ABS composite with special odor and preparation method thereof

A composite material and special odor technology, applied in the field of polymer materials, can solve problems such as unpleasant and irritating odor, and achieve the effects of improving odor type and odor level, simple preparation process and reducing irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0028] Experimental Example 1: Preparation of Special Odor Masterbatch

[0029] Dissolve the odor regulator in Table 1 in an aqueous ethanol solution with a mass fraction of 20% to 60%; then physically blend it with the carrier ABS at a ratio of 0.01% to 1.5%, and then place it in a vacuum oven at 50°C for vacuum drying 24h, obtain ABS odor adjustment masterbatch; The ratio of its active ingredient is according to Table 1.

[0030] Table 1 Mass ratio of active ingredients in odor-adjusting masterbatch 1#~6#

[0031] 1# 2# 3# 4# 5# 6# ethyl isovalerate 7 Cis-3-Hexenol 2 3 Isoamyl acetate 8 p-methylbenzyl acetate 9 2,6-Nadien-1-ol 1 1 2-methoxy-4-allylphenol 9 3-Hydroxy-2-butanone 4 Isoeugenol 6 7 2,3-Butanedione 3 Proportion of total active ingredients in masterbatch 0.45 0.30 1.5 0.13 0.10 0.01

Embodiment 1~6

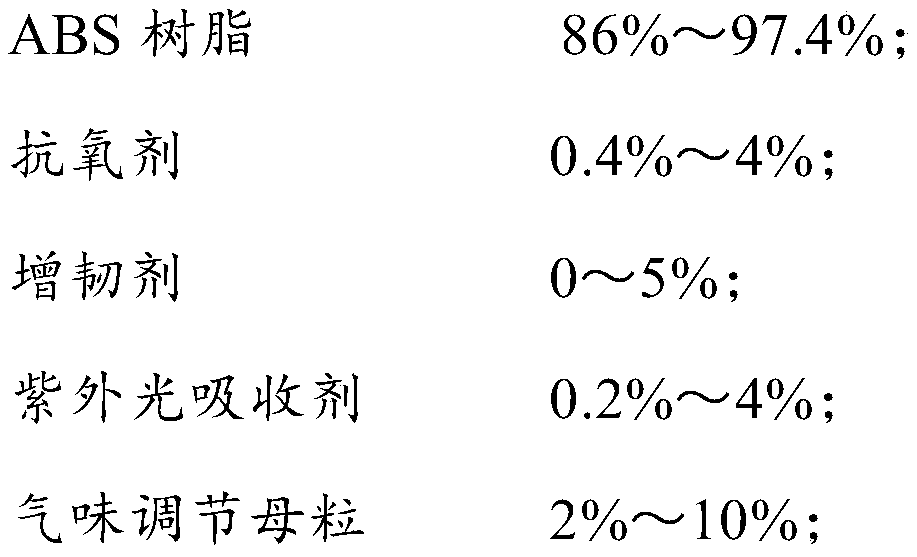

[0033] Table 2 shows the mass ratio of each component ratio in Examples 1-6 and Comparative Examples 1-2, wherein Examples 1-6 correspond to the use of 1# to 6# odor-adjusting masterbatches in sequence.

[0034] Parts by mass of each raw material in Table 2 Examples 1-6 and Comparative Examples 1-2

[0035] ABS resin Toughener antioxidant UV absorber Odor Adjusting Masterbatch Example 1 92 1 3.0 1.0 3(1#) Example 2 90 4 0.5 0.5 5(2#) Example 3 97 0.2 0.2 0.6 2(3#) Example 4 92 3 0.7 0.5 4(4#) Example 5 86 3 0.5 0.5 10(5#) Example 6 88 1 0.2 3.2 7.6(6#) Comparative example 1 99 - 0.5 0.5 - Comparative example 2 94 5 0.5 0.5 -

[0036] The specific preparation methods of Examples 1-6 are the same as those of Comparative Examples 1-2.

[0037] The raw materials are weighed according to the ratio of each component shown in Table 2, and after mixing uniformly in a high-speed mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com