Assembly type connecting method for steel bars of tunnel concrete lining structure

A connection method and concrete technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of burnt waterproof board, low degree of mechanization, and many construction workers, so as to improve construction accuracy, improve pass rate, and avoid secondary problems. The effect of lining water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

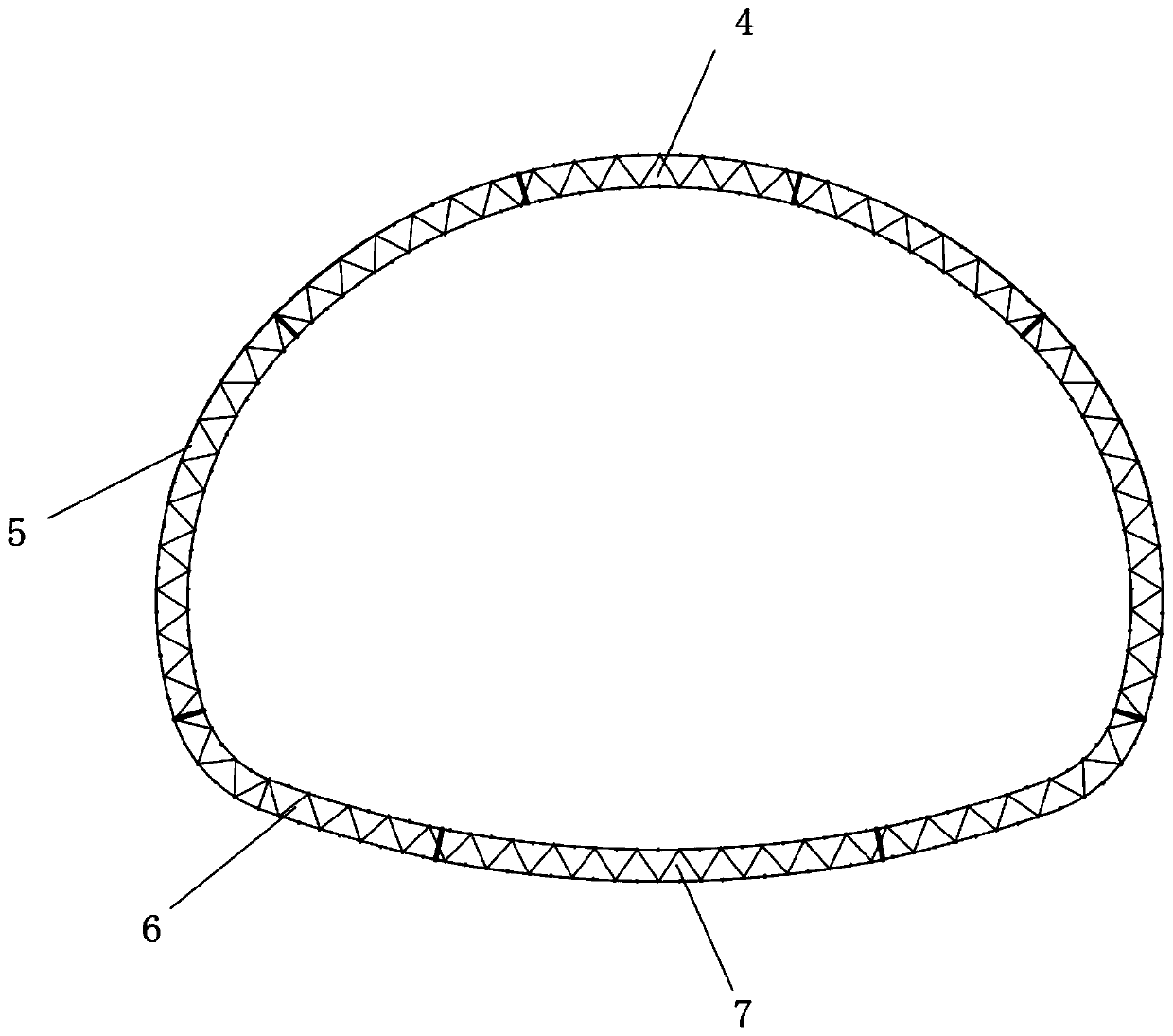

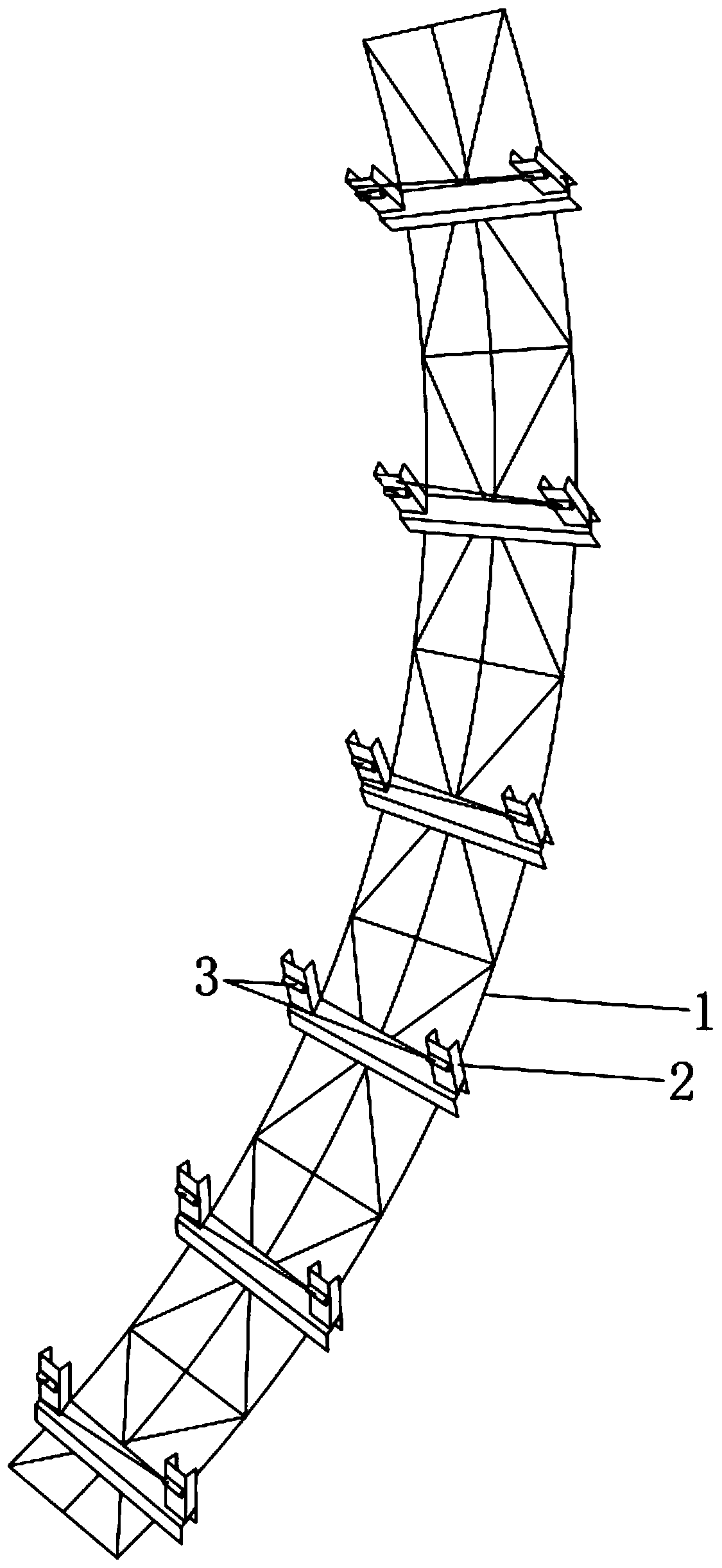

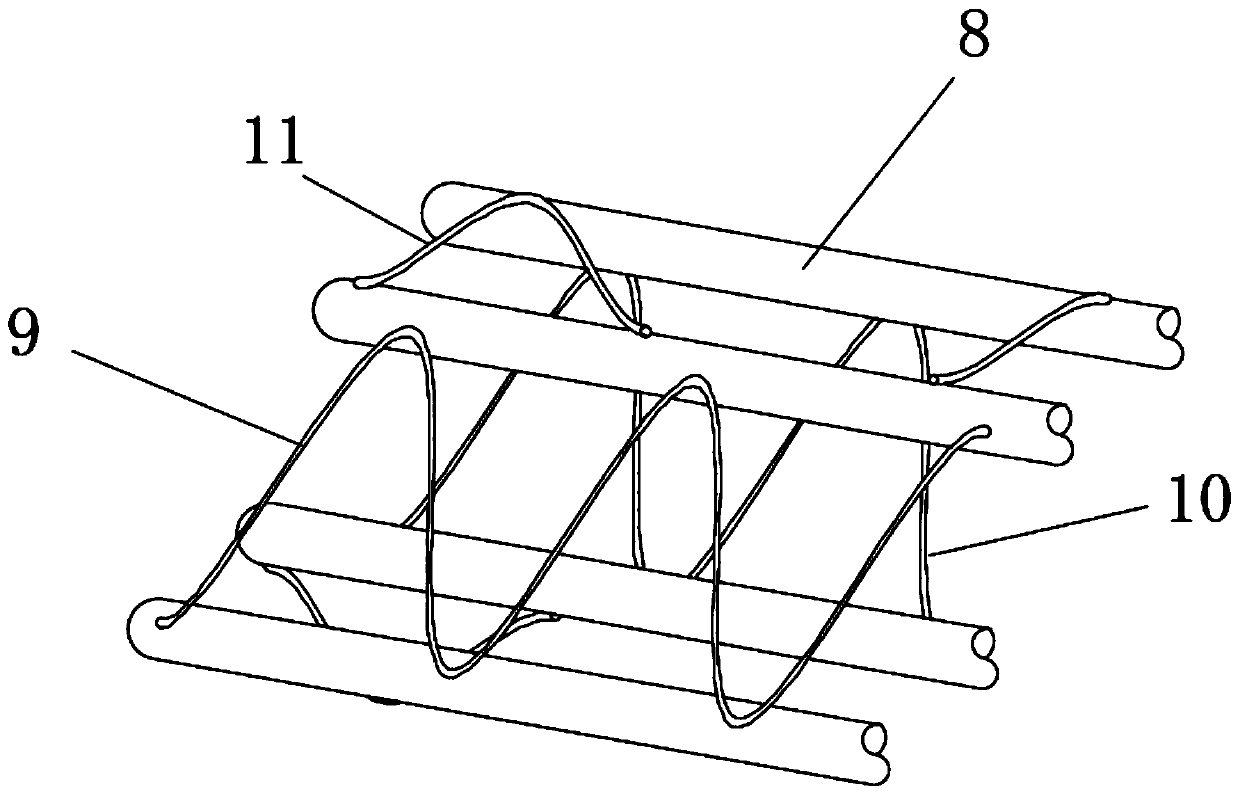

[0032] Such as Figure 1-6 As shown, a prefabricated connection method for concrete lining structural steel bars of a tunnel comprises the following steps:

[0033] Step A: According to the size of the tunnel, make positioning tire frames for each unit. The size of the positioning tire frames is designed according to the structure of the steel bars of each unit. After the processing of the positioning tire frames, paint the anti-rust paint on the positioning tire frames.

[0034] Step B: Preliminary processing of the raw material of the steel bar, through cold rolling and bending of the raw material of the steel bar, the steel bar is formed into a wave shape, and there are bent steel bars on both sides of the wave-shaped steel bar, and the bending degree of the curved steel bar is according to the bending of the positioning tire frame The degree of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com