Harmless resourceful treatment system for vinasse waste and method for producing humic acid

A treatment system and recycling technology, applied in the field of humic acid production and the harmless recycling of distiller's grain waste, can solve the problems of difficulty in processing waste gas and waste liquid, low utilization efficiency, and ineffective utilization of distiller's grain waste water, etc. Solve the problem of environmental pollution and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

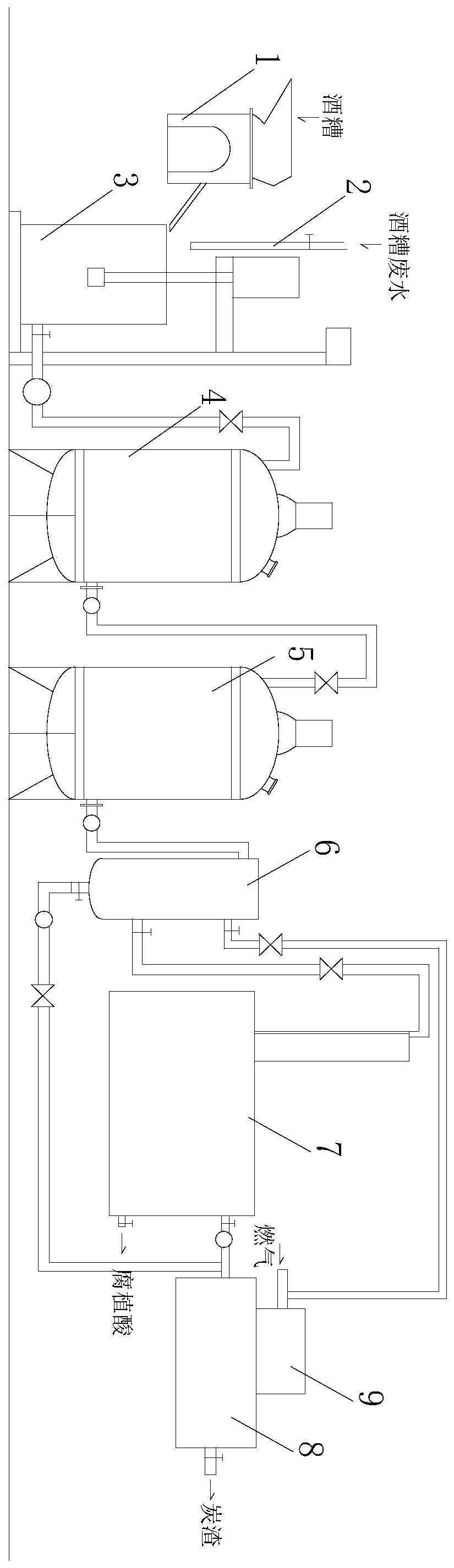

[0023] Example 1: see figure 1 , a kind of distiller's grain waste harmless resource treatment system, comprising distiller's grain waste conveyor belt, distiller's grain waste liquid conveying pipe 2 and processing equipment, said processing equipment is composed of pulverizer 1, homogenizer 3, anaerobic fermentation tank 4, aerobic Fermentation tank 5, multi-phase separator 6, extraction and separation equipment 7 and carbonization equipment 8. The distiller's grains waste conveyor belt is pulverized by the pulverizer 1 and then transported to the homogenizer 3, where an emulsifier is added for homogenization, and the distiller's grains are pulverized Afterwards, it is convenient for the extraction of humic acid and subsequent homogenization and separation. The distiller’s grain waste liquid delivery pipe 2 transports the distiller’s grain waste liquid into the homogenizer, and the homogenizer 3 transports the mixed and emulsified material to the Fermentation and sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com