Dynamic variable speed optimization control method considering efficiency of HMT (hydraulic mechanical transmission)

A technology for optimizing control and transmission, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problem of not considering the influence of HMT transmission drive power, etc., to improve fuel economy and transmission efficiency. The effect of improving and reducing the cost of agricultural production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

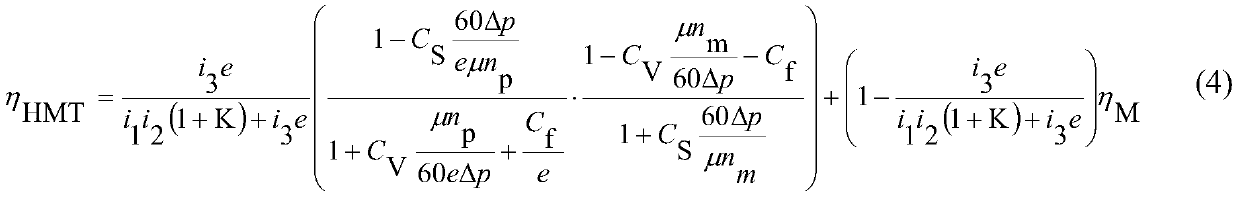

[0031] In this embodiment, a dynamic transmission optimization control method considering the efficiency of the HMT transmission, when the HMT transmission system is in a mechanical-hydraulic dual-flow transmission, in order to avoid the phenomenon of power cycling in the hydraulic circuit, the adjustment range of the pump displacement ratio is 0h <1; The specific method is as follows:

[0032] Step 1. Calculate the hydraulic power split ratio ρ of the transmission system of the HMT transmission according to formula (1) h :

[0033]

[0034] In formula (1), i 1 Input gear pair transmission ratio for hydrostatic transmission; i 2 Is the transmission ratio of the hydrostatic transmission output gear pair; i 3 Is the transmission ratio of the transfer shaft and the confluence shaft input gear pair; e is the displacement ratio of the hydraulic pump; K is the characteristic parameter of the confluence planetary gear train.

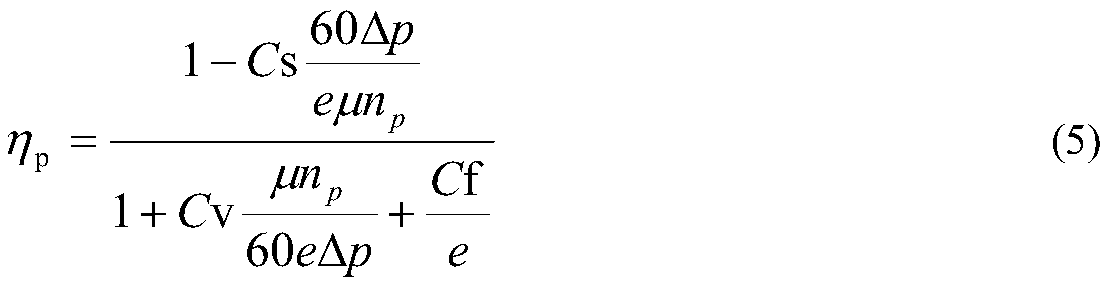

[0035] Step 2. Calculate the efficiency η of the hydraulic circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com