Drill fixing device used during machining holes in strip-shaped plate at equal intervals

The technology of a fixing device and a drilling device is applied in the field of clamping tools, which can solve the problems of poor economy, cumbersome processing process, low efficiency, etc., and achieve the effects of strong linkage, improved construction efficiency, and simplified technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be explained and described in detail below in conjunction with the accompanying drawings.

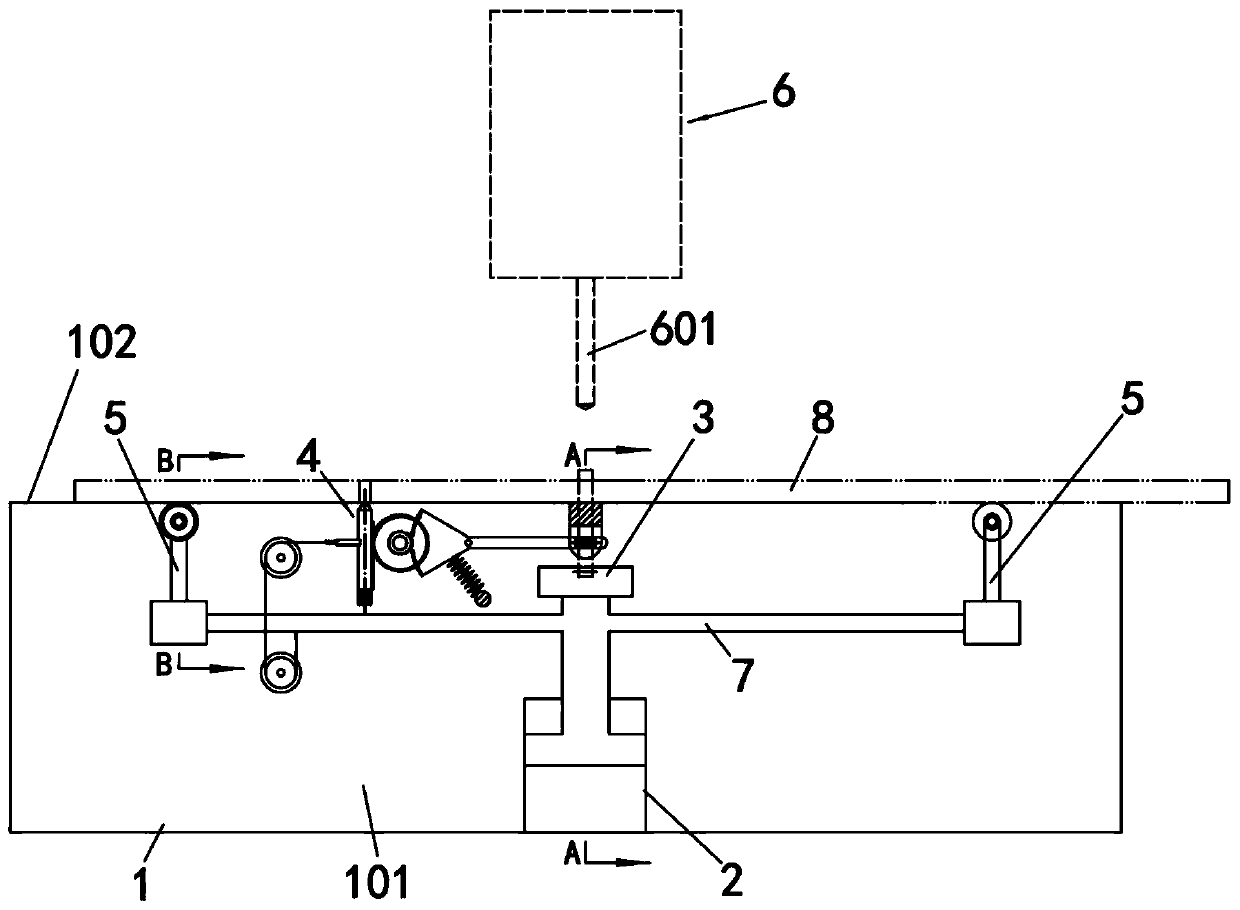

[0037] refer to Figure 1 to Figure 14 As shown, a drilling fixture for machining equidistant holes on a strip is mounted on the underside of the drilling device 6 . The drilling device 6 includes a vertically arranged drill bit 601 with a downward tip, and the drilling device 6 can drive the drill bit 601 to rotate. The drilling device 6 can be, for example, a Z3040 drilling machine. The drilling fixing device in the present invention can be installed on the platform of the Z3040 drilling machine or other common drilling machines. The drilling fixing device of the present invention can use the processed through hole to determine the clamping position when processing the subsequent through hole to be processed, which simplifies the process and improves the construction efficiency.

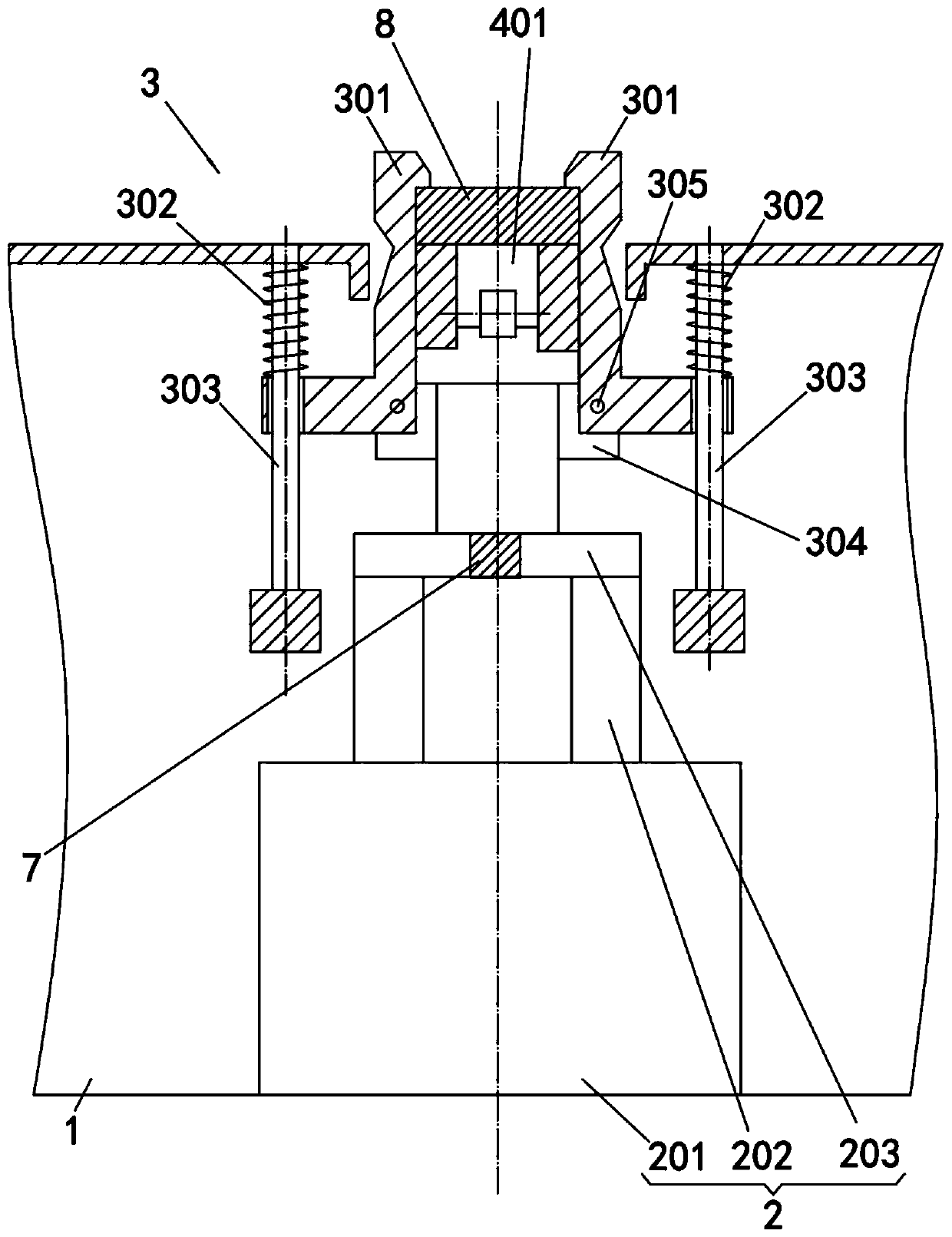

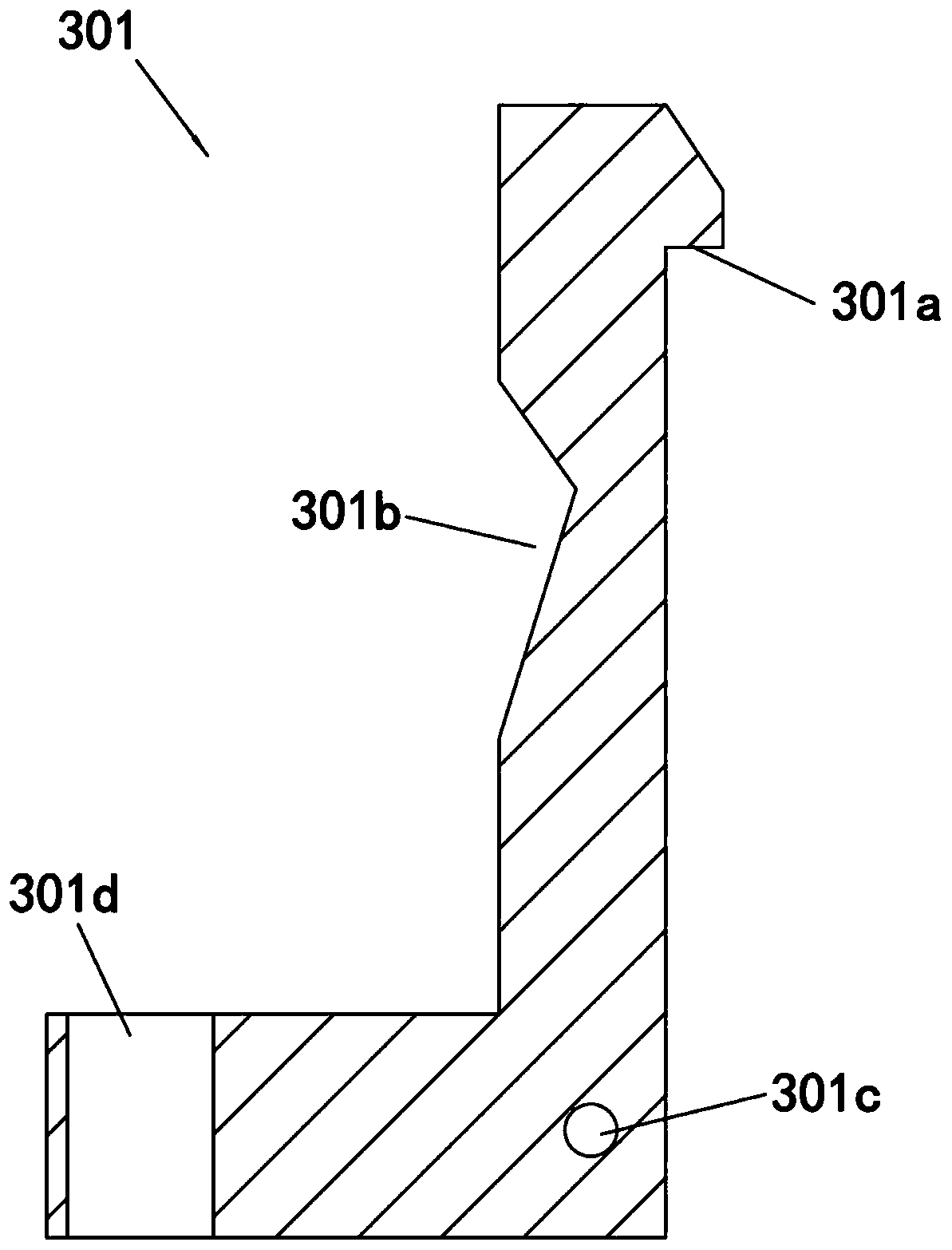

[0038] Wherein, the drilling fixing device includes a housing 1 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com