Device for manufacturing double-axis oriented PVC pipe elbow and method for manufacturing elbow

A technology of biaxial orientation and PVC pipes, which is applied to household components, household appliances, and other household appliances, and can solve problems such as difficult quality control, complicated processing technology, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

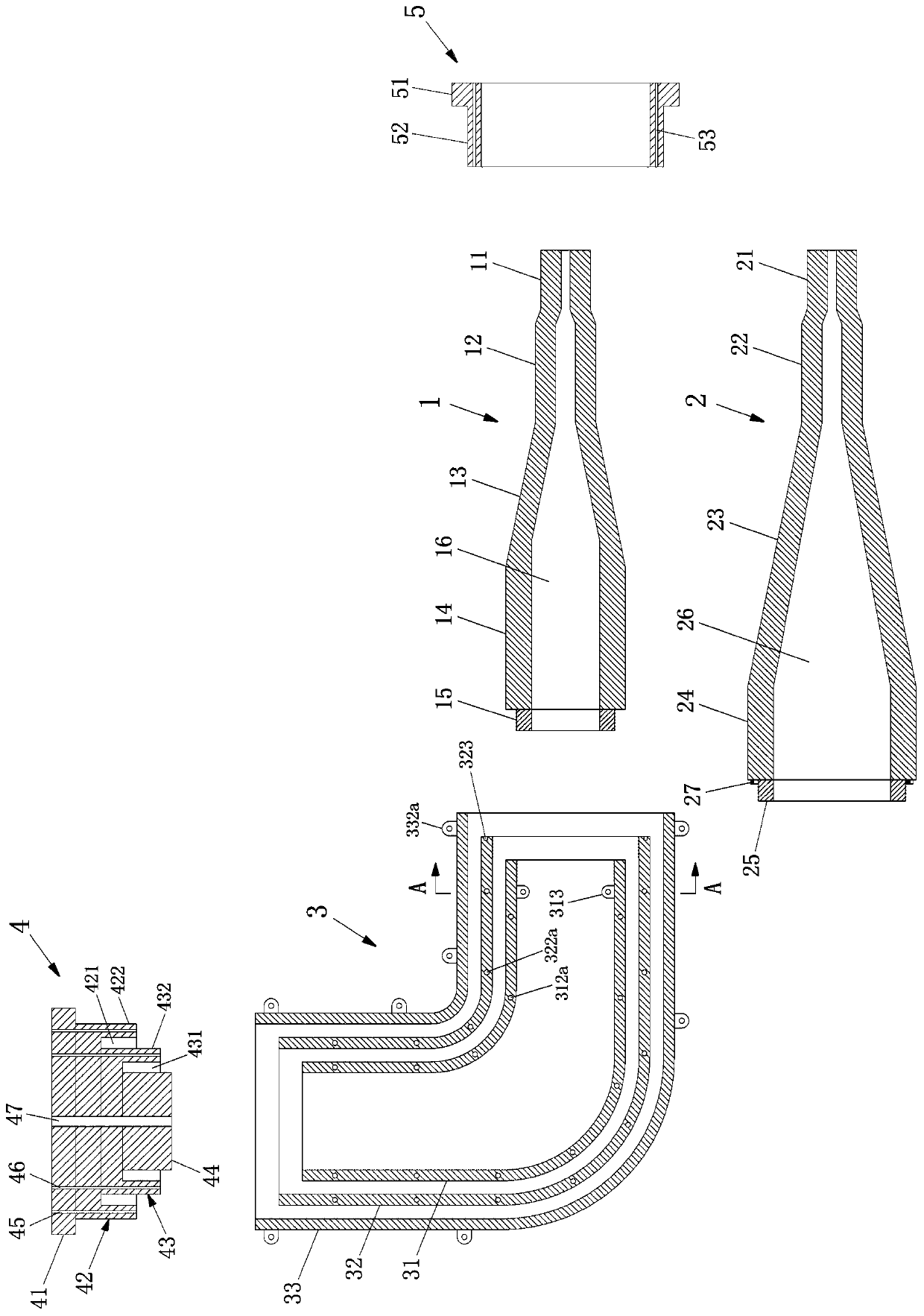

[0057] like figure 1 As shown, the present embodiment provides a device for making biaxially oriented PVC pipe elbows, which includes a first base tube expansion die 1, a second base tube expansion die 2, an elbow forming die 3, and a plug at the end of the die 4 and a kit consisting of a mold head plug cover 5.

[0058] The first blank tube expansion die 1 is used to be connected to one end of the elbow forming die 3 (see Image 6 ), which includes the first guide section 11, the first sealing section 12, the first expansion section 13 and the first sizing section 14 connected in sequence; the first guide section 11 is a cylinder for introducing the Expanded blank tube; the first sealing section 12 is also a cylinder and its outer diameter is slightly larger than the outer diameter of the first guiding section 11, and the first sealing section 12 and the first guiding section 11 are connected through a smooth transition through a tapered surface; The first expansion section...

Embodiment 2

[0078] The method of the present embodiment comprises the steps:

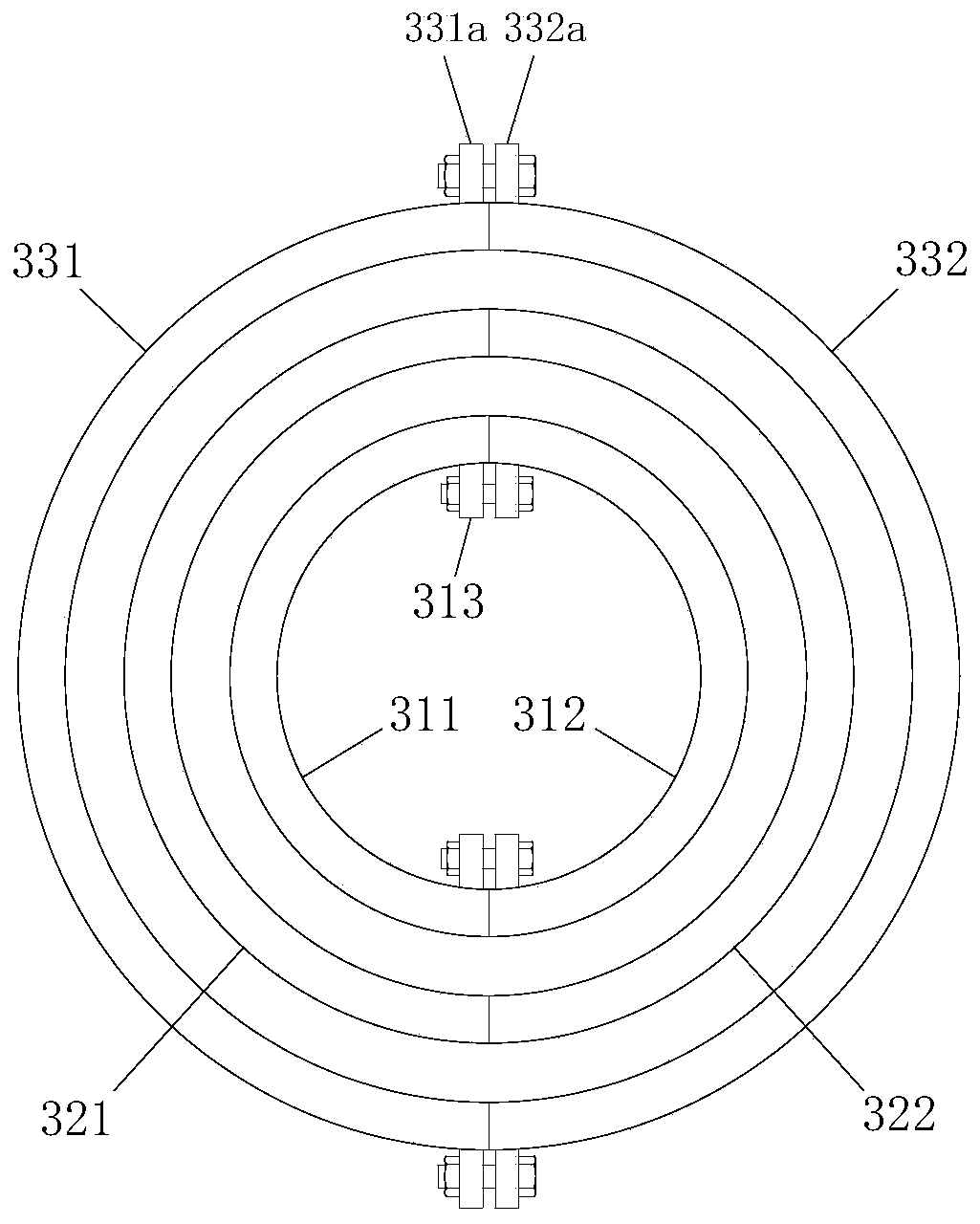

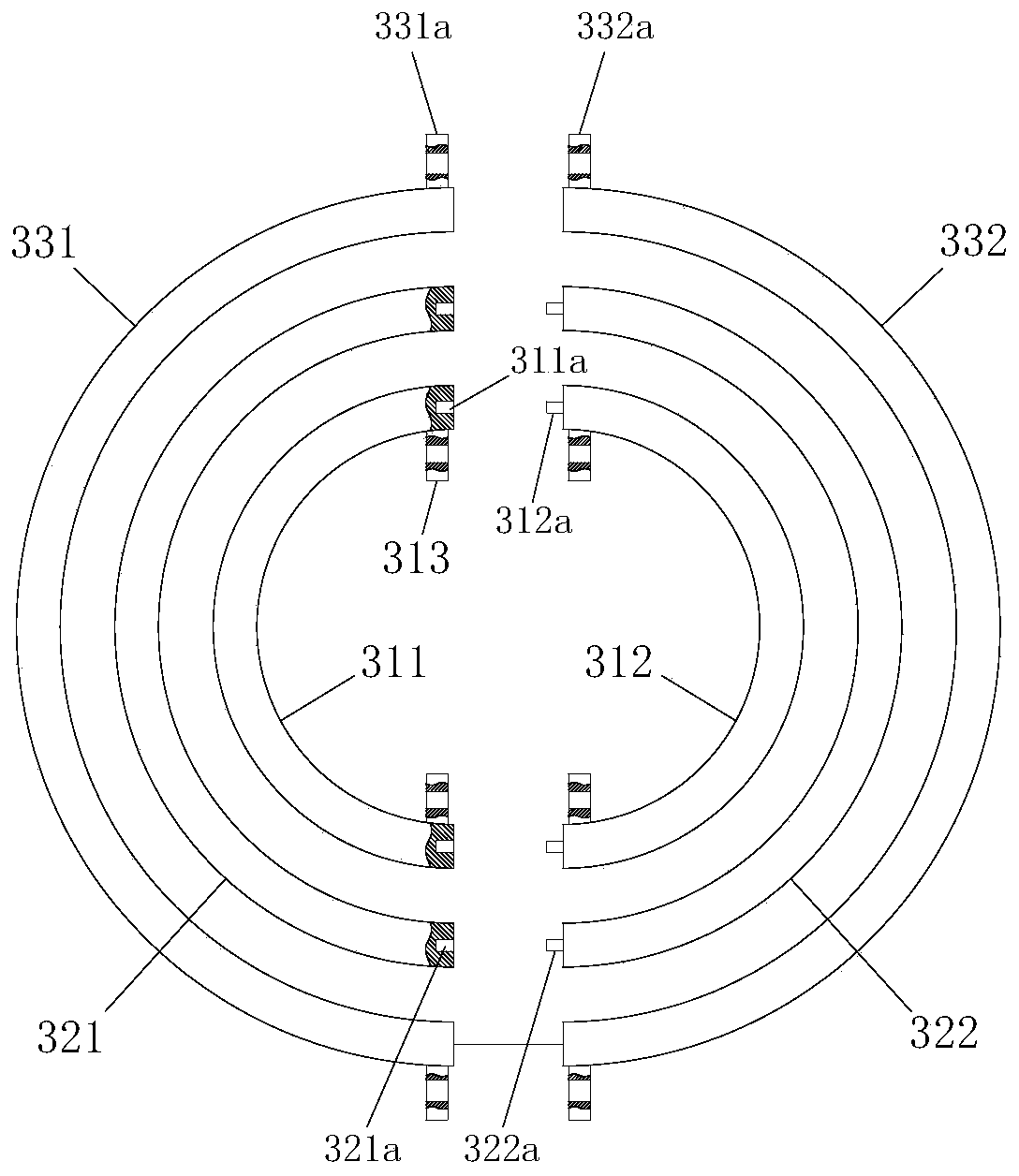

[0079] S1. Assembling the elbow forming mold 3: the middle layer mold body 32 is placed outside the inner layer mold body 31, and the outer layer mold body 33 is placed outside the inner layer mold body 32;

[0080] Wherein, when the first half-mold 311 is docked with the second half-mold 312, the positioning is realized by the cooperation of the first positioning groove 311a and the first positioning post 312a, and there is no need to lock the first half-mold 311 and the second half-mold 312 after positioning. When the third half-mold 321 and the fourth half-mold 322 are docked, the positioning is realized by the cooperation of the second positioning groove 321a and the second positioning post 322a, and the third half-mold 321 and the fourth half-mold 322 do not need to be locked after positioning; When the fifth half-mold 331 and the sixth half-mold 332 are docked, the locking of the two is realized through t...

Embodiment 3

[0092] The method of the present embodiment comprises the steps:

[0093] S1. Assembling the elbow forming mold 3: the middle layer mold body 32 is placed outside the inner layer mold body 31, and the outer layer mold body 33 is placed outside the inner layer mold body 32;

[0094] Wherein, when the first half-mold 311 is docked with the second half-mold 312, the positioning is realized by the cooperation of the first positioning groove 311a and the first positioning post 312a, and there is no need to lock the first half-mold 311 and the second half-mold 312 after positioning. When the third half-mold 321 and the fourth half-mold 322 are docked, the positioning is realized by the cooperation of the second positioning groove 321a and the second positioning post 322a, and the third half-mold 321 and the fourth half-mold 322 do not need to be locked after positioning; When the fifth half-mold 331 and the sixth half-mold 332 are docked, the locking of the two is realized through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com