Automobile front auxiliary frame assembly

A front subframe and assembly technology, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve problems such as reducing the rigid connection between the car body and the front subframe, and aggravating the vibration of the front subframe. The effect of dispersing stress and enhancing the connection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

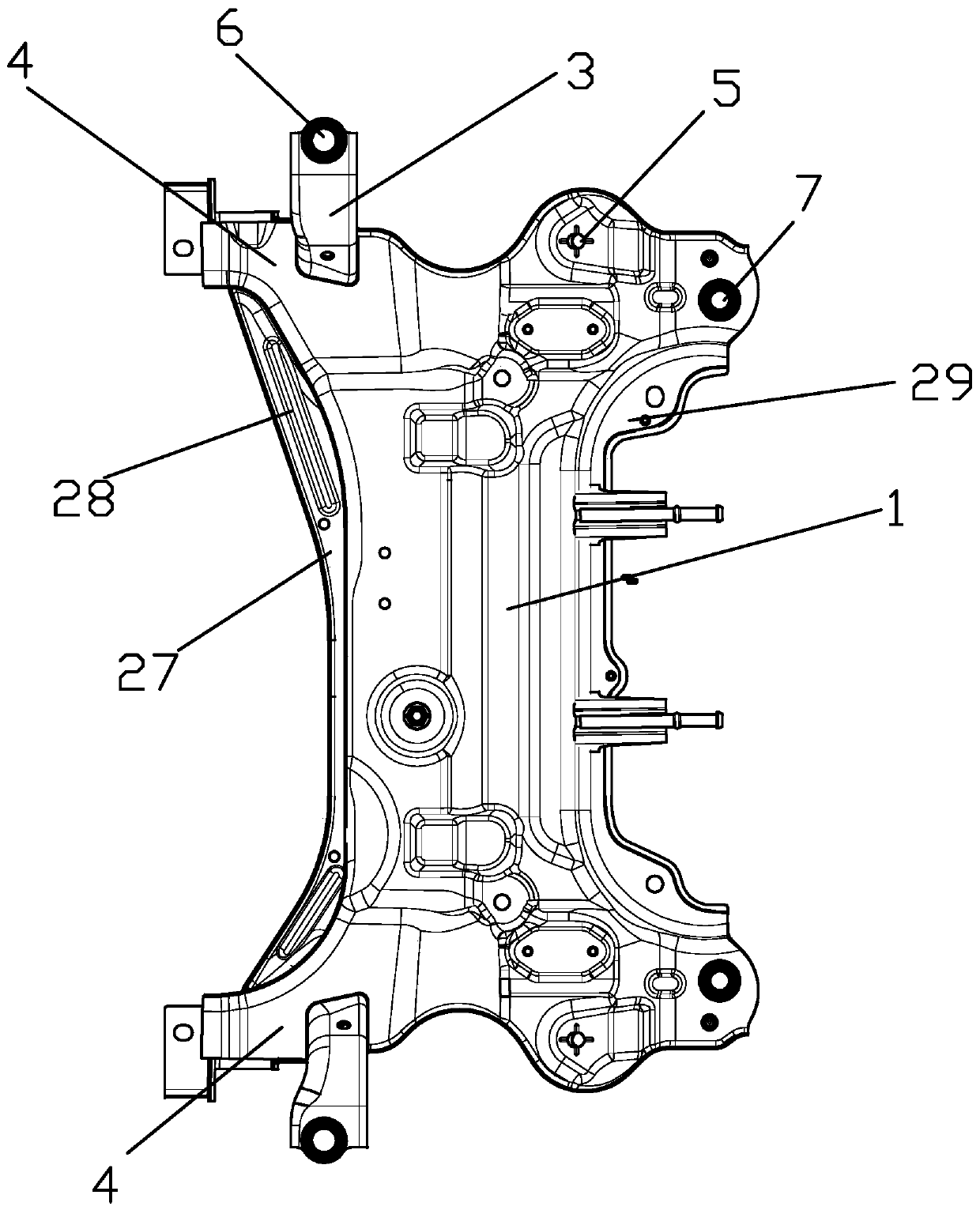

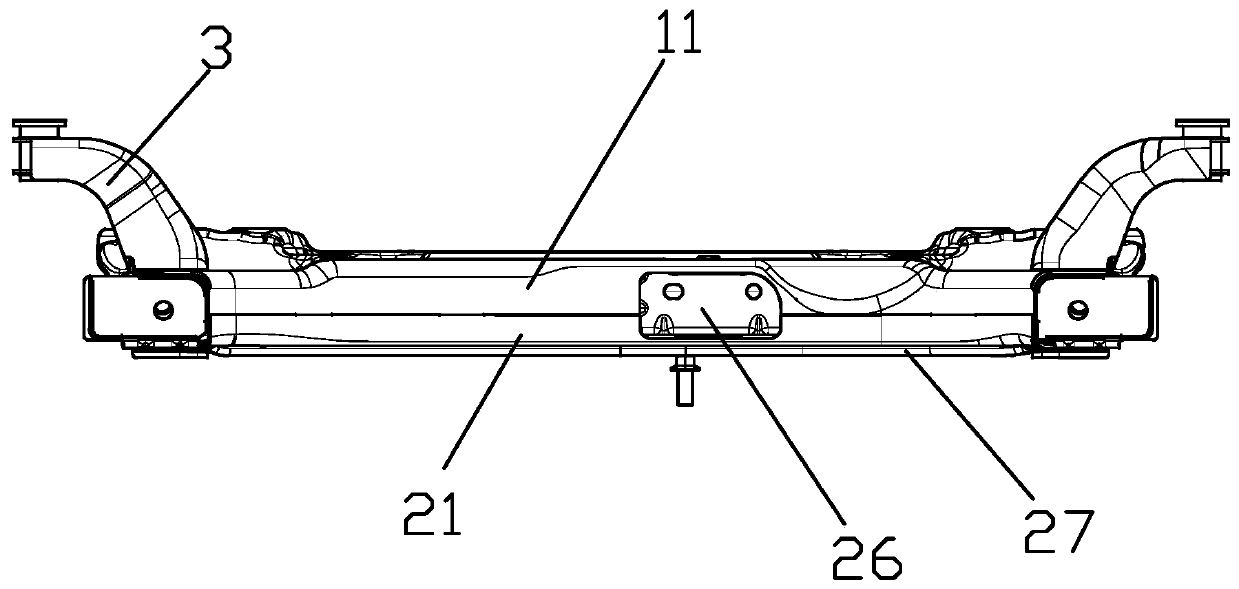

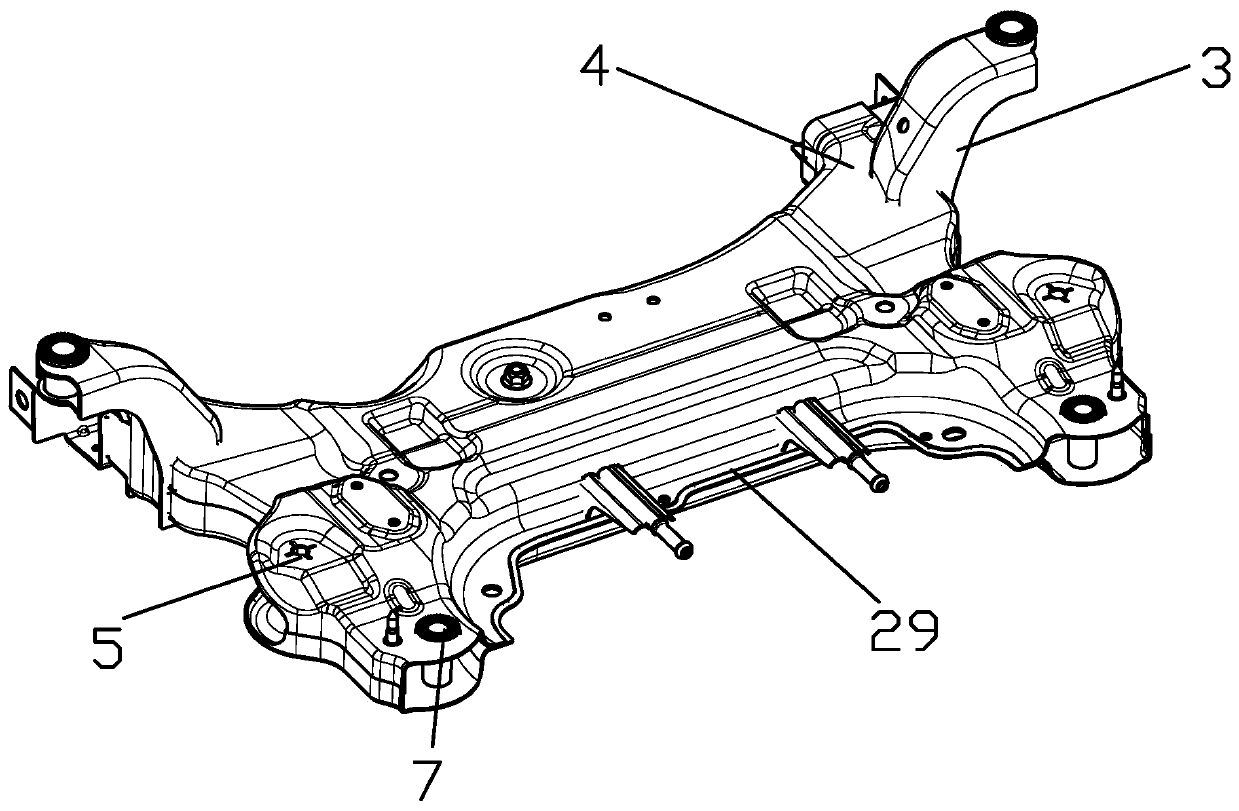

[0026] Example 1, such as Figure 1 to Figure 10 As shown, the front subframe assembly of the automobile includes the upper panel 1 of the front subframe and the lower panel 2 of the front subframe, and the upper panel 1 of the front subframe and the lower panel 2 of the front subframe respectively It has a downward lower flange 11 and an upward upper flange 21, the lower flange 11 and the upper flange 21 butt up and down so that the front sub-frame upper plate 1 and the front auxiliary frame The frame lower plate 2 encloses a rectangular box structure. The front part of the front sub-frame assembly has two opposite protrusions 4, the transition between the front part of the front sub-frame assembly and the protrusions 4 is smooth, and the front mounting bracket 3 is arranged on on the protruding part 4. The sides of the lower plate 2 of the front sub-frame are respectively provided with two opposite installation grooves 21, the front installation frame 3 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com