Plate punching device for furniture production

A punching device and plate technology, applied in positioning devices, manufacturing tools, boring/drilling, etc., can solve the problems of reduced work efficiency, slow clamping speed, cumbersome operation, etc., to reduce clamping time, clamping Stabilize and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

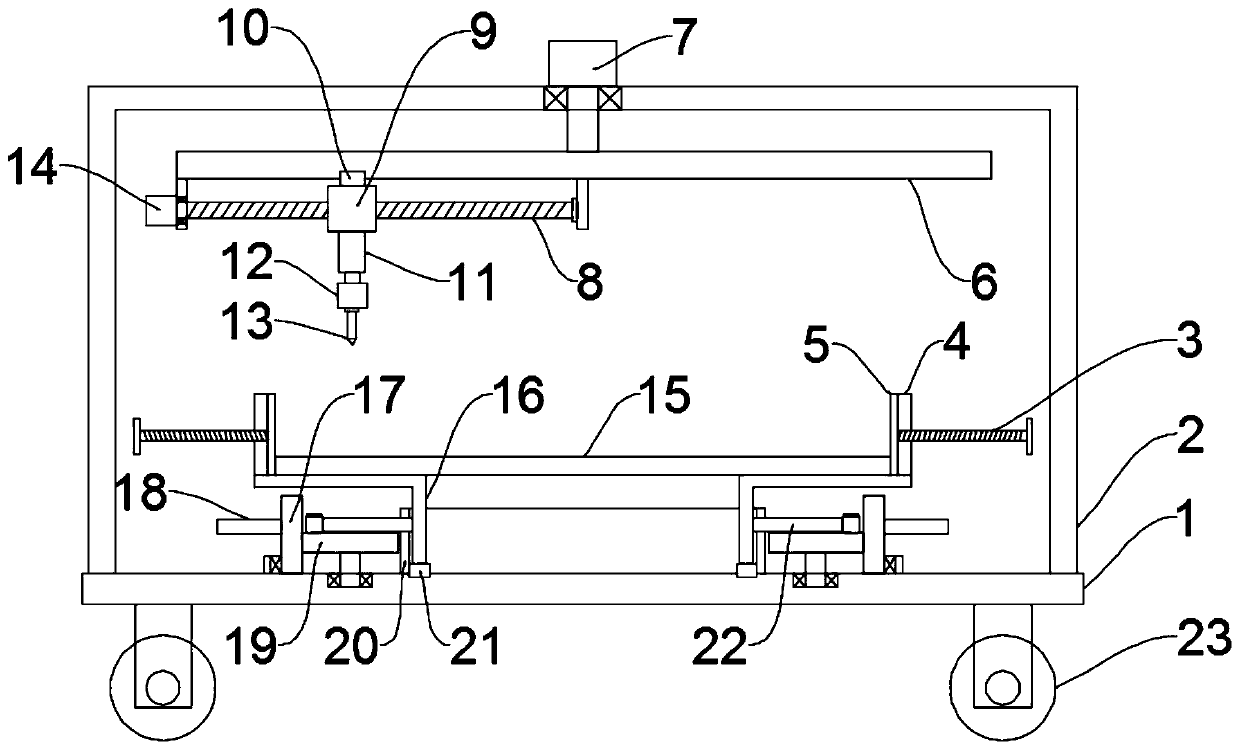

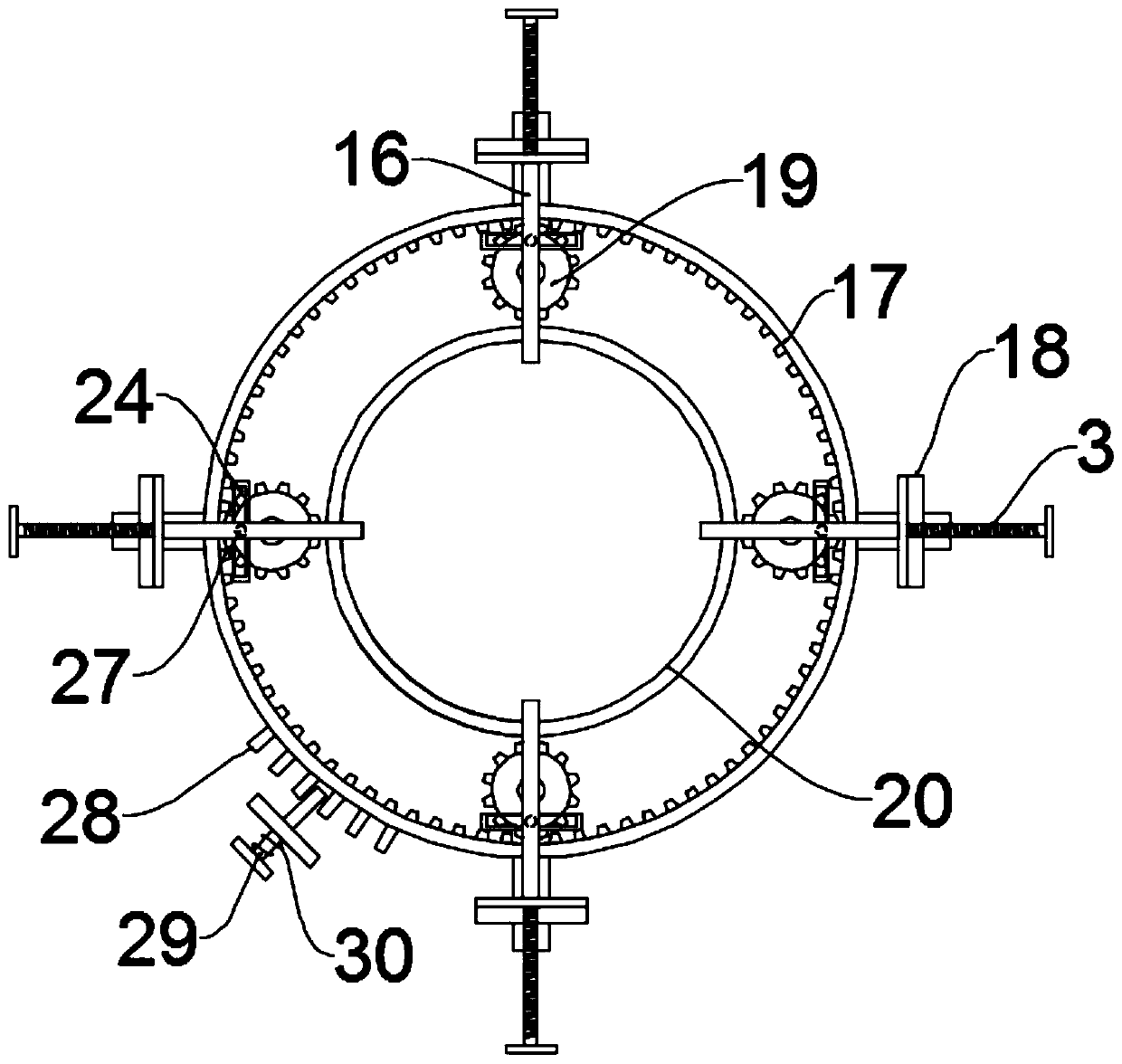

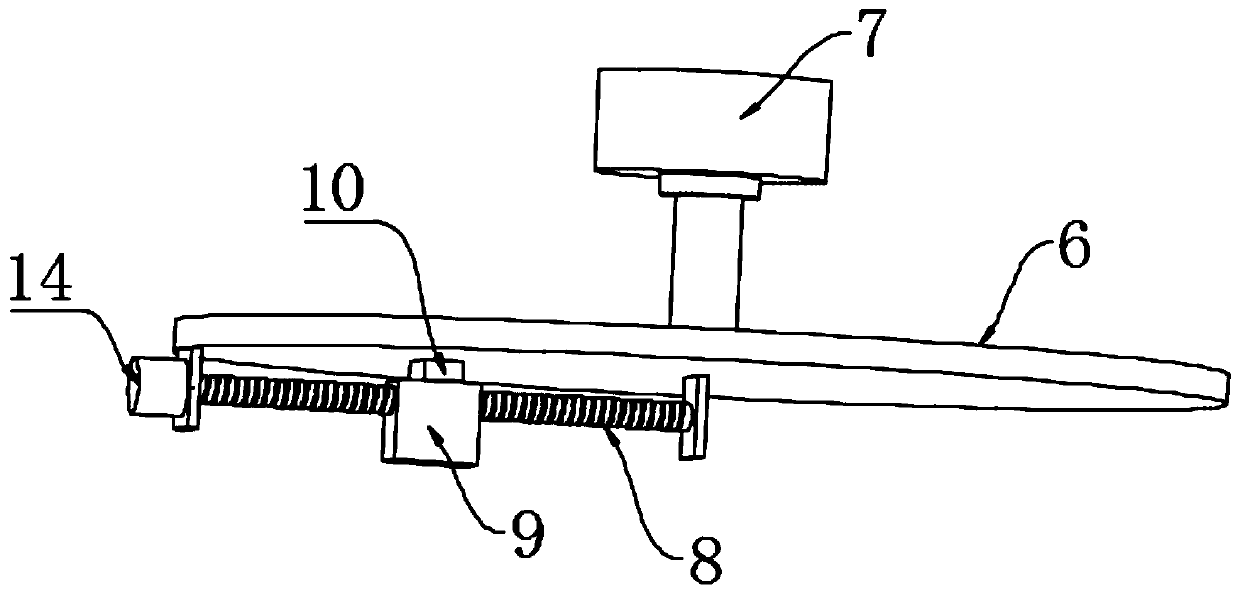

[0027] see Figure 1~3 , in an embodiment of the present invention, a board punching device for furniture production, including a workbench 1, a clamping mechanism and a punching mechanism, the upper surface of the workbench 1 is equipped with a clamping mechanism for fast clamping board 4 materials, A punching mechanism is arranged above the clamping mechanism. Supporting legs are installed on the four corners of the bottom of the workbench 1, and rollers 23 are installed at the bottom of the supporting legs. The rollers 23 are self-locking rollers to facilitate the movement of the device. The clamping mechanism includes a plurality of splints 4 arranged circumferentially around the sheet body 15 and a driving assembly for driving the plurality of splints 4 to move synchronously to the sheet body 15 and clamp them. Anti-slip protrusions are provided on each of the plurality of splints 4 In this embodiment, the number of splints 4 is preferably four and distributed in four dir...

Embodiment 2

[0031] see Figure 4 The difference between the embodiment of the present invention and the embodiment is that, in order to avoid the dust generated during drilling from affecting the health of the workers, a suction nozzle 25 is installed on the mounting block 9 through a mounting rod, and the suction nozzle 25 is located at the drill bit 13 On the side, the suction nozzle 25 is connected with a trachea, and the other end of the trachea is connected with the vacuum cleaner 26, through which the dust generated is sucked in, so as to avoid flying around and affecting the health of the staff.

[0032] The working principle of the present invention is: when the present invention is in use, the inner ring gear 17 is rotated by the handle 18, and the inner ring gear 17 drives a plurality of gears 19 to rotate synchronously, and the gears 19 drive T through the cylindrical pin 27 and the through groove 24. The shape rod 22 moves, and the T-type rod 22 drives the multiple splints 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com