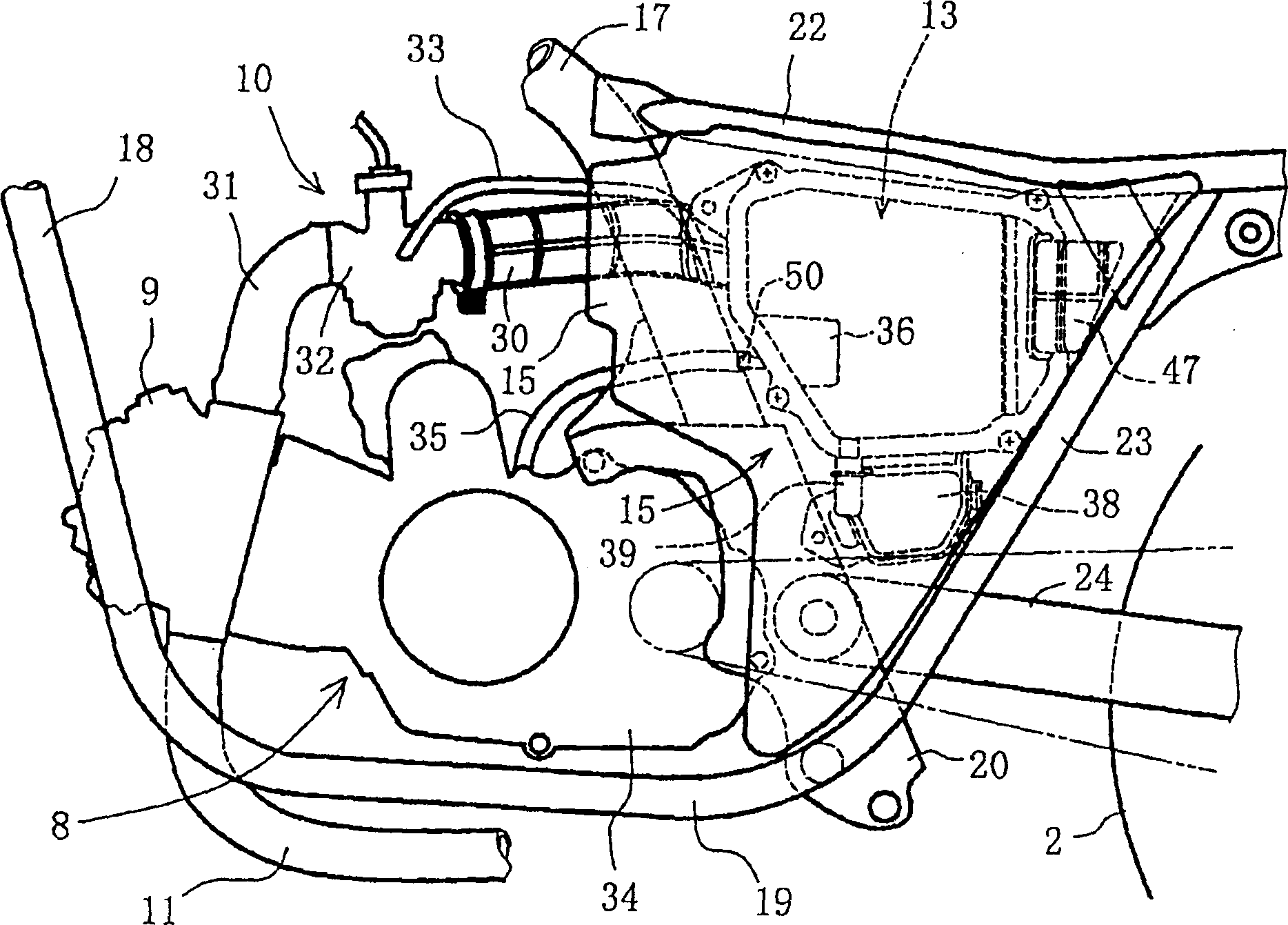

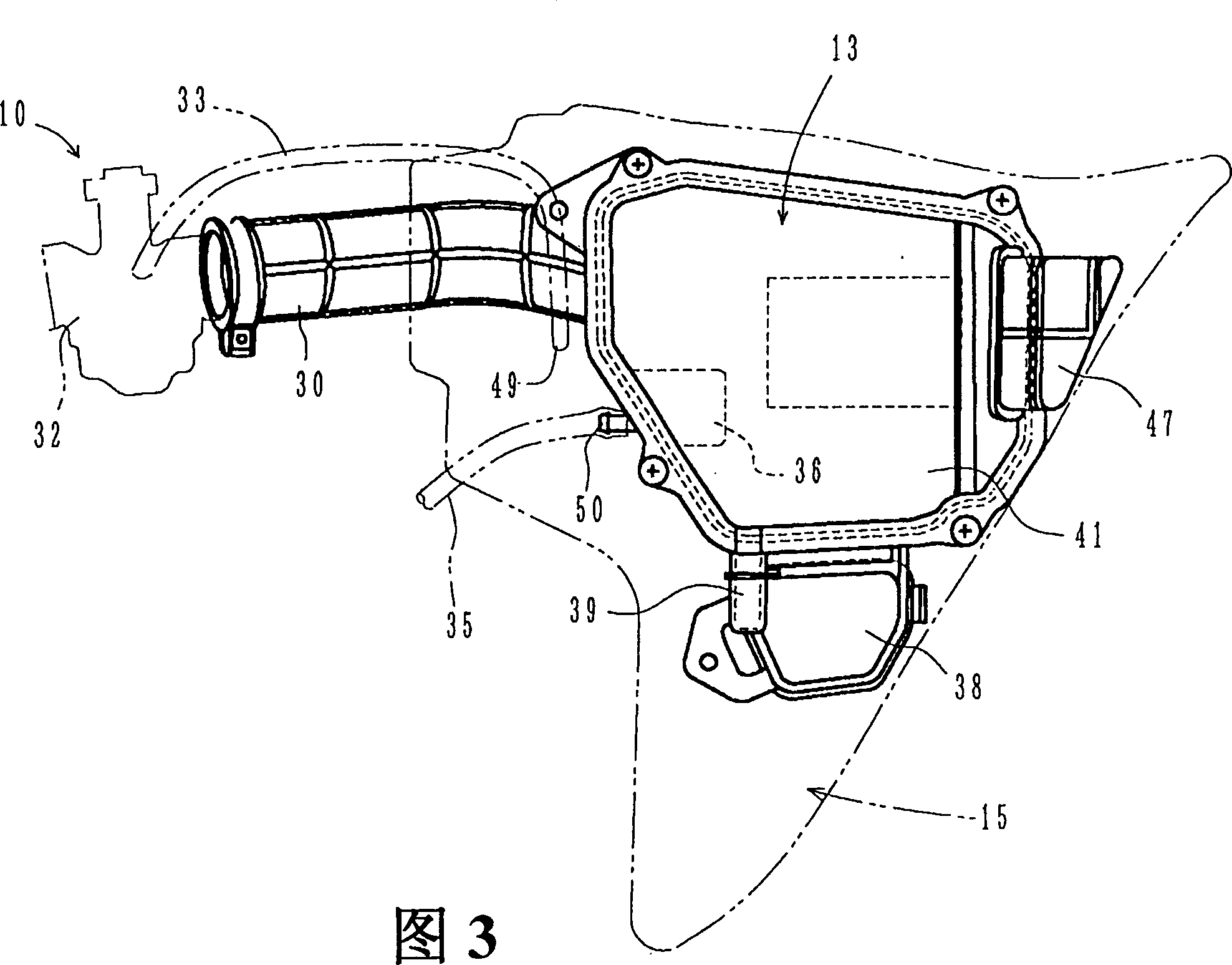

[0014] An embodiment of the present invention applicable to a two-wheeled motor vehicle will be described with reference to the drawings. figure 1 It is a left side view showing the direction of travel of the appearance of the two-wheeled motor vehicle; figure 2 It is an enlarged view showing the main parts around the engine; Fig. 3 is a further enlarged side view showing the housing part of the air filter; Fig. 4 is a cross-sectional view thereof; Figure 5 It is a side view of the housing body part showing its interior with the cover removed; Image 6 It is a partially enlarged view showing a part of the reduction chamber cut away.

[0015] First, the overall structure of this two-wheeled motor vehicle will be schematically described. Such as figure 1 As shown, the two-wheeled motor vehicle is an American structure, and it has the following characteristics: a front wheel 1 and a rear wheel 2 forming a long track, a front fork 3 with a large caster angle of the steering w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com