A method for on-site complete crushing of road cement pavement and a pavement crusher

A technology of cement pavement and crushing method, applied in the direction of roads, roads, road repair, etc., can solve the problems of extremely high pre-crushing requirements and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the on-site full crushing method of road cement pavement and the pavement crusher of the present invention in conjunction with the accompanying drawings.

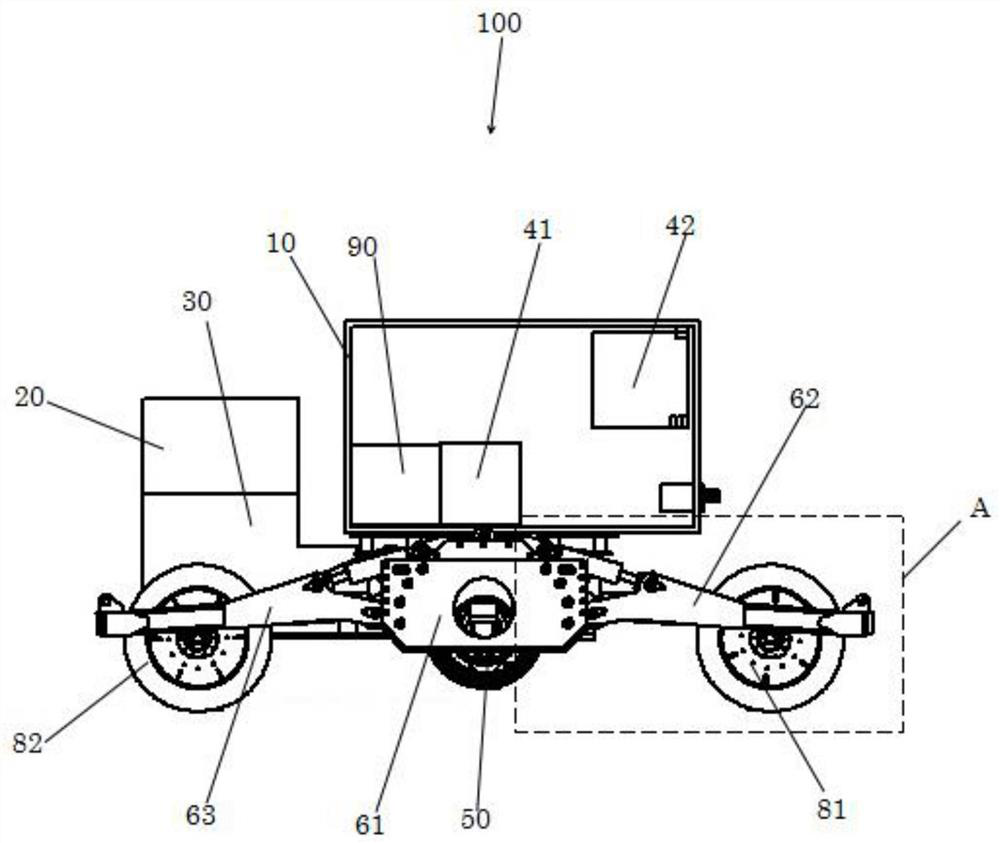

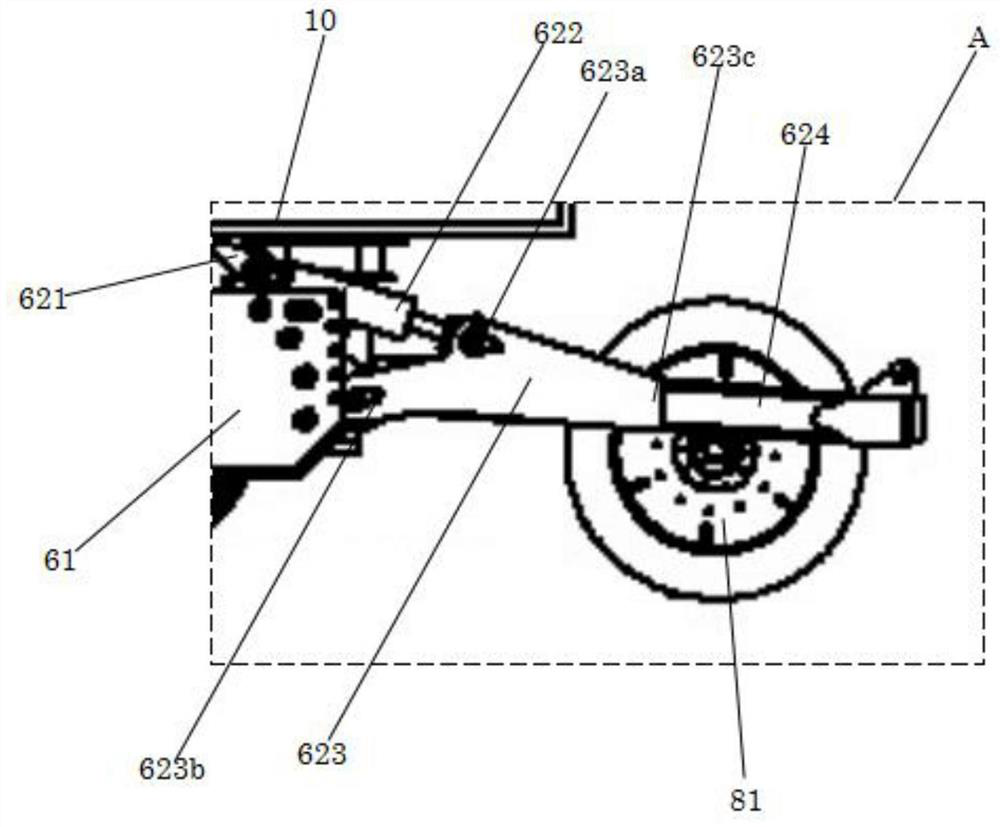

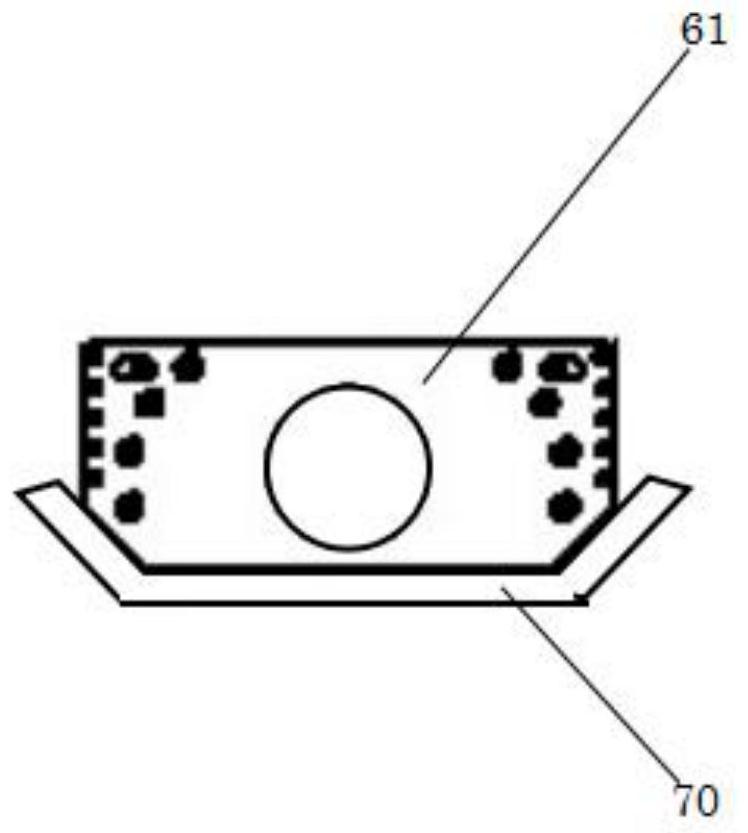

[0023] Such as figure 1 As shown, the pavement breaker 100 includes: a frame 10, an oil tank 20, a water tank 30, a driving mechanism, a crushing mechanism, a lifting mechanism, and a stabilizing plate 70 ( image 3 shown).

[0024] The frame 10 is a square frame structure, and the outer periphery of the square frame structure is provided with a shell structure. The oil tank 20 and the water tank 30 are all fixedly arranged with the frame 10 .

[0025] The driving mechanism is installed on the frame 10 and includes an engine 41 connected to the oil tank 20 and a hydraulic system 42 driven by the engine 41 .

[0026] The crushing mechanism is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com